Precast Connection and Accessories Supplies

We offer an unrivalled service to the precast concrete industry of Malaysia, Singapore, India and Philippines. Our product portfolio of lifting, fixing and anchoring technologies includes the latest and pioneer technology. We aim to supplies the highest quality of precast connection, precast lifting system & accessories that suit every building’s need.

MOMENT Loop Box

The MOMENT Loop Box is available in 3 versions, Single, Double and Multi Version including single, double and multi wire rope loops respectively to ensure strength into the connection.

The Loop Box will need to fixed to the formwork and the flexible folded wires will need to be pulled out to make a connection when ready on site. The load will be transferred from one concrete panel to the other panel via wire rope loop. High strength (1770 MPa) galvanized steel wire rope with 6 mm ɸ will need to be crimped by using compression sleeves / ferrule to form a loop at one end & to transfer a load axially through other end. The load is transferred from one concrete panel to the other panel via wire rope loop.

The key benefits and features for loop box are as per below:

• High strength galvanized wire loop

• Pre-punched nail holes for easy fixing to formwork

• Galvanized steel casing ensuring stability during fixing and concreting

• For construction junction between precast segments

• The loops pop-up automatically ensuring time saving; no rebending is required

• 1770 Mpa wire rope, zinc plated

• Color coded plastic clips

• Ideal for butt junction between wall to wall and wall to column

• Product dimension ideal for logistics and storage

Seamless connection between precast walls

MOMENT Single, Double & Multi Loop Box

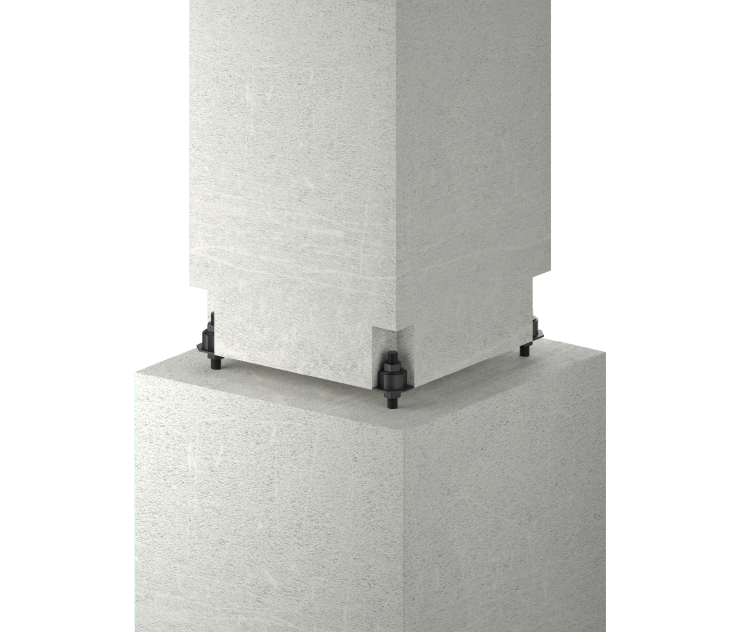

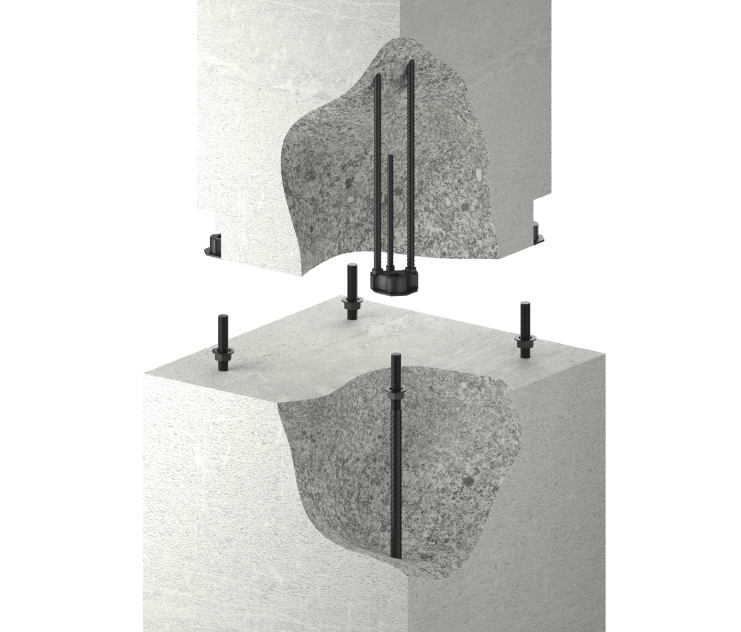

MOMENT MPS-T Precast Shoe

These days, there is a significantly more economical way to assemble precast columns. The Precast Shoe provides a handy solution for connection to foundations or for linking columns together.

The advantage of the pre-fabricated system with screw connection is the quick assembly. The connection is easy to adjust and immediately loadable so that bracing is not required which results in less labor at site and enormous time gain. The system comprises the precast shoe column shoe and the suitable anchor bolts for the foundation base.

The principle: The precast shoes are cast in pre-cast columns, the anchor bolts are cast in foundations on site using a drilling pattern. They are joined by load bearing nuts during assembly. As a last step the bottom of the column and remaining recess are filled with non-shrinking mortar.

MOMENT MPS-T Precast Shoe

Application with precast elements

The Ancon Unilift Systems are engineered and rigorously tested under the strictest quality assurance policy, providing the safest, yet cost competitive solution to the precast concrete and building industry. The Unilift Lifting System includes:

• Lifting anchors

• Lifting clutches

• Recess formers

Cone Anchors

Cone Anchor is made of a round steel rod with a forged foot and head. Forged using special impact resistant steel, the range of Cone Anchor has been specifically engineered to safely lift precast concrete elements in the most challenging of environments and site conditions.

In the same load group, Spherical Head Lifting Anchors are available in different lengths. Longer anchors are installed for reduced edge spacing or for low concrete strengths.

The key benefits and features for Spherical Head Lifting Anchors are as per below:

• Safe, quick, efficient

• Durable clutch is resistant to abrasion

• Huge range of anchors and accessories for all types of precast elements

• 8 load classes from 1.3 to 32.0

• Ideal for beam or wall elements

Anchors are supplied with mild steel finish as standard

Reo (eye) Anchors

These anchors are used with a hanger bar, also known as a tension bar, where the concrete is too weak for a cone anchor. They are ideal for thin panels and other applications where the concrete shear cone developed by the anchor is insufficient to provide the working load limit of the anchor e.g. low strength concrete.

Reo Anchors are used with a hanger bar where the concrete is too weak for a cone anchor

Standard Recess Formers

Recess Formers are used to accurately create the correct recess to accommodate the Locking Klaws during casting, the Recess Former is moulded from a rubber compound exclusively developed to ensure longevity when in contact with concrete.

The outer curved surface of the rubber compound has a hole at its apex to allow the anchor to extend out of the recess former. It is made of highly durable rubber encasing a high tensile steel bolt, complying with many international standards.

The key benefits and features for Recess Formers are as per below:

• Hard oil resistant, yet flexible, rubber

• For attachment to steel and timber forms or floats

• Durable rubber case allows easy and clean removal

Recess former is used to accurately and reliably set the anchor into its recess in the concrete panel

Ancon Unilift Locking Klaw

Besides, the geometry of the Recess Former is unique to each load classification of Locking Klaws, therefore minimizing the risk of errors as the wrong size clutch cannot be attached.

Ancon Unilift Locking Klaw is used for lifting a wide range of precast concrete products for building and civil engineering including panels, pipes, pits, manholes, box culverts, road barriers, bridge beams, planks, sound walls, culverts etc.

The Ancon brand Locking Klaw has been available in the market for many years and is therefore the tried and tested solution for lifting precast concrete elements. We have a wide range of sizes from 1T to 32T which perfectly complements the Spherical Head Lifting Anchor range.

Ancon Locking Klaw helps to safely

rotate civil prefabricated concrete units.

Learn More Here

Looking For High Quality Precast Solutions?

Let Us Drop You A Call For Consultation. For Free.

FRIMEDA Lifting Anchor System

The FRIMEDA Lifting Anchor System consists of flat steel anchors, recess formers and lifting clutches. The design of the lifting clutches and anchors permit loads in any direction. One of the main benefits of this system is the availability of erection anchors for tilting of thin elements with no edge breaking. The clutches can be released either directly by hand at the clutch head or by remote control.

The Anchor

The anchors are made from a special quality of flat steel. The anchor head has a hole in which the locking ring of the clutch can engage.

Ring Clutches

The ring clutch is positioned in the recess surrounding the cast-in anchor and the locking latch is closed by hand, enabling the locking ring to engage with the anchor head. The clutch is thus connected with the anchor in a matter of seconds. The ring clutch can now be pulled in all directions to allow for lifting, rotating and pitching of the unit. There is no preferred direction. To release, open the latch and the ring clutch can be removed.

The key benefits and features for FRIMEDA Lifting Anchor System are as per below:

• 15 load classes from 0.7 to 26.0

• Numerous types of anchor

• Confusion of load classes not possible, because only those components that belong together fit together

• Erection anchors protect the concrete when shear loads are applied

The FRIMEDA lifting anchor system consists of flat steel anchors, recess formers and lifting clutches

A connection of conventional precast elements uses steel wire loops or rebend connections, which require subsequent filling of the connection joints with grout mortar; these types of connections are not immediately loadable to their full capacity. To continue construction, temporary bracing is required to ensure stability of the erected elements until the grout in the joint has cured sufficiently. In many cases considerable waiting periods have to be taken into account in the construction schedule to allow the grout mortar to cure sufficiently.

Dry connection of precast elements dispenses with grout filling the joint, substantially reducing the time and effort required for installation.

The HEK Precast coupler is a boltable precast concrete connection that uses serrated plates, which are immediately capable of longitudinal and shear loads right after installation. Furthermore it compensates for manufacturing and installation tolerances of up to 10 mm.

Advantages:

• Bolt connection

• Durable corrosion protection

• Short installation time

• No temporary bracing required

• Less crane time

• Weather independent installation

• Dismountable

The main advantage of this system is the quick, efficient and weather independent installation of precast elements. The connections can be subjected to their full load capacities immediately after installation. This can accelerate the construction process.

The HEK Precast coupler element, cast into concrete, is both a load transferring and connection element between elements. The precast coupler element with counter plate is designed for a bolt, that is screwed into a fixing anchor cast into the component to be connected.

Learn More Here

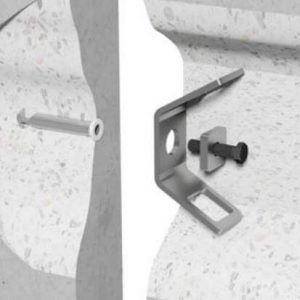

Invisible Connections

Traditionally, precast slabs such as stair landings used to be supported by a steel angle bolted to the wall. Installation was slow, required high degrees of accuracy, tied up the crane with costly hook- time and could only be used on straight walls. The TSS and BSF range of connectors was developed specifically to address these and other needs.

The Architect gains a smooth obstacle-free soffit with no supports on show.

The Engineer gains a robust, simple and efficient connection, which can also be used to satisfy robustness.

The Insitu Contractor does not need to incorporate connections into the wall requiring tight tolerance.

The Precaster keeps control of the connection within the factory, with no need for specialist operations on site.

The Main Contractor gains reduced crane hook-time requirements, and rapid provision of access stairs.

TSS Telescopic Connectors

BSF Telescopic Beam Connectors

For transferring heavy loads from beams into columns, walls or other beams, the ideal solution is the BSF system. These 3-part telescopic connectors have individual capacities ranging from 225 kN to 700 kN. By optionally using BSF connectors in pairs, loads of up to 1400 kN can be catered for.

Learn More Here

Кракен маркетплейс — это одна из самых известных площадок в сети Tor, где безопасность и приватность стали основой взаимодействия. Кракен даркнет пользователи находят удобный интерфейс, систему рейтингов и поддержку Monero, что делает кракен даркнет одной из самых устойчивых платформ для анонимных сделок.