Never Make Safety Vulnerable For Any Reasons

An alarming change to common practices in coupler length are sweeping across India.

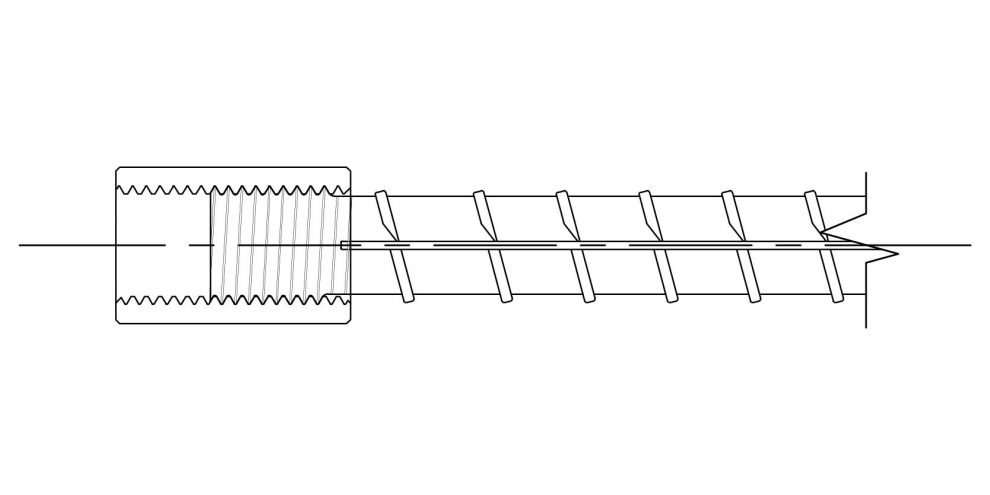

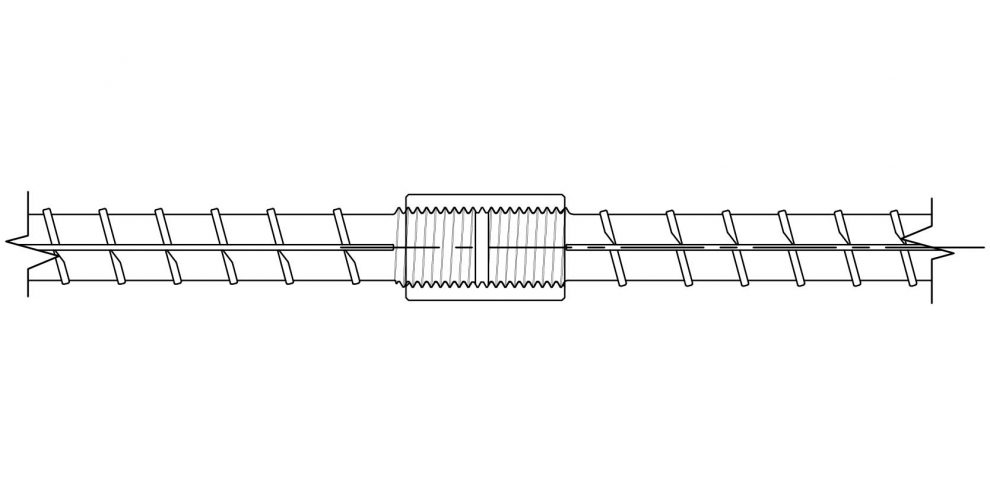

Couplers, or Mechanical Splices as are they are also called, are becoming a common method for connecting reinforcing bars together. However, from what we can tell, the way that couplers work is still greatly misunderstood by the vast majority of the Structural Engineering Industry. Therefore, the majority of Structural Engineers happily take the lead of the various standards organisations around the world who have written standards to empirically determine the performance of a system, but this has led to 2 key problems that jeopardizes the structural integrity of our concrete structures.

1. The samples are prepared by the supplier of the system and are usually prepared and installed perfectly. For obvious reasons, this perfect installation is not always possible on site due to manufacturing tolerances and site conditions.

2. The global standards and certification bodies that exist today, are mainly focussed on the initial proof of concept of a system rather than the on-going quality control. Even those bodies that have some element of on-going quality control do not simulate the on-site conditions.

In short, there is no “policing” of the quality control at site level.

For these reasons, most certified suppliers build in some additional robustness to allow for the issues that commonly occur on site, namely:

1. Imperfect thread lengths. There is a tolerance on the thread length that can easily result in the engagement of the 2 bars being 45% : 55% instead of the tested 50% : 50%.

2. Gaps between the rebars. In the case of prefabricated pile cages, it is impossible to have all the bars in exactly the same plane and as such a gap of up to 20mm between 2 bars could easily occur, again reducing the engagement of the thread.

As you can see, both of these will result in the same issue, that the engagement of the thread on the end of the rebar into the coupler will be compromised and a smaller engagement will occur. Thread length is defined to ensure that the amount of load transferred to each thread does not exceed the stripping capacity of that thread. If the stripping capacity is exceeded, then the failure mechanism will change to a stripping failure.

We therefore need to provide a sufficient safety factor against this that will also cover the typical onsite issues shown above.

In India, we have seen an alarming trend where people are marketing a “2D” coupler system where the length of the coupler has been reduced by about 20% to 2x bar diameter. It does pass all the necessary tests in the standard but does not perform well when you try to mimic the onsite problems listed above. We are sure it is only a matter of time before similar products appear in other countries as people strive for cost reduction, but we need to be aware that in this case, cost reduction is directly reducing the safety of the system.

We understand these issues and recently conducted some comparative tests and found that the 2D coupler strips with a bar gap of only 15mm, whereas the longer standard coupler that is marketed by certified suppliers continues to work properly well beyond this limit. This means that the total safety factor on the “2D” coupler is less than 20% even if the installation is performed perfectly.

Never Compromise On Safety!

Let Us Drop You A Call For Consultation. For Free.

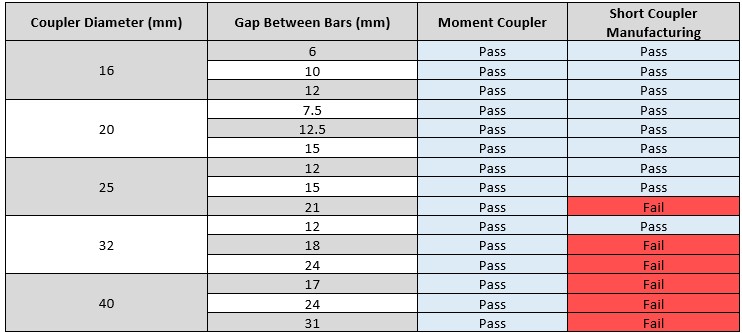

Impact Of Coupler Strength With Reduced Embedment

- Gaps between the bars of greater than 15mm fail with the shorter coupler, but still pass with the Moment coupler.

- 40mm coupler with a reduced engagement of just 19% will result in a failure using the shorter coupler.

- There is no factor of safety against failure of typical installation issues.

We should not be comfortable with this reduction in total structural safety and strongly urge structural engineers to investigate these topics more thoroughly and ensure the future robustness of our built environment for future generations.

Related Articles You May Be Interested

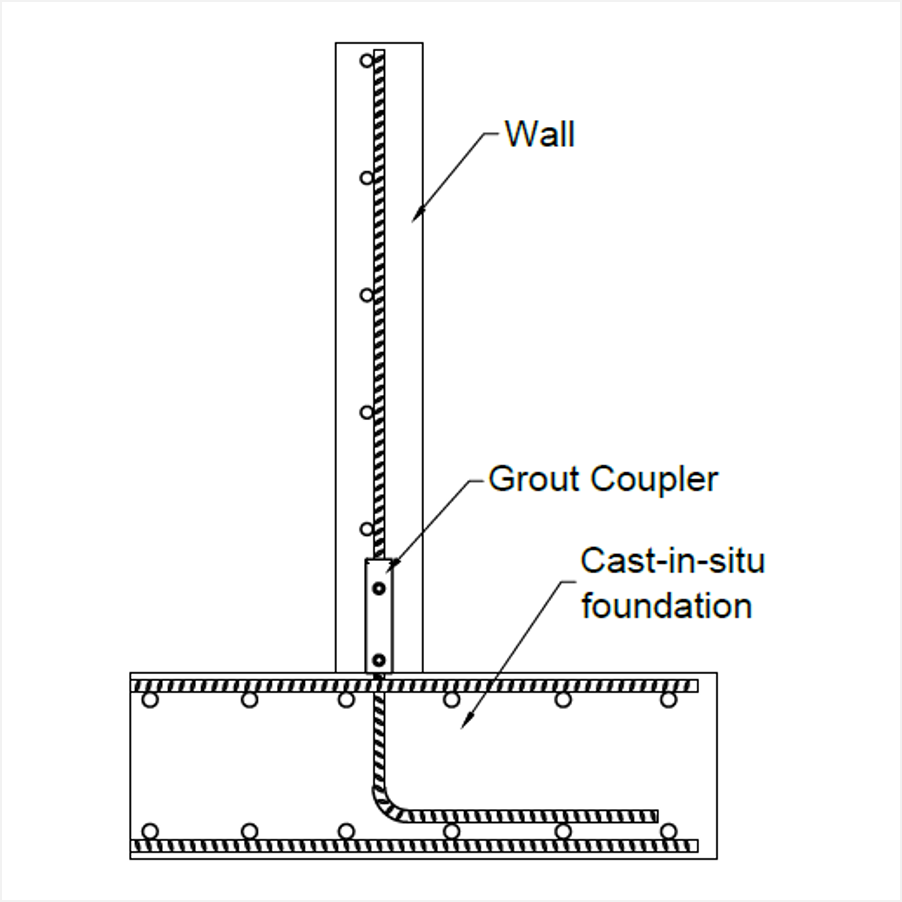

3 Ways To Connect Precast Concrete Wall To Foundation Effortlessly

When considering the best options for your building project, the benefits of going with a concrete wall panel system are many. By choosing a concrete wall panel system, these features may provide advantages that can be enjoyed by owners, architects, engineers and contractors on site. The benefits include:

- Energy efficiency

- Environmental reliability

- Aesthetically attractive

- Minimal preservation

- Speediness of construction

- Onsite Productivity

To enjoy the benefits, we must make sure the connection between the precast elements and of the precast walls to foundation is robust enough to ensure the safety and integrity of the structure. Here are 3 main ways to connect precast wall panels to foundation.

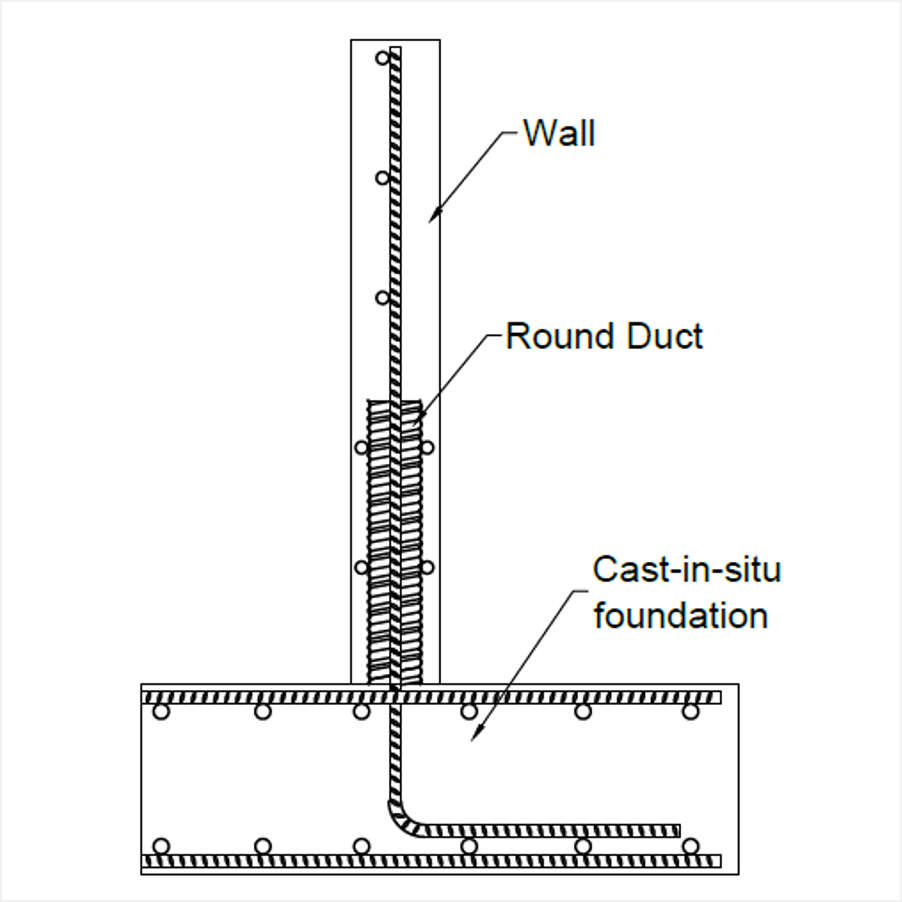

Corrugated Duct

Casting Corrugated Duct into the precast element is the traditional method to connect precast walls to foundation. Corrugated duct is used as a hole former for a variety of precast and cast-in-situ concrete works. The hot dipped galvanized metal duct is strong and durable for casting into precast walls and then to be connected with rebars from the foundation.

Although duct has been a commonly used method for precast connections, one of the major disadvantages of duct application is the huge amount of grout needed to fill up the duct in order to secure the connection between the precast wall and foundation.

Eventually, this traditional method will increase the cost and time of the overall construction.

Grout Coupler

Specifically for precast connections, Grout Coupler can be used for connecting precast walls, columns, beams either horizontally or vertically. The most popular connections used with Grout Coupler are:

- Precast concrete column to foundation connection

- Precast column to column connection

- Precast beam to column connection

- Precast wall to foundation connection

- Precast wall to wall connection

The rebars protruding from the foundation are simply inserted into the grout coupler, which has been casted in the precast wall. When pumped with MOMENT’s proprietary 100MPa grout, the grout coupler system is a bar break technology and is capable of carrying very high bar loads regardless of the rib profile on the reinforcing bar.

Although this is not the most popular application of grout coupler but the application of grout coupler for precast wall to foundation is still widely accepted in the market.

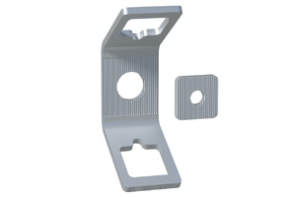

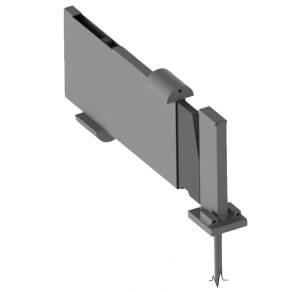

Precast Shoe

Mainly used for connecting precast column and foundation, Precast Shoe can also be used to connect precast wall panel to foundation. They are especially suitable for anchoring in flat structures such as the foundations or walls that have sufficiently large edge distance.

The advantage of this precast system with screw connection is the quick assembly. The connection is easy to adjust with a healthy tolerance and immediately loadable so that bracing is not required which results in less labour at site. However, they are not specifically designed for walls and therefore have a limitation on the wall thickness and thin walls cannot be connected using this type of product.

The system comprises of the precast shoe (cast into the precast wall) and the suitable anchor bolts (cast into the foundation) for the foundation base. Both elements are joined by load bearing nuts during assembly on site.

Stop Compromising on Quality.

Let Us Drop You A Call For Consultation. For Free.

Related Articles You May Be Interested

The Secret Of Precast Wall To Wall Connection

There are a number of challenges when connecting precast walls, namely:

1. Connections are wet, so require temporary bracing.

2. Installation time can be lengthy, so crane time is not optimised.

3. Connecting of both vertical and horizontal rebar connections is practically impossible due to the stiffness of the rebars.

At Leviat, we have a solution for all of these challenges, but here we would like to address the third one as it is arguably the most important fundamental.

So What is MOMENT Loop Box?

MOMENT Loop Box are used for connecting precast wall to wall or to a column. After casting to the formwork, the precaster will just need to remove the tape and release the loop into the operating position. A vertical rebar (sometimes called a trimmer or cottering bar) is installed into the joint through the wire loops. Lastly, cementitious grout is poured or pumped into the joint.

There are 3 types of MOMENT Loop Box – Multi, Double and Single Loop Box.

Loop boxes are installed to the formwork according to the spacing specified by the designer, before the panel is cast.

A vertical rebar is installed into a joint through the wire loops of both precast panels before grouting.

Key Advantages

Fully compliant with EN1992-1-1 (Eurocode 2), MOMENT Loop Box has been tested in accredited test labs to simulate performance in various application, transmitting forces from three directions (perpendicular, parallel and transverse load).

Below are the key advantages of loop box when compared with the traditional method of connecting precast walls:

- Flexible installation method for seamless connection between precast wall

- Reduces the total installation time by 50% with less labour

- Eliminates the clashes between U-bars from the traditional method

- Customizable length of steel box and wire loops

- Easy installation of loop box to the formwork with the option of magnet

Multi loop box acts as a shear key and simplifies the design of the formwork.

Making precast wall connection easier and faster

Key Features

Consists of high-strength, galvanized steel casing and wire loops, loop boxes connect precast walls in an efficient and time saving method. Below are the key features of loop box:

Galvanized Steel Box

A robust sheet-steel box and wire loops contain the plastic latch and wire loops

Plastic Latch

Specially designed plastic latch to secure the wire loops in position for good anchorage embedment for in concrete

Flexible wire loops

Galvanized wire loops transmit force into the concrete and connect 2 walls to each other. Loops can be bent out and straightened with a hammer claw, screwdriver or a nail.

MOMENT Loop Box Makes Wall Connection Easier.

Let Us Drop You A Call For Consultation. For Free.

Related Articles You May Be Interested

Precast Connections You Must Know In 2024

Structural Connections For Precast Concrete Buildings

There are a number of ways of doing this such as via:

• Grouted Coupler for precasts walls and columns to foundations connection

• Wire Loop Box for precast walls connection

• Precast Coupler for precast elements connection

• Dowel Systems for precast beam to column connection

Apply the latest technology of precast connections from Leviat, available in Malaysia, Singapore, India & the Philippines. Discover more now!

MOMENT Grout Coupler

MOMENT Loop Box

They are usually used to connect 2 adjacent precast panels together, where the interlocking rebar and wire loops provides robustness in the event of an Earthquake to ensure that grout degradation would not result in complete collapse.

MOMENT Connection Loop

In order to connect 2 precast elements, both precast elements has to be cast with the MOMENT Connection Loop at the wall. A rebar will then be inserted through the intersection of 2 loops. After placing the rebar, the gap between the precast elements will need to be grouted using a 40Mpa or 70MPa non shrink grout depending on the application. Material strength of the MOMENT Connection Loop is 1770N/mm and complies to EN12385-4:2002+A1.

HEK Precast Coupler

Cast-in DEMU Fixing anchors i.e. T-FIXX®, bolt or bar anchors transfer the tension and shear force into the precast element.

The main advantage of the system is the fast and efficient positioning of precast elements. The connection can be subjected to load immediately after installation. This results in a substantial improvement in construction time.

Invisible Connections

But by keeping the grouting to a minimum, one such technology – Invisible Connections – has revolutionized the use of precast all throughout Northern Europe; it is a patented system, with its origins in Norway, to connect precast concrete without use of corbels or steel angles, and is used extensively throughout Europe due to the independently tested and certified European Technical Approval (ETA [4]) that provides engineers with peace of mind about the capacities.

The product range of Invisible Connections consists mainly of TSS Telescopic Stair Connectors & BSF Telescopic Beam Connectors.

Another topic relating to Invisible Connections will be covered as a future topic in our Academy site.

There are many good technologies available, but a dependence on local testing and local reference projects will hinder and slow down their introduction. An increased readiness to accept the certification schemes for prequalification that exist overseas such as ETA[4] and ICC certification where appropriate, will mean that the technologies can help keep pace with the requirements of the precast industry.

Stop Compromising on Quality.

Let Us Drop You A Call For Consultation. For Free.

Related Articles You May Be Interested

Your Only Rebar Coupler For Precast Connections

The connection between precast concrete is a safety critical component in today’s structural precast construction. The success of this construction method goes beyond the structural performance of precast beams and columns; it also includes the performance of the precast connection. For the connection, the performance is not only limited to the structural robustness, but also embodies simplicity and productivity during the erection process. The connection types employed will not only affect the construction cost and speed but also have an impact on the sections that can be used via the ability for forces and moments to be redistributed throughout the finished structure. Moment Grout Coupler, consists of a one piece design, is a rebar coupler designed for precast connections. Compliant with ISO 15835, each grout coupler combines the benefits of the Moment JT threaded system and will achieve barbreak when used together with Moment’s proprietary 100MPa grout.* Specifically for precast connections, Grout Coupler can be used for connecting precast walls, columns, beams either horizontally or vertically. The most popular connections used with Grout Coupler are: For this type of connection, the high tensile steel starter bars are left protruding from the foundation. After that, a precast column with vertical sleeves at the end is placed over the starter bars. The sleeves are the filled in with grout to provide a connection. This connection has the ability to provide moment resistance at the connection between column end to footing. Additional technologies such as precast shoes can then be used to eliminate the need for propping. Similar to the above application, this enables the launching of one column section on top of another one whilst providing full moment continuity across the joint. This is specifically important on projects with large column sections as the height of the element is often limited to less than 1 storey because of crane capacity limits. You can use grout couplers to overcome one of the biggest challenges in precast concrete construction; a moment resisting frame. In this application, you provide clearance holes through the precast column and use a grouted coupler to provide full continuity through the precast column. To broaden the field of application, two product types are available: Full Grout Coupler and Half Grout Coupler. The rebars used with a Full Grout Coupler require no bar end preparation, such as threading, and are simply inserted to meet at the nominal centre point of the coupler. For more information on Moment Grout Coupler, please contact our offices where we can showcase you the actual Grout Coupler as well as our latest innovative precast accessories. *Lower grout grades might be possible, but it depends on the rib profile of the individual rebar supplier.Ideal Coupler For Precast Connections

1. Precast Concrete Column To Foundation Connection

2. Precast Column To Column Connection

3. Precast Beam To Column Connection

Connect Precast Elements The Easy Way.

Let Us Drop You A Call For Consultation. For Free.

Related Articles You May Be Interested

How To Connect ‘Mistakenly Shortened Rebars’ At Site?

There are 2 common methods to connect reinforcement bars. The traditional way of connecting rebar is by overlapping 2 rebars, with typical lap lengths of between 30 and 50 times the diameter of the rebar in accordance with EN1992-1-1. The modern way of connecting rebars is by using a mechanical splice system; a mechanical connection between two pieces of rebar that enable the bars to behave in a manner similar to continuous length of rebar. Most mechanical splices join rebar end-to-end along with the rebar threads, providing many of the advantages of a continuous piece of rebar, which is more reliable. Read more: Mechanical Splices VS Lap Splicing Like any other engineering problem, this situation may have other solutions like welding, drilling in additional rebar, depending on the site conditions, codes, materials used and the structure that is going to rest on this foundation. However, the best way to connect this is the Moment Bolt Coupler (MBC), a bolted coupler which does not require any rebar preparation, designed for the connection of two rebars which haven’t been previously threaded. • No threading required. Installation can be done by using a wrench.MBC- The Ideal Coupler for Remedial & Repair Works

If the rebar lap length was shortened by mistake, we will not be able to connect both rebars if:

1) The lap length is less than that specified for a particular application.

2) There is no way we can thread on either side of the rebars at site/ the rebars are being planted vertically

Each MBC coupler features a serrated hollow body which will grip the rebar. A number of bolts along one side will press the bar against the serrations and lock both bar ends and complete the connection.Bolts Designed to Shear Off at a Specified Torque

MBC coupler is a cost effective method of joining reinforcing bars, particularly when the fixed bar is already in place and there is insufficient space for a hydraulic swaging press. Below are the benefits of MBC coupler.

• Bar ends are supported within the coupler by reversed teeth on the internal wall, and as the lock shear bolts are tightened, the conical ends embed themselves into the bar and press the bar on to the teeth.

• Excellent for remedial & repair works where one bar is already fixed in concrete.

• Capacity load higher than 108% characteristic yield strength of grade 500 reinforcing bar.

Nut runner is strongly recommended to tighten the bolts for higher precision and faster installation.The Simplest Way To Join Short Rebars.

Let Us Drop You A Call For A Consultation. For Free.

Related Articles You May Be Interested

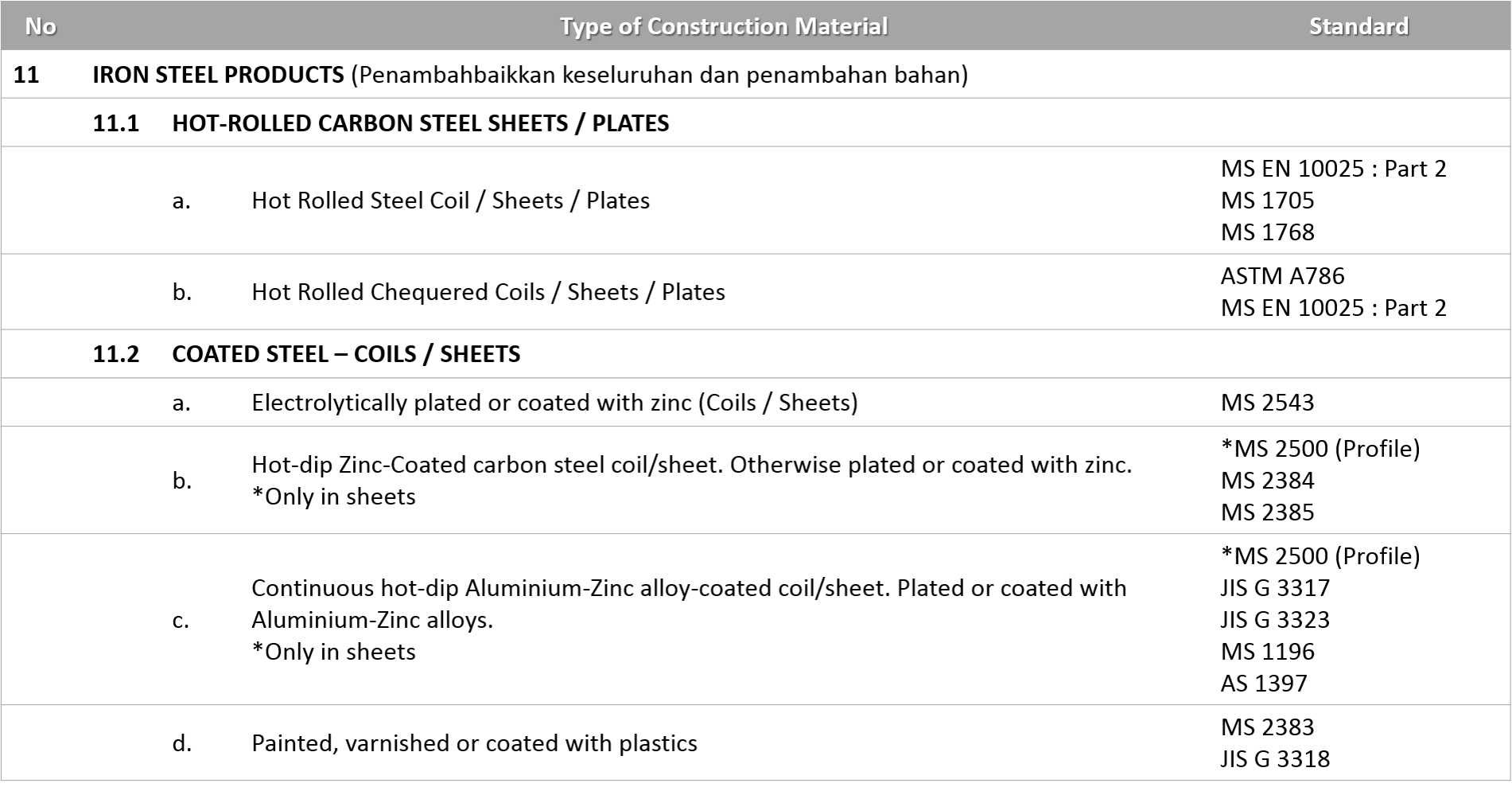

[First in Malaysia] CIDB CREAM Certified MOMENT Mechanical Splicing System

Download our CREAM Certificate here Today, the demand for efficient splicing systems has become increasingly important due to the increased construction complexities, design requirements, escalating costs and limitations of traditional lap splicing methods. This has driven the need for alternatives that is able to provide both structural robustness and cost effectiveness.

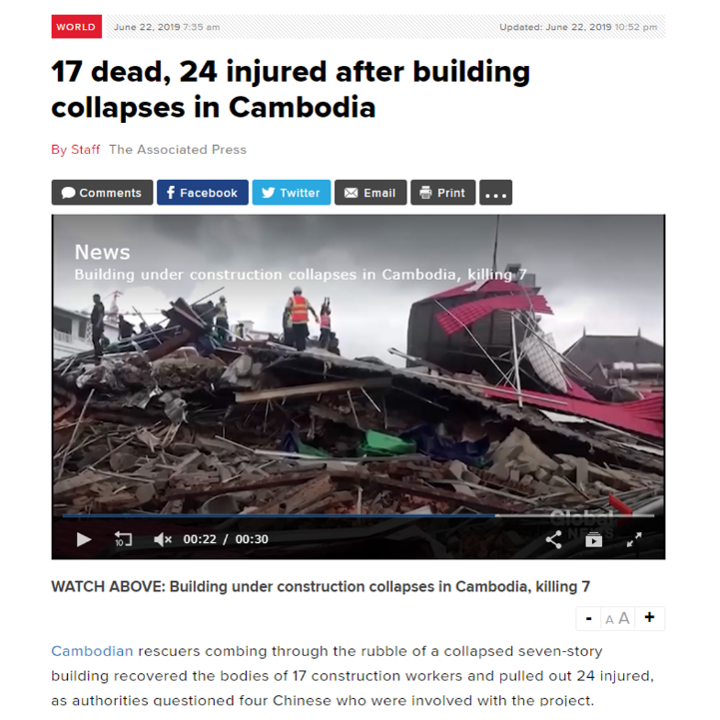

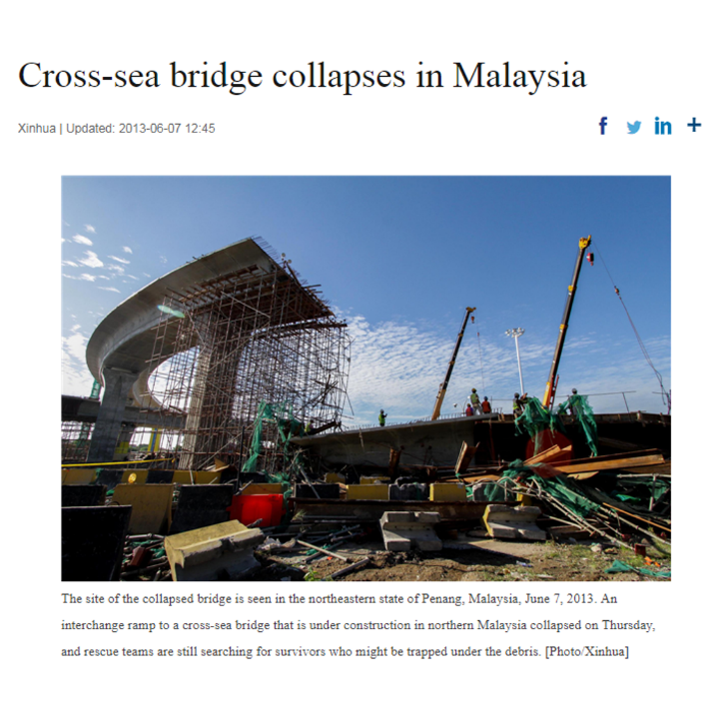

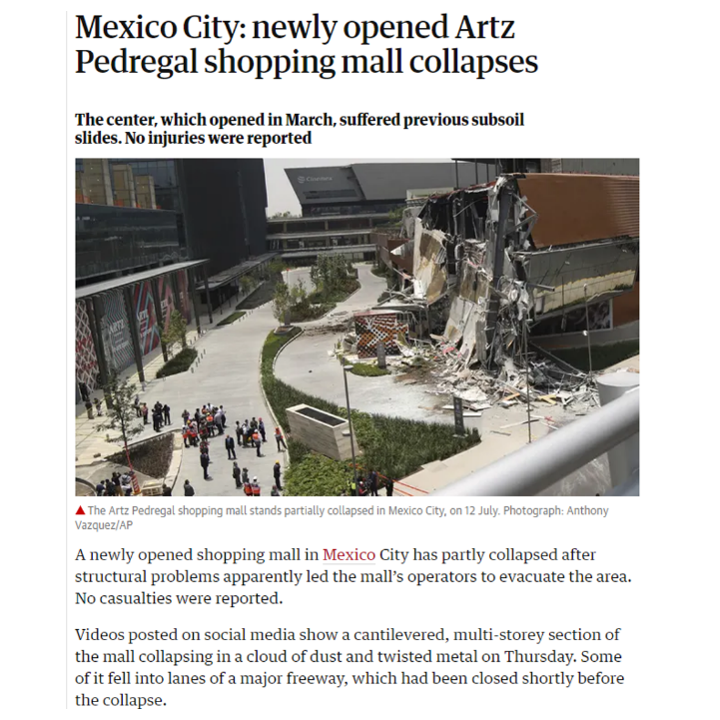

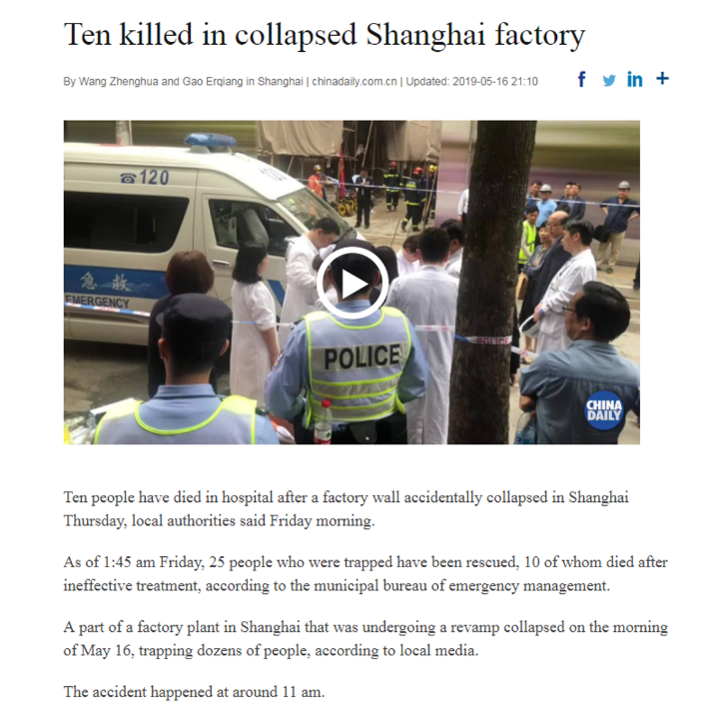

With all these catastrophes all around the world, Malaysia has been exposed to the stark reality that we can no longer be considered immune to such tragedies of tragic proportions in terms of lives lost, property destruction and even economic collapse. The government and regulatory bodies have therefore taken serious steps in reviewing current building regulations and codes, to enable structural engineers and constructors to take immediate and necessary precautions to ensure the safety of their design as they are liable if anything happened to the buildings (refer provisions under CIDB act below). MOMENT JT mechanical connections conform fully with applicable codes including BS 8110 Pt 1:1997 Clause 3.12.8.16.2 Bar in Tension and ISO 15835, providing defined ductile behaviour and performing like a continuous reinforcing bar. In reinforced concrete design, the Structural Engineer is faced with the task of determining where and how reinforcing bars must be spliced in a structure. This must be done to ensure that the national regulations are adhered to and also to make sure that the structure will not suffer a progressive collapse if overloaded. Due to the minimum connection strength required, it is generally assumed in design that the occurrence of a mechanical connection of two reinforcing bars does not result in a reduction of the anticipated structural strength nor the longitudinal ductility of the reinforcing steel. This would maintain the properties which the reinforced concrete member would have had with a continuous unspliced bar. That is, it is assumed that the use of a mechanical connection does not introduce a structural weakness that could jeopardize the overall structural performance. Design requirements of the applicable codes as in BS 8110 and EN 1992-1 generally assume a minimum connection strength but are silent on the details about test methods and conformity assessment. ISO 15835, which is used as the basis for CREAM’s assessment covers all aspects of coupler production and assessment including: In a structure undergoing inelastic deformations during an earthquake, the tensile stresses in reinforcements may approach the tensile strength of the reinforcements. The requirements for MOMENT JT mechanical splices are intended to avoid a splice failure when the reinforcement is subjected to expected stress levels in the plastic regions. In addition to that, in plastic hinge regions, the first part to fail is the concrete where excessive spalling occurs. Once the concrete spalls, the lap splice behaviour is severely compromised, whereas the mechanical splice behaviour remains intact. In seismic consideration: MOMENT JT connection offers many advantages to the designer and builder to help improve the design and reduce construction time and cost while providing versatility and can help to solve many construction problems today. As Malaysia progresses in nation-building, federal governance, regulations and codes for construction regarding seismic frame construction become more stringent, MOMENT JT connections, the proven mechanical splice method, provides you with the ability to design and build concrete structures to withstand the test of time.Why So Many Construction Structures Collapsed- How Safe Are We?

*MS 2500 (Profile) Enforced 1 December 2016 Consultation with industry and testing body on 5 January 2017: Testing requirements for design requirements are not clearly stated. The meeting agreed to adopt AS4600 and EN9590 Part 5 in addition to MS2500. CIDB has submitted the MS2500 revise application to DSM on January 6, 2017.MOMENT JT Connection

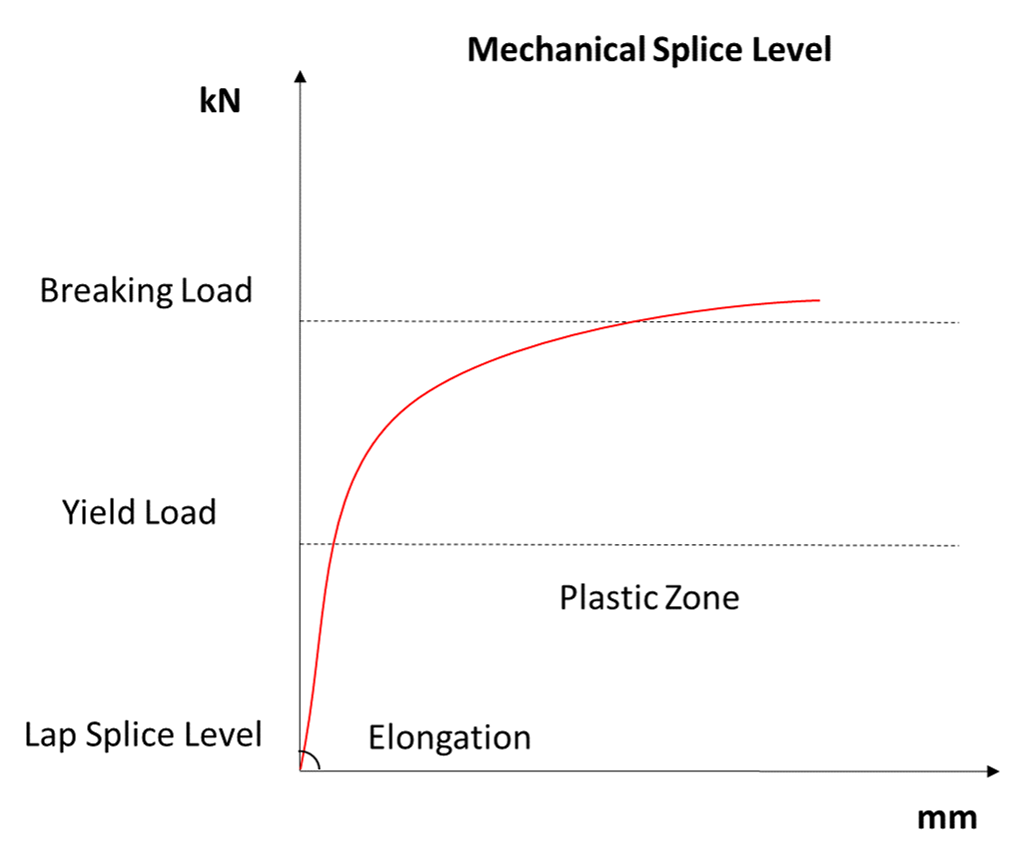

Fig 1: MOMENT JT connections perform beyond the yield point of the bar whereas Lap Splices are only defined in the elastic area. This indicates that the MOMENT JT connection which works as a continuous bar provides additional strength and safety all around independent of the quality of the surrounding concrete.Design Codes and Specifications

MOMENT JT Connection and Seismic Design

Lap Splices (2011 – Turkey) – Concrete spalling results in lower or zero capacity as the concrete that is critical in the load transfer has disappeared.

Mechanical Splices (2017 – Mexico City) – Concrete spalling has no effect on capacity as the mechanical connection is still present.

Conclusion

Locally Approved Couplers For Quality Connections.

Let Us Drop You A Call For Consultation. For Free.

Related Products You May Be Interested

The Missing Link Of Quality

With the advent of Industrialized Building System (IBS), there is one aspect of the supply chain that has remained unregulated and subject to risk of poor quality solutions creeping in to the market place that might be structurally unsound. This largely comes from the fact that the metallurgy of these connections is critical to their suitability, so the selection of the right steel is vital to ensure their performance.

Metallurgy plays a crucial role in enabling sustainability

When construction methods changed to IBS, there was a sudden influx of new technologies to assist in the connections of the precast element; but there is a natural lag before product codes can catch up and provide the same level of total robustness as traditional construction methods.

IBS approach has been widely adopted, as it reduces construction time frames compared with conventional methods.

While the scope of BS8110 did not cover all of these new connections, at least there were some minimum requirements for the mechanical splicing of reinforcing bars.

Why is CREAM Certification important?

Ever since the adoption of Eurocode 2 (EN 1992-1-1) in 2015 the requirements for these mechanical connections became lost largely due to the fact that Europe has separate National regulations for these items provided by such organisations as CARES in UK and AFCAB in France.

Thankfully, the CIDB in Malaysia realised that there was a gap and has identified CREAM* as a certification body who can provide the same service locally to provide confidence to the users, purchasers and specifiers of constructional steels and to ensure its safety and reliability, government, private and/or non-profit bodies. However, for other more advanced technologies, where no standards exist today, this type of certification is not possible as CREAM needs a standard to audit against.

For these the engineering community needs to better understand the metallurgy and ensure that the products are fit for purpose. But at least for mechanical splices, the publication of ISO 15835:2018 means that CREAM certification is now possible.

*The Construction Research Institute of Malaysia (CREAM) is a research and development (R & D) institution for the construction industry in Malaysia. Committed to ensure that R & D programs meet the needs and requirements of the national construction industry by implementing quality management systems that meet MS ISO 9001.

Related Articles You May Be Interested

What Everyone Is Saying About ECRL?

The East Coast Rail Link (ECRL) (Malay: Laluan Rel Pantai Timur) is a planned standard gauge double-track railway link infrastructure project. The construction began in August 2017 was suspended from July 2018 to April 2019. The project was continue with revised construction cost and southern alignment of the rail link.

6 States Combined

ECRL will be connecting 6 different states starting from Selangor going to Wilayah Persekutuan Putrajaya, Negeri Sembilan, Pahang, Terengganu and stops at Kelantan. This project effectively connects the West Malaysia & East Malaysia with efficient time & cost management for customers.

14 Passengers Only Stations

There will be a total of 14 passengers only stations, 1 freight only station and 5 combined passengers & freight stations. MRL aims to ensure customers’ comfort towards the whole journey.

4 Hours from WP Putrajaya to Kota Bahru, Kelantan and Vice Versa

This project that costs RM44 billion cuts the travelling time of West-East Malaysia to 4-hour with total of 640km versus average of 7-hour drive for 474km. Now we can avoid long ride during festive seasons and opt for cheaper options than flying on plane or helicopter.

3 Interchange Stations –KTMB, ERL and MRT

Any railway project will not be completed without interchange stations – and ECRL will not missed the opportunity for increase accessibility for their potential users. Currently, the project aims to have 3 interchange stations with Keretapi Tanah Melayu Berhad (KTMB), Express Rail Link (ERL) presently connects KL Sentral and KLIA and Mass Rapid Transit (MRT) that connects Sg. Buloh to/from Kajang.

2 Services Provided – Passenger Train & Freight Train

There will be 2 service provided by ECRL namely Passenger Train that can speeds up to 160km/h and Freight Train that speeds up to 80km/h. This development too will include with double tracking for simultaneous ride to and fro at any point of the track.

1 Aim – To Stimulate Economic Growth Along ECRL Corridor

The development of the ECRL will encourage economic growth along the corridor, many business opportunities will rise with this project. Upon announcement of this project, there are 1,321 submissions from Construction Industry Development Board (CIDB), break down to – 859 submissions or 65% are of G7 category of CIDB-rated companies, 134 submissions from Grade G5, 132 submissions from Grade G4 and 104 submissions and 92 submissions from Grade G3 and Grade G6 respectively. The project also encourages bumiputera participation that consists of 994 bumiputera engineering and construction companies representing 75.25% of the overall registration.

Related Articles You May Be Interested

Top 3 Building Products for Railway Construction You Should be Talking About

Rail transport is still today one of the main transportation method in many countries and remains a key driver of development and socio-economic rebalancing in local areas. The need to create new and strategically important routes has made railway construction one of the most relevant sectors on the global scene.

To ensure high levels of transport safety, railway builders and construction partners involved in this sector must adhere to strict safety standards to use quality construction accessories and innovation to optimise construction for a safer and cost effective railway.

You will always find the following products during the construction of any railway project:

• Post Tensioning System to allow longer span of beams for bridges so less pillars are needed.

• Cast in Channel to fix and support railway services especially if overhead electrification is selected.

• Rebar Coupler to simplify the design and construction of reinforced concrete and reduce rebar congestion.

Post Tensioning System

The use of post tensioning system in the beams in railway construction allows a longer span of bridges which reduces the number of pillar required. With lesser pillars, there will be less foundation which eventually reduce cost and also construction time. This minimises the interruption to the existing landscape and will give the planner or designers to have more flexibility and options in plotting out the routes. There is a huge impact to the buildability especially in most MRT/LRT railway projects when they are built in Metropolitan cities which are highly congested with existing services and landscape.

Cast-In Channel

Cast-in channel provides flexibility in fixing points, therefore future proofing the construction to allow for changes in the arrangement of the services. The use of cast in channel in fixing the services gives a shorter installation time and therefore reduces the duration of the project. The superb tolerances feature make the installation faster and easier.

Rebar Coupler

Rebar couplers offer a full strength connection. They are suitable for projects of any size, including those requiring a high volume of couplers, such as road and rail bridges where fatigue performance may also be a factor. The use of couplers reduces the congestion of reinforcement bars and this will enhance the buildability which also means speeding up the construction progress.

Halfen Moment has always invested in and consolidating know-how, by providing innovative building solutions for our customers to develop railway construction projects. Contact us today to start improve your project productivity cost effectively!

Related Articles You May Be Interested