Speeding Up Precast Construction with Hybrid Precast Connection

Project: Woodlands Health Campus

Developer: Ministry of Health Singapore

Contractor: SDK Consortium

Product Supplied: MOMENT Hybrid Precast Connection

Project Description

With 246,000㎡ of the total ground floor area, the Woodlands Health Campus (WHC) which is the first smart hospital in Singapore, consists of an acute hospital, a community hospital, specialist outpatient clinics and a nursing home, connecting the four medical facilities with information and Communication technology.

It is a commonly known fact that precast column connection methods take around an hour to complete, hence crane time is a major cost. Not to mention, temporary propping is also needed for traditional precast column erection which creates additional difficulty of movement. WHC spans over a large surface area, requiring a large number of columns to be erected. Hence, making a choice between a slow-to-erect method or a fast but safe method can have a direct impact on the construction time and costs.

The Solution

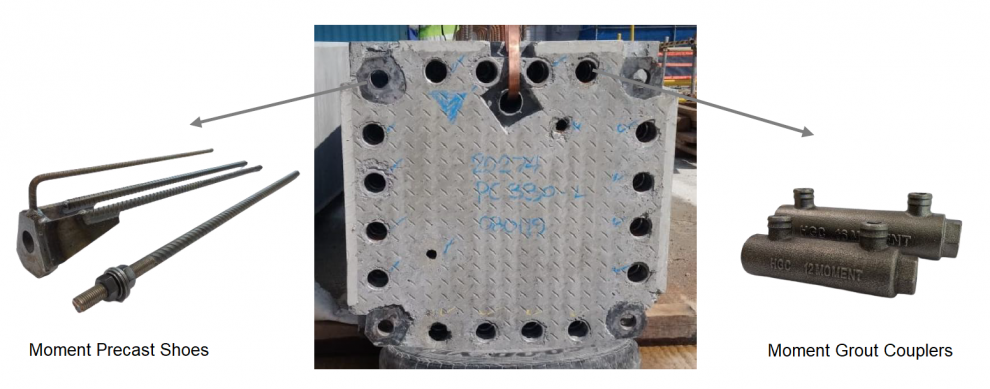

Every minute saved translates into cost savings, therefore we proposed MOMENT Hybrid Precast Connection, the perfect combination of MOMENT Precast Shoe and MOMENT Grout Coupler to connect precast elements.

With this innovative precast connection, we succeeded in securing each precast column in less than 30 minutes. After the installation of MOMENT Precast Shoes, a column is immediately loadbearing with no propping required. Work can continue on the next precast element and then more than one assembly can be grouted, reducing both worker and crane time. The grouting of the column bases has been modified to ensure a speedy and yet effective method, without the need for pressure grouting.

With less worker and crane time, and the absence of props reducing site access, site safety, and storage space were immediately improved.

The Result

Approximately 2000 precast columns were installed using MOMENT Hybrid Precast Connections in this project. We were able to make precast connections 3 to 4 times faster when compared with traditional methods, reducing the assembly time and extending the working space. In summary, it means construction was completed faster but in a safer and more reliable way.

Fill In The Contact Form & Let Us Drop You A Call For A Free Consultation!

Related Articles You May Be Interested

Hybrid Precast Column Connection

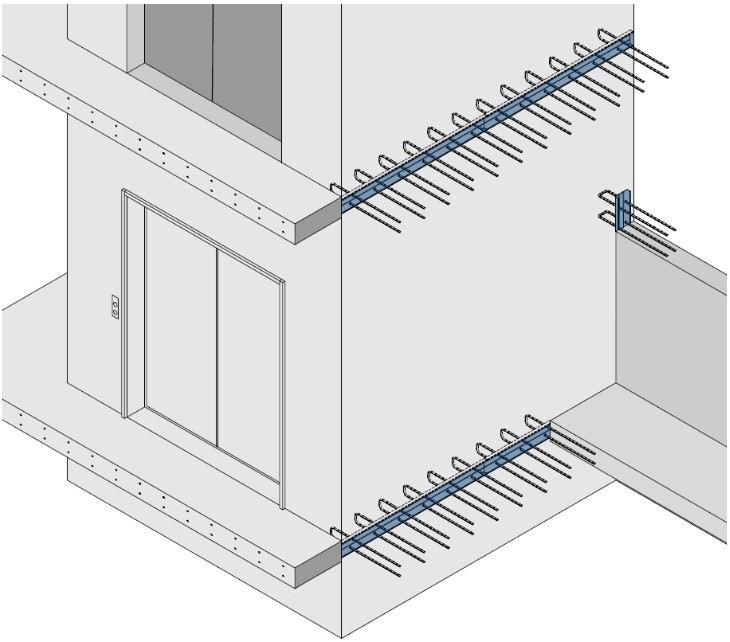

The MOMENT Hybrid Precast Connection is a construction method that combines the use of MOMENT Precast Shoes with MOMENT Grout Couplers to connect precast elements, such as precast column connection and elevator shaft connection. Using these two products in combination offers many advantages over other build techniques, including substantial savings in cost and time, and improvements in site safety. The bolted Precast Shoe connection with its unique ‘dry joint’ feature, makes the connection easier to be adjusted and immediately load bearing so that bracing is not required which results in less labor at site. Grout Couplers offer shorter development lengths (compared to traditional grout tubes), reducing the installation time in the precast factory by reducing the amount of confinement steel and enabling connections in much thinner elements. • Cost savings over other similar jointing methods To improve our clients’ productivity on site, MOMENT Hybrid Precast Connections have been applied in a few prominent projects in Singapore. Woodlands Health Campus, Singapore National Skin Centre, Singapore Air Trunk, Singapore Download Our Brochure For More Information Related Articles You May Be Interested Related Products You May Be Interested

MOMENT Precast Shoes

MOMENT Half and Full Grout Couplers

Benefits of MOMENT Hybrid Precast Connection

• Quick installation in the precast yard and on site

• Immediate load bearing before grouting

• No propping required on site

• Improved site safety and access

• Resists seismic loadsOur Project Reference

Connect Precast Elements The Efficient Way.

Let Us Drop You A Call For Consultation. For Free.

We are Leviat. We are Ready.

From 9th November 2020, we will communicate with you as Leviat.

Exciting changes have taken place in our business that enable us to provide you with an enhanced product and service offering, and strengthen our ability to meet your evolving needs in the future.

Read on to find out more.

We are Leviat

Leviat unites the expertise, skills and resources of CRH’s construction accessories companies in a single global organisation.

Leading industry names, including Ancon, HALFEN, Moment and Plaka, have come together as Leviat to better support our customers. We are building on our individual strengths to enable us to be even more agile and responsive to your needs, as they evolve over time.

The world is changing. Whatever the future demands of our industry and the world around us….We are ready.

Our Product Brands & Technical Support Services

Leviat is the home of Ancon, HALFEN, Moment, Plaka and many more trusted product brands.

Halfen Moment has transitioned to a product brand within Leviat’s comprehensive product portfolio. This means the branded products you know and trust, such as Moment rebar couplers, Moment precast lifting system and Moment post tensioning system etc are all still available from us, and with even greater company resources behind them, these products will continue to be developed and improved.

Furthermore, as Leviat, we will continue to provide the first-class technical design assistance that you value from us at every stage of a project, from initial planning to installation and beyond.

Our Global Resources & Local Support

Leviat comprises almost 3,000 people at 60 locations worldwide.

Now, every promise we make locally to our customers has the commitment and dedication of this global team behind it.

This is what you can expect from Leviat:

- Leveraging our global engineering resources and manufacturing footprint will enhance our services locally, by making us more flexible and responsive

- Combining our extensive technical expertise and market knowledge, and coordinating all our research and development activities, will allow us to innovate faster and more effectively

- Dedicated digital engineering resources and investment will accelerate our design and service capabilities, and help us to better support your business

Any Questions?

We look forward to continuing to work with you as Leviat, and supporting your business in the years ahead.

If you have any questions about our evolution to Leviat, please do not hesitate to contact any member of the team or visit Leviat.com.

Imagine. Model. Make.

CARES Certified MOMENT Mechanical Splicing System

Leviat is proud to receive quality recognition of the MOMENT JoinTec Coupler system by the grant of approval in accordance with CARES Appendix TA1-F.

CARES is an independent, not-for-profit certification body that operates for the benefit of the construction industry, offering certification schemes for companies that produce materials or components for the reinforced concrete industry.

Download our CARES certification here.

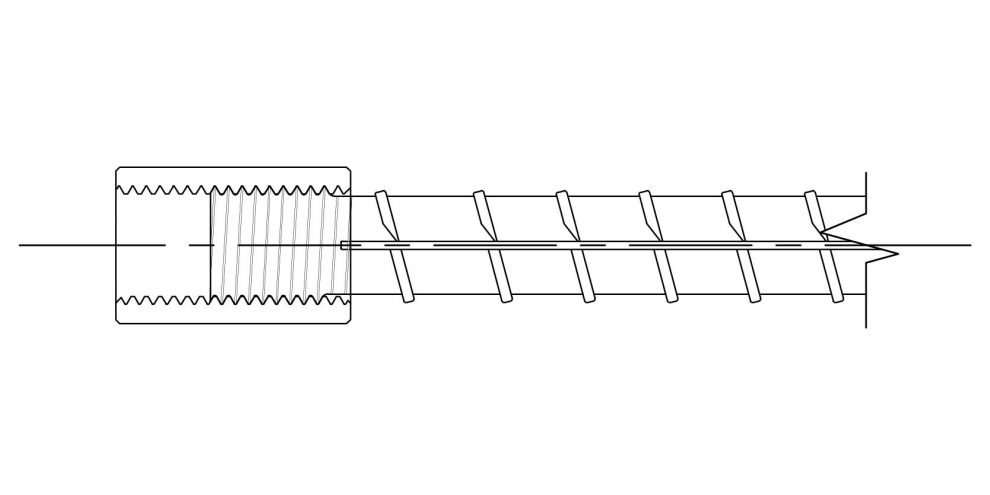

MOMENT JoinTec Connection

MOMENT JoinTec mechanical connections conform fully with applicable codes, including BS 8110 Pt 1:1997 Clause 3.12.8.16.2 Bar in Tension and ISO 15835-1:2009. The MOMENT Jointec coupler system provides a ‘Bar Break’ solution with defined ductile behaviour, allowing the connection to perform like a continuous reinforcing bar.

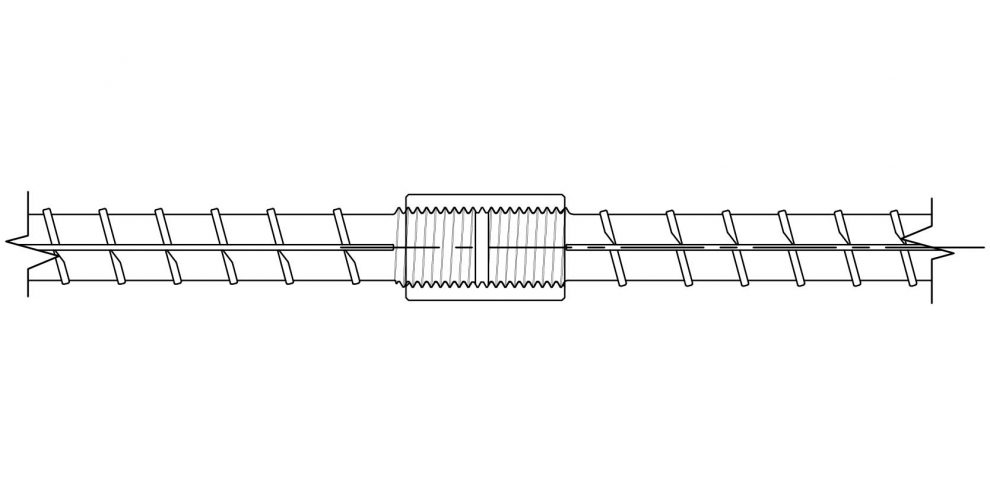

Fig 1 – MOMENT JoinTec Mechanical Connection provides a ‘Bar Break’ solution as it performs in excess of the ultimate strength of the rebar.

Fig 2 – MOMENT JoinTec mechanical connections perform beyond the yield point of the bar whereas Lap Splices are only defined in the elastic area. This indicates that the MOMENT JoinTec connection, which work as continuous bars, provides additional strength and safety all-round, independent of the quality of the surrounding concrete.

Design Codes & Specifications

In reinforced concrete design, the Structural Engineer is faced with the task of determining where and how reinforcing bars must be spliced in a structure. This must be done to ensure that the national regulations are adhered to and also to make sure that the structure will not suffer a progressive collapse if overloaded.

Design requirements of the applicable codes, BS 8110 and EN 1992-1 generally assume a minimum connection strength but are silent on the details about test methods and conformity assessment. ISO 15835, which is used as the basis for the CARES approval scheme covers all aspects of coupler production and assessment including:

- To assess the serviceability, a test is made on a representative gauge length assembly comprising reinforcement of the size, grade and profile to be used and a coupler of the precise type to be used, the permanent elongation after loading to 0.6 fy should not exceed 0.10mm.

- It also covers tests for couplers to be used for mechanical splices in reinforced concrete structures under predominantly static loads and additional requirements for couplers to be used in structures subjected to high cycle elastic fatigue loading and/or too low cycle elastic-plastic reverse loading to represent seismic activities.

As most of the Southeast Asian countries progress in nation-building, federal governance, regulations and codes are becoming more stringent, MOMENT JoinTec connections, the proven mechanical splice method, provides you with the ability to design and build concrete structures to withstand the test of time.

MOMENT JoinTec Couplers were used extensively for reinforcement bars within the railway in MRT projects.

Recognized by:

Related Articles You May Be Interested

Managing COVID-19 Stress

COVID-19 has taken over the world in the most unexpected ways. Everyone all around the world is battling with this invisible enemy in their own ways. However, some proven steps that we may follow include staying at home, keep your distances and maintain your hygiene. Here are some examples of how you can maintain positive in order to make this challenging period a little lighter physically and emotionally.

1. Balance Social Media Consumption

Social media is the place to be among others. You are bound to receive updates on the pandemic locally or globally – but there is too much negativity surrounding it too. Try to balance out your social media intake by not taking your phone to bed or limit screen time – there’s an app for this too. 😉

2. Take Care Of Your Body

This is the biggest silver lining in this whole situation. We often neglect our self-care on a day-to-day basis due to our busy schedule. In this situation, we are free to redefine our work-life balance and reorganize all our pending workout routines restricted by traveling to and from office.

3. Connect With Others

We are all in this together believe it or not. Some of us are blessed to be stuck at home with friends and/or family but some are not. Check with your friends/family who is living alone. Initiate conversation or call in once in a while. It’s best to get and offer help where necessary.

4. Focus On Small Things

You might not realize this before, now you know small things can bring you happiness too. Don’t know where to start? You can start by asking yourself these few questions:

- What made you feel grateful?

- What praise and/or feedback did you receive?

- What experience gives you pleasure?

5. Build Resilience. Hard Times = Growth

This is the most common success factor every successful people will tell you – hard times will help you grow. This confusing time is difficult for everyone but almost always there’s a result in growth that shapes you to become a better colleague, friend, family or human being per se. You will always grow and this time it might be in an unexpected way.

6. Get Dreaming. Plan Your Next Adventure

Just because the world is on halt, does not mean your imagination and plans should have too. This is the time to plan your next big adventure – domestically or internationally. If you can dream it, you can do it!

So, have you done any of these in the last few months? Would you like to explore this on top of your routine? Let us stay positive and stay safe, together!

How To Maintain Reinforcement Continuity At Concrete Joints?

The concept and use of reinforcement continuity strip systems or ‘pull-out bar’ systems have been widespread in Asia & Europe over the last 30 years and is widely accepted means of providing reinforcement continuity across construction joints in concrete. The system utilizes the concept of overlapping reinforcement to provide a connection.

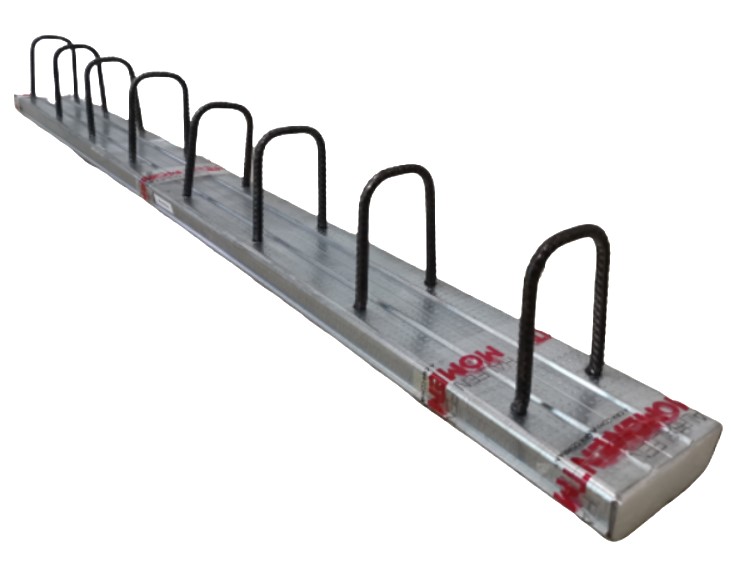

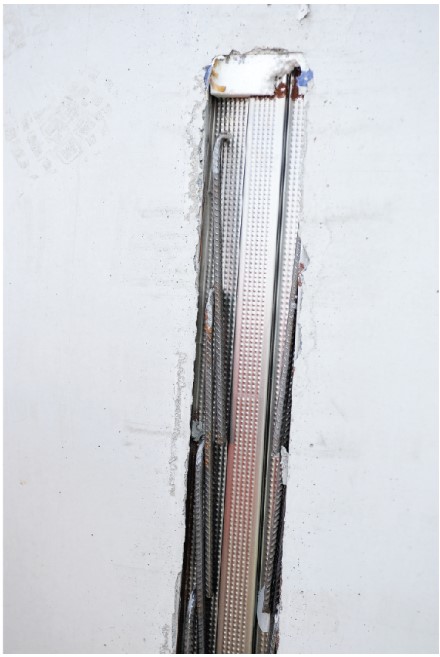

The MOMENT Bar Box system consists of specially selected, high yield reinforcing steel, housed in a galvanized steel casing with ribbed surface to provide an effective concrete bond. The end of the unit is sealed with a polystyrene block in order to prevent the ingress of concrete.

The Bar Box reinforcement continuity is manufactured using a reinforcing bar that meets the requirements of the local reinforcing bar standard.

Why Use MOMENT Bar Box?

The product design ensures fast and easy fixing by nailing to the formwork. Alternatively, it can be wired back to the main reinforcement cage. The concrete is then cast. After removing the formwork. The cover is removed and the bars are quickly straightened using the specifically designed rebend tool. The steel casing remains embedded in the wall and is filled with concrete when the next section is poured, the dimpled surface providing an efficient key.

When compared to traditional joint construction methods, the product offers a cost-saving by means of a less labour intensive installation process and simplification of formwork with the removal of the need to drill shuttering. This contributes to the acceleration of the construction process. As the bars remain enclosed within the casing until required, they are protected and the risk of injury from projecting bars is minimized. Easy to use, the system requires little onsite training in order to carry out the installation.

Most joints in concrete, on many different types of construction sites, have the potential to be formed using MOMENT Bar Box. It has been supplied to high rise commercial buildings, water treatment plants, hospitals, prisons, energy from waste facilities and many more types of construction sites.

Typical Joint Application

- Floor slabs

- Walls

- Stairwells

- Corbels

- Diaphragm walls

- Jumpforms

- Brick support ledges

Maintain Robustness Of Your Concrete Joints

Let Us Drop You A Call For Consultation. For Free.

How to Install MOMENT Bar Box?

Step 1

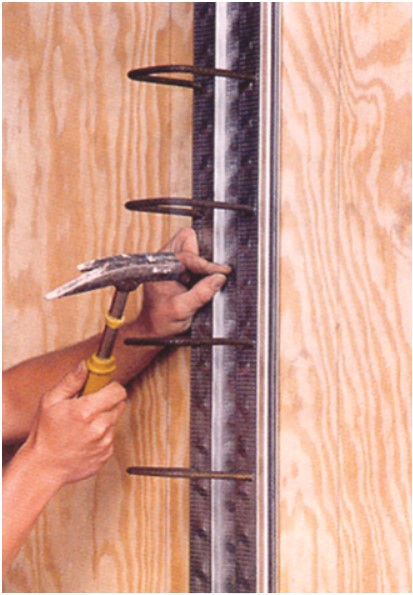

A MOMENT Bar Box unit is installed by firstly nailing through the casing to the shutter face. The casing is annealed at points to make this operation easier.

Step 2

With the Bar Box unit securely in place, concrete can be poured and the entire unit will become part of the first pour of the concrete and structure.

Step 3

With the formwork struck, the Bar Box lid and end caps can now be removed and discarded. The lap bars contained inside the case will now be revealed for rebending.

Step 4

Check the stirrups are completely clean.

Step 5

With the Bar Box casing opened, the lap bars can be bent out using the correct tool according to our installation guidelines.

Related Articles You May Be Interested

Our Measures in Response to the Movement Control Order

Dear Client and Business Partners,

In recent days, COVID-19 has dominated our thoughts and conversations. We at Halfen Moment will do our part to prevent the spread of transmission and take care of our customers, co-workers and communities. Following the recently declared Movement Control Order to be imposed in Malaysia, India and Philippines, the management of Halfen Moment has implemented work from home arrangements for our colleagues from these entities during this period.

The arrangement is aimed at ensuring colleague safety while also retaining adequate capability to continue servicing client needs. Our colleagues working from home remain contactable via both email and mobile, and can also conduct meetings via video and teleconferencing facilities. This enables us to maintain the high level of quality and consistency that you have come to expect from Halfen Moment. While all efforts are focused on maintaining business as usual, we seek your understanding and patience should there be unexpected delays arising from disruptions in the supply and service chain.

Halfen Moment Team has always been guided by our core values of:

Make It Happen

Ownership

Maintain A Smile

Embrace Change

Never Compromise

Teamwork

Hence, we will continue to pursue these values as we continue to single mindedly focus on serving you to the very best of our abilities, despite the challenging weeks and months ahead.

Please reach out to our Halfen Moment representatives if you have any questions or concerns, or call/whatsapp our Hotlines at +6012-5249956 or +6012-5539956, or email us at info@halfen-moment.com, or even live chat with us on our website from 9am-6pm MYT.

Lastly, on behalf of Halfen Moment Group, please stay safe and stay healthy.

Rob Van Haaren

Managing Director

Halfen Moment Group

Precast Lifting’s Dos & Don’ts For Safety & Productivity

2 of the most challenging aspects of constructing with precast concrete are the lifting/handling and connections. In this section, we will deal with the dos and don’ts of lifting, moving and handling of precast concrete elements with regard to safety, productivity and cost-effectiveness.

This article will not cover topics such as installation or troubleshooting as those topics are already covered quite comprehensively by the individual suppliers in their literature. Instead, we will focus on the bigger picture issues that are preventing the industry from moving forward.

Traditional Methods

Still to this day, reinforcement U Bars and Post Tension Wires are still used as lifting points for precast concrete elements, but those using these types of lifting points do not understand the dangers that they are exposing the workers to. Most lifting designs do not have any built-in redundancy, so a failed lifting point will most often result in an element crashing down to the ground. Even if there are no casualties, a dropped element is often then scrapped as the damage resulting in a dropped element is too much to repair them.

The cost of using a proprietary lifting anchor is approx. 0.5% of the cost of a typical element and therefore can be considered as very cheap insurance against losing a piece of precast concrete. Not to mentions all the likely liquidated damages that could be incurred as a result.

The reason why rebars and post-tension wire are not suitable as lifting points is simply due to the fact that they are not designed for it. Both steels are designed to work in tension and although rebars can be bent, the ductility of the steel is always reduced after the bar is bent due to yielding in the extreme fibres of the steel. So much so, that there are discrete limits on the size of the radius that you are allowed to bend them to. Generally between 4d to 6d depending on the code and the diameter of the bar. Attaching a crane hook to a U Bar will result in the partially yielded bar to be further bent around a radius that is even small than those allowed in the rebar codes. Therefore the risk of failure increases significantly using either rebar or post-tensioning wire.

There are some proprietary lifting systems available in the market that seem to call this suitability in to question but to understand it fully, you need to cut through the wire and look at the cross-section. The wire products sold for lifting have a 7 strand configuration, but the central core strand is made of a fibre core and not a steel core in the case of a post-tension wire. This allows the wire to be much more flexible and bend around a smaller radius than its steel-cored cousin.

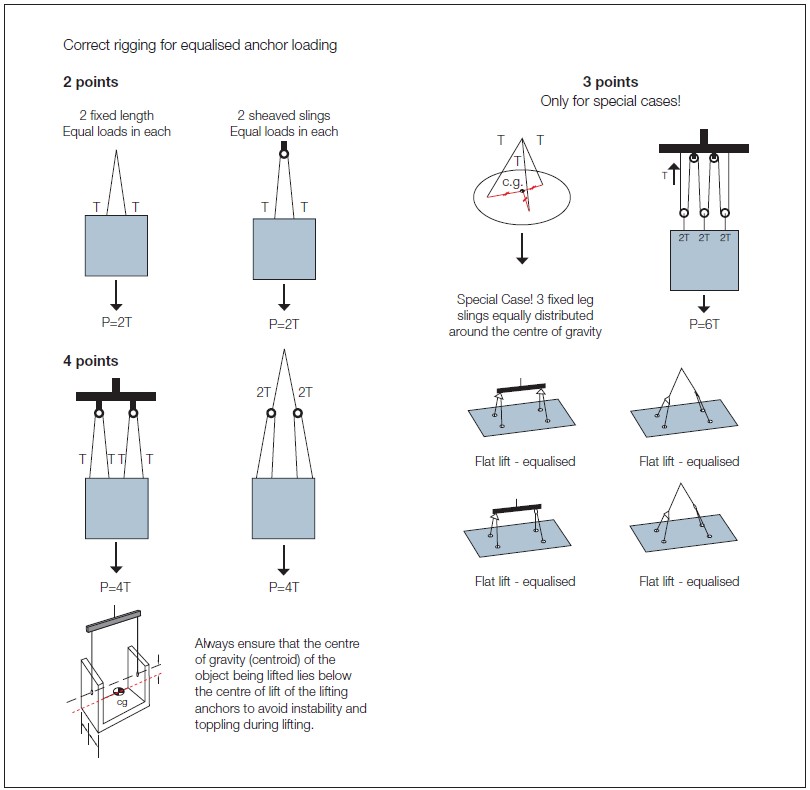

2D Lifting

There are 2 very common ways of lifting 2-dimensional panels, namely, face lifting and edge lifting.

Face lifting is where a number of anchors are placed into the flat top of an element and the concrete is lifted in a flat position. This is commonly used for staircase landings, man-hole covers and floor units.

Edge lifting is where a number of anchors are placed along the thin edge of an element so that the concrete can be tilted up into a vertical position for storage and installation. This type is commonly used for shear walls, infill walls and façade panels.

The challenge with lifting and handling all precast components is the rigging required to attach the element to the crane but still allowing for the load to be equalised across all the anchors. Some real no-no’s for this would be if fixed-length chains or slings are used, or if you try and use a multiple of 3 anchors in any one lift, so 3, 6 and 9 anchors should only be used if absolutely necessary or with very advanced rigging to ensure the anchors are fully equalised.

Never Compromise On Safety! Let Us Drop You A Call For Consultation. For Free.

3D Lifting

As we have moved towards PPVCs and PBUs the challenges associated with lifting have changed and in many ways become much more complex.

Often the element being lifted have a number of boundary conditions that we need to respect such as wall thickness, concrete weight and centre of gravity.

One of the biggest challenges associated with the lifting of these 3-dimensional elements is the weight of the element due to the availability and range of cranes available on site. There are a number of precasters exploring lightweight aggregates or the use of fibre reinforcement to reduce the weight of the elements, but many prefer to simply use thinner and thinner walls. The industry seems to be settling on a 90mm thickness for a PPVC wall, so back to back elements can provide a 200mm thick finished wall by backfilling the remaining 20mm with a cementitious grout.

The wall thickness will often mean that we need to use a lot more of a smaller capacity anchor rather than just a few larger capacity anchors. This, in turn, makes the equalisation of the loads even more challenging and most precasters prefer to use fabricated lifting frames to assist with the equalisation.

However, as most architects prefer to have a few different geometries in their buildings, it means that one standard lifting frame gets used for a variety of different geometries. Providing the frame is well designed, this can be a good way of minimalizing the capital outlay for a project, but excessive out of plane lifting should be avoided at all costs as this can result in the thin concrete wall spalling away and causing damage to the concrete or, worse still, a failure of the lifting point. Therefore the lifting frame should be designed to be as closely aligned to the wall geometry as possible.

Another challenge for 3-dimensional shapes that needs to be considered is the relative position of the anchors to the centre of gravity (COG). Providing the centroid of all the lifting points coincides with the COG when viewed in plan, then the element will be lifted flat with no tilting. However, as each PPVC might be slightly different, it is not practical to do this 100% of the time and some slight lifting or rotation is deemed to be acceptable.

One thing to be avoided wherever is that the centroid of lifting is lower than the COG. There are a number of exceptions to this, but in general, the element will be much more unstable than it would be if the centroid of lifting was above the COG.

Lifting In Thin Elements

The thin walls do create a challenge for lifting as you are required to place lifting anchors together with any required supplementary rebar (an additional bar near to, but not in direct contact with the lifting anchor) or complementary rebar (additional bar in direct contact with, or passing through the lifting anchor) into a very think section whilst respecting concrete cover and avoiding the mesh.

For Singapore, using supplementary rebars is not favoured by professional engineers, with most of them preferring to use anchors with complementary rebar, but the problem of placement still exists. According to SS EN 1992-1-1 the covered required to ensure bond transfer is just 1x bar diameter, so we only need a cover of 13 or 16mm depending on the capacity of the anchor being used. This makes it easier to fit inside the wall and transfer the lifting stresses into the concrete via bond transfer using the development lengths defined in SS EN 1992-1-1 Clause 8.4. One common trait that has been adopted by some professional engineers and needs to be stopped is the insistence on the complementary bars being the full height of the PPVC and returned under the slab at the base. This consumes an additional 7m+ of steel per lifting anchor which results in unnecessary and additional cost and additional embodied CO2 into the element which is bad for the bank balance and the environment. For a PPVC with 8 lifting points is results in about 90kgs of additional material with a cost of more than $70 per element that could be eliminated.

Health & Safety

The final, but the most important, piece of the puzzle is health and safety. At the moment, their elements are placed into position using a crane and then we need operators to climb up to the top of the element (3m+) just to disconnect the clutches and hooks. There are a number of remote release systems available on the market that contractors and precasters alike could consider and significantly improve the productivity and safety of precast operations on site.

Related Articles You May Be Interested

Never Make Safety Vulnerable For Any Reasons

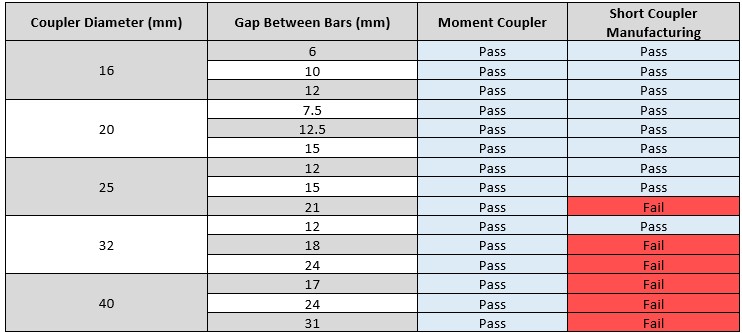

An alarming change to common practices in coupler length are sweeping across India.

Couplers, or Mechanical Splices as are they are also called, are becoming a common method for connecting reinforcing bars together. However, from what we can tell, the way that couplers work is still greatly misunderstood by the vast majority of the Structural Engineering Industry. Therefore, the majority of Structural Engineers happily take the lead of the various standards organisations around the world who have written standards to empirically determine the performance of a system, but this has led to 2 key problems that jeopardizes the structural integrity of our concrete structures.

1. The samples are prepared by the supplier of the system and are usually prepared and installed perfectly. For obvious reasons, this perfect installation is not always possible on site due to manufacturing tolerances and site conditions.

2. The global standards and certification bodies that exist today, are mainly focussed on the initial proof of concept of a system rather than the on-going quality control. Even those bodies that have some element of on-going quality control do not simulate the on-site conditions.

In short, there is no “policing” of the quality control at site level.

For these reasons, most certified suppliers build in some additional robustness to allow for the issues that commonly occur on site, namely:

1. Imperfect thread lengths. There is a tolerance on the thread length that can easily result in the engagement of the 2 bars being 45% : 55% instead of the tested 50% : 50%.

2. Gaps between the rebars. In the case of prefabricated pile cages, it is impossible to have all the bars in exactly the same plane and as such a gap of up to 20mm between 2 bars could easily occur, again reducing the engagement of the thread.

As you can see, both of these will result in the same issue, that the engagement of the thread on the end of the rebar into the coupler will be compromised and a smaller engagement will occur. Thread length is defined to ensure that the amount of load transferred to each thread does not exceed the stripping capacity of that thread. If the stripping capacity is exceeded, then the failure mechanism will change to a stripping failure.

We therefore need to provide a sufficient safety factor against this that will also cover the typical onsite issues shown above.

In India, we have seen an alarming trend where people are marketing a “2D” coupler system where the length of the coupler has been reduced by about 20% to 2x bar diameter. It does pass all the necessary tests in the standard but does not perform well when you try to mimic the onsite problems listed above. We are sure it is only a matter of time before similar products appear in other countries as people strive for cost reduction, but we need to be aware that in this case, cost reduction is directly reducing the safety of the system.

We understand these issues and recently conducted some comparative tests and found that the 2D coupler strips with a bar gap of only 15mm, whereas the longer standard coupler that is marketed by certified suppliers continues to work properly well beyond this limit. This means that the total safety factor on the “2D” coupler is less than 20% even if the installation is performed perfectly.

Never Compromise On Safety!

Let Us Drop You A Call For Consultation. For Free.

Impact Of Coupler Strength With Reduced Embedment

- Gaps between the bars of greater than 15mm fail with the shorter coupler, but still pass with the Moment coupler.

- 40mm coupler with a reduced engagement of just 19% will result in a failure using the shorter coupler.

- There is no factor of safety against failure of typical installation issues.

We should not be comfortable with this reduction in total structural safety and strongly urge structural engineers to investigate these topics more thoroughly and ensure the future robustness of our built environment for future generations.

Related Articles You May Be Interested

3 Ways To Connect Precast Concrete Wall To Foundation Effortlessly

When considering the best options for your building project, the benefits of going with a concrete wall panel system are many. By choosing a concrete wall panel system, these features may provide advantages that can be enjoyed by owners, architects, engineers and contractors on site. The benefits include:

- Energy efficiency

- Environmental reliability

- Aesthetically attractive

- Minimal preservation

- Speediness of construction

- Onsite Productivity

To enjoy the benefits, we must make sure the connection between the precast elements and of the precast walls to foundation is robust enough to ensure the safety and integrity of the structure. Here are 3 main ways to connect precast wall panels to foundation.

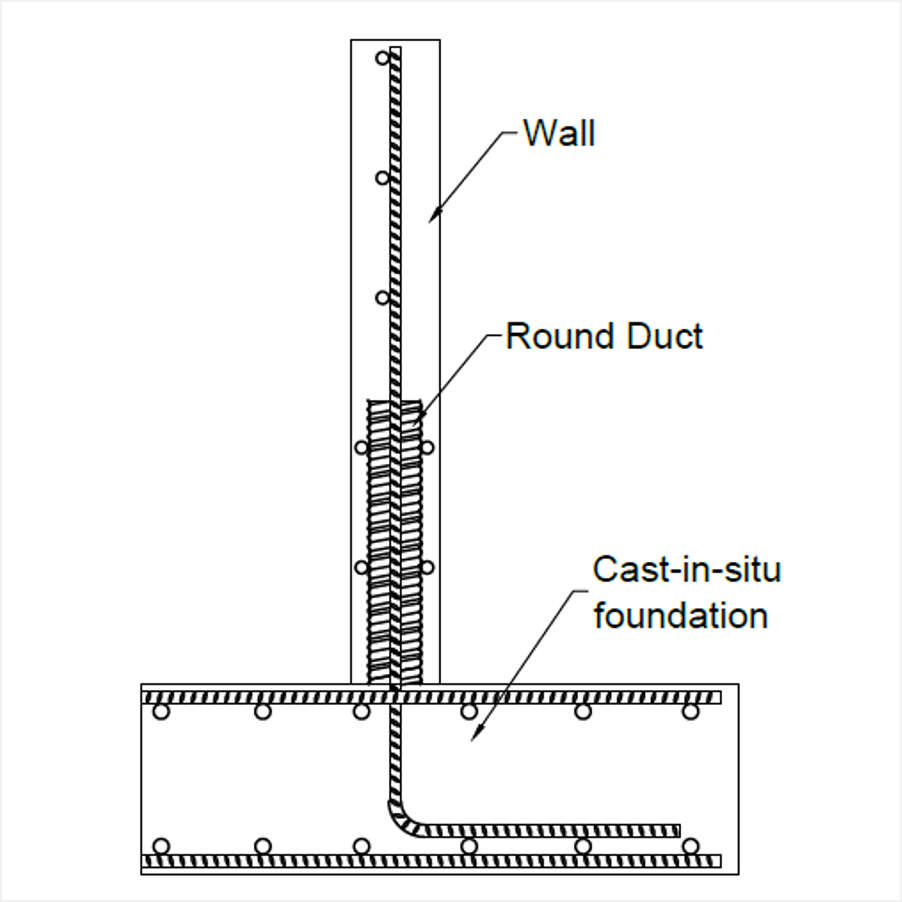

Corrugated Duct

Casting Corrugated Duct into the precast element is the traditional method to connect precast walls to foundation. Corrugated duct is used as a hole former for a variety of precast and cast-in-situ concrete works. The hot dipped galvanized metal duct is strong and durable for casting into precast walls and then to be connected with rebars from the foundation.

Although duct has been a commonly used method for precast connections, one of the major disadvantages of duct application is the huge amount of grout needed to fill up the duct in order to secure the connection between the precast wall and foundation.

Eventually, this traditional method will increase the cost and time of the overall construction.

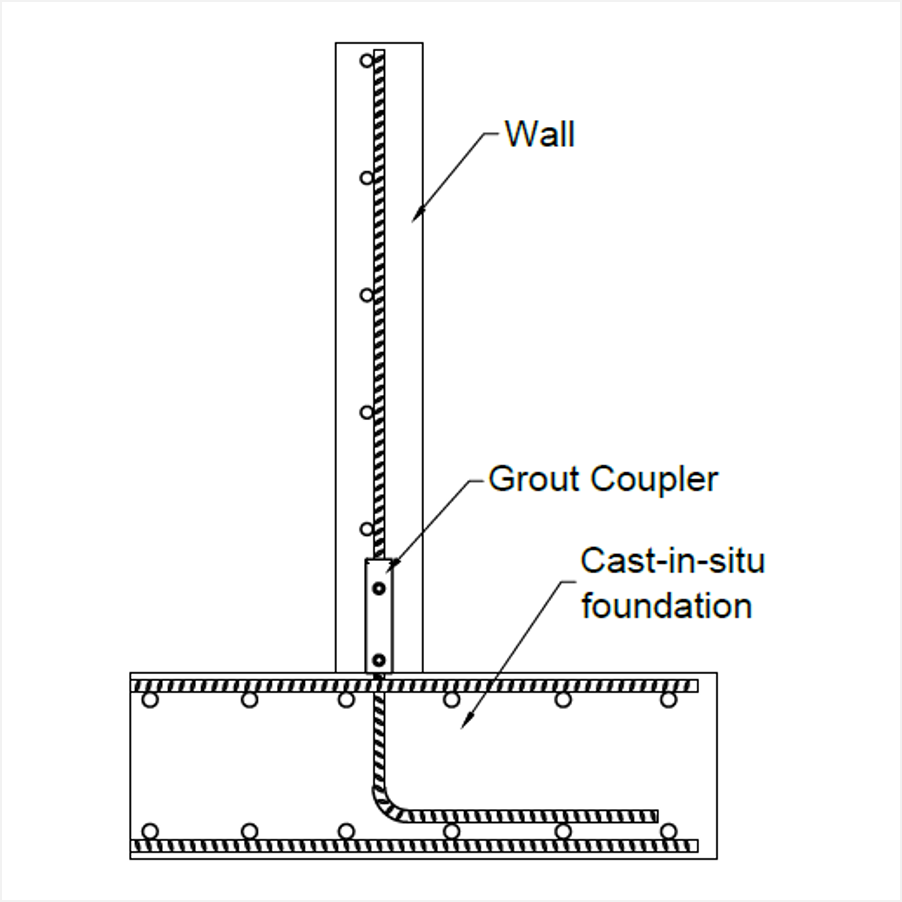

Grout Coupler

Specifically for precast connections, Grout Coupler can be used for connecting precast walls, columns, beams either horizontally or vertically. The most popular connections used with Grout Coupler are:

- Precast concrete column to foundation connection

- Precast column to column connection

- Precast beam to column connection

- Precast wall to foundation connection

- Precast wall to wall connection

The rebars protruding from the foundation are simply inserted into the grout coupler, which has been casted in the precast wall. When pumped with MOMENT’s proprietary 100MPa grout, the grout coupler system is a bar break technology and is capable of carrying very high bar loads regardless of the rib profile on the reinforcing bar.

Although this is not the most popular application of grout coupler but the application of grout coupler for precast wall to foundation is still widely accepted in the market.

Precast Shoe

Mainly used for connecting precast column and foundation, Precast Shoe can also be used to connect precast wall panel to foundation. They are especially suitable for anchoring in flat structures such as the foundations or walls that have sufficiently large edge distance.

The advantage of this precast system with screw connection is the quick assembly. The connection is easy to adjust with a healthy tolerance and immediately loadable so that bracing is not required which results in less labour at site. However, they are not specifically designed for walls and therefore have a limitation on the wall thickness and thin walls cannot be connected using this type of product.

The system comprises of the precast shoe (cast into the precast wall) and the suitable anchor bolts (cast into the foundation) for the foundation base. Both elements are joined by load bearing nuts during assembly on site.