Precast Lifting Design

Often it is more important to have relevant experience in precast design, coupled with some good reliable design tools rather than a degree in structural or civil engineering.

As it is heavily related to the crane and rigging industries, lifting design is one of the few remaining structural designs that still operates predominantly on a working stress design model rather than limit state design. This is done largely to ensure that the risk of overloading of the lifting anchors is kept to a minimum.

Therefore, Safe Working Load of anchor > applied service load.

Also, care needs to be given to assess each load case including demoulding, storage, transportation and erection as the carnage and concrete strength could differ for each.

Flat panels can be relatively straight forward, but volumetric constructions add another dimension that can result in additional issues to overcome.[/vc_column_text][/vc_column][/vc_row]

Determination of Applied Service Load

Element weight, based on 2400-2500kg/m3 is the initial start point for any lifting design. However, there are a number of additional factors that need to be taken in to account:

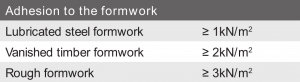

1. Suction between the concrete element and the formwork can vary depending on the material and geometry of the casting bed. For example:

These values are for flat casting beds only and additional factors need to be applied if the geometry is different.

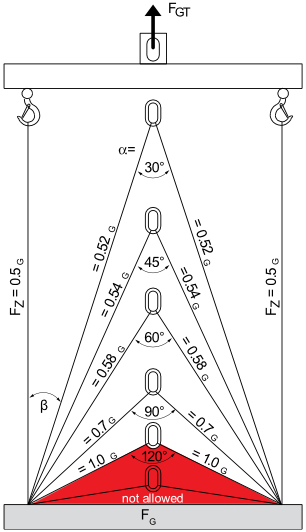

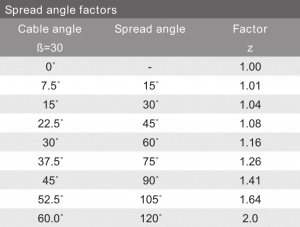

2. Sling angle factor for the rigging also affects the amplitude of the service load on the anchor and is often directly affected by the amount of height clearance at the precast factory.

It is generally accepted that a sling angle (α) of 60 degrees (β=30) is the best compromise and therefore tends to be the default for most lifting designs.

Dynamic Impact Factor

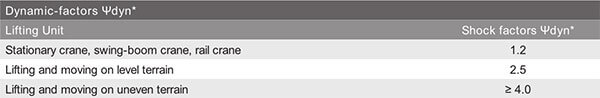

Another important consideration is estimating the effect of dynamic impact on the lifting system.

This is based on engineering judgement about the type of crane and ground conditions. A fixed gantry crane will have much less dynamic impact than a crawler crane moving over uneven ground.

* If other values from reliable tests or through proven experience are available for Ψdyn then these may be used for calculation.

Determination of Safe Working Load

Each anchor is allocated a load class, but this can give a misleading level of confidence as it is only the steel capacity and the concrete capacity can be much lower.

Steel Capacity

The steel capacity is stamped on every anchor head as is determined by taking the characteristic (5% fractile) strength of the anchor and dividing it by 3. Therefore, a 5T anchor will typically survive a load of 15T before it breaks.

Concrete Capacity

There are a few different concrete failure mechanisms that can occur and for a detailed analysis you should refer to VDI BV-BS 6205 or CEN/TS 1992-4. However, concrete cone failure is the most well-known and is a function of the concrete strength at time of lift, the edge distance and the embedment depth of the anchor. The general safety factor given to concrete failure mechanisms is 2.5 against the characteristic (5% fractile) strength of the concrete. It is lower than the steel as it is generally unaffected by multiple uses.

For a detailed analysis of your anchor capacity, please consult the Halfen Moment’s engineering team.

Related Articles You May Be Interested