Leviat introduces the revolutionary new MPS-T Precast Shoe

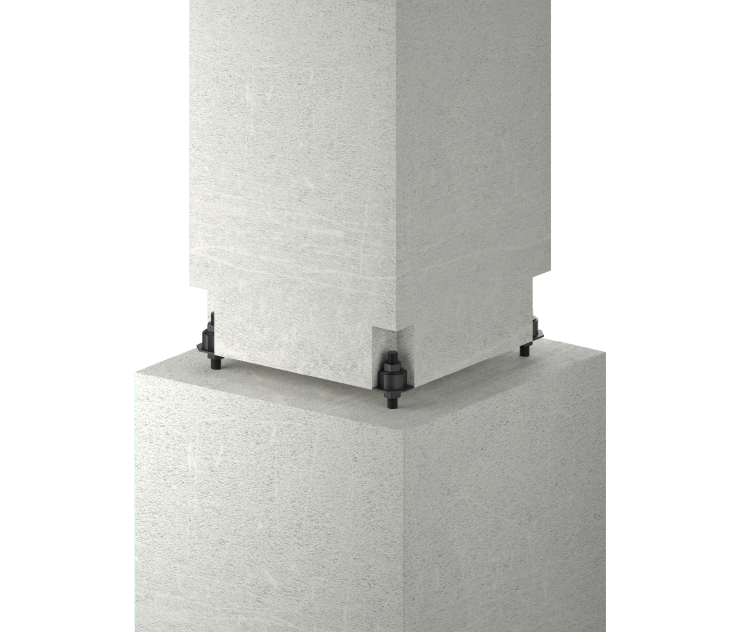

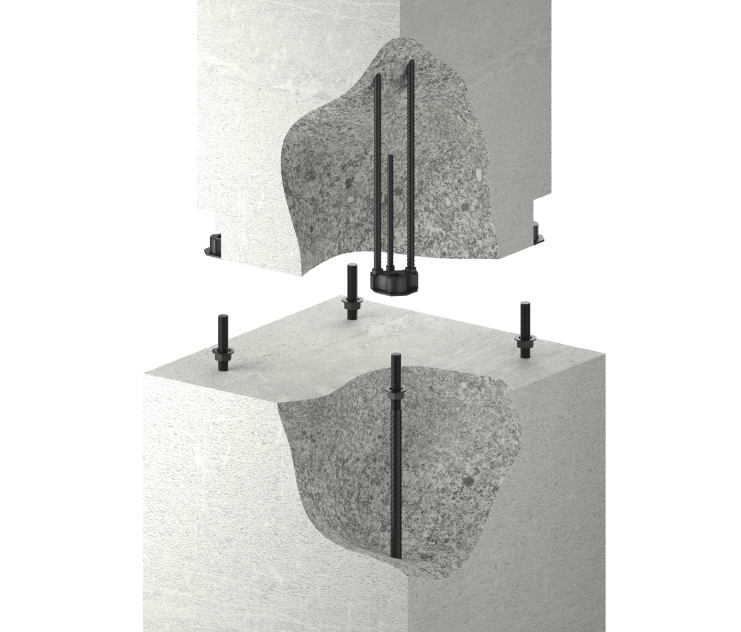

Leviat revolutionized the existing MOMENT Precast Shoe with the latest innovation of MPS-T Precast Shoe. The improved Precast Shoe has been reengineered for improved performance and features a sleek metal base plate that resists calculated loads.

The metal base plate of the MOMENT MPS-T Precast Shoe has a detachable compression bar and a tension bar. This innovative feature allows the precast shoe to be easily assembled and disassembled, reducing the amount of storage space necessary and simplifying site installation. This improves the rebar-to-baseplate connection quality, lowers welding costs, reduces the danger of poor welding quality, and improves site safety. Furthermore, this connection type allows for a more precise quality check.

June Ng, Sales Director of Leviat in Southeast Asia said

“Leviat is continually striving to improve its solutions in order to better satisfy the needs of its clients. We developed the MOMENT MPS-T Precast Shoe in response to the client’s feedback, which benefits users from all areas of the construction industry, including consultants, designers, precasters and contractors, in terms of design, installation, and storage. The new Precast Shoe is part of Leviat’s continual drive towards innovation with products that improve performance to help create better buildings.”

Learn more about MOMENT MPS-T Precast Shoe here.

Celebrating 30 Years Of MOMENT

Leviat is proud to be celebrating the 30th anniversary of the MOMENT brand.

Begun in 1991, the MOMENT building products are now in 20 countries in Asia. Thanks to the close collaboration between our engineers, customers, business partners and local institutions, MOMENT products continue to revolutionise construction processes in Asia.

The last 30 years have been filled with a lot of growth and transformation. As Leviat, we are more agile and responsive to evolving customer needs, helping our ambitious construction partners to turn architectural visions into reality and build better, safer, stronger and faster.

Watch the video above as Rob van Haaren, the Country Director of South East Asia & India congratulates the Leviat team behind the MOMENT brand.

Leviat was formed in 2020 when CRH construction accessories companies came together as a single global organisation. It is the home of Moment, Halfen, Ancon, Plaka and other trusted product brands. Learn more here: www.leviat.com.

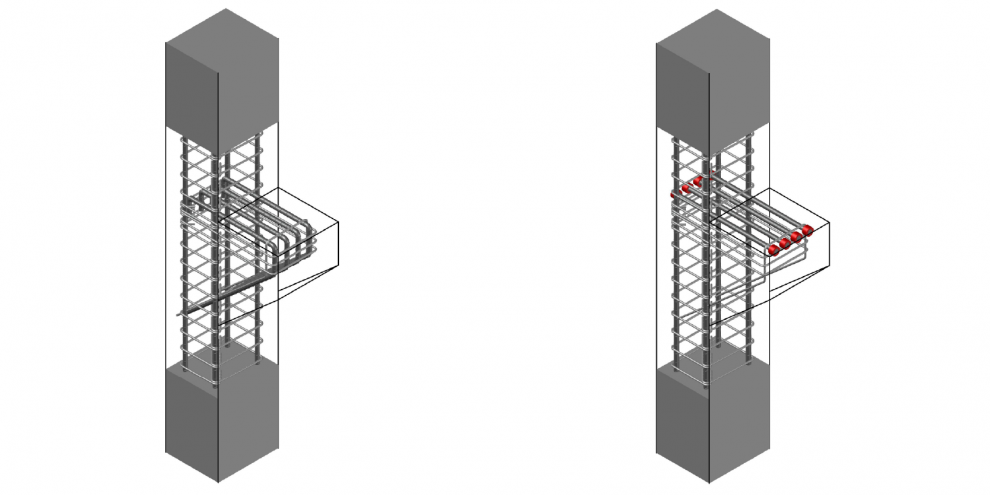

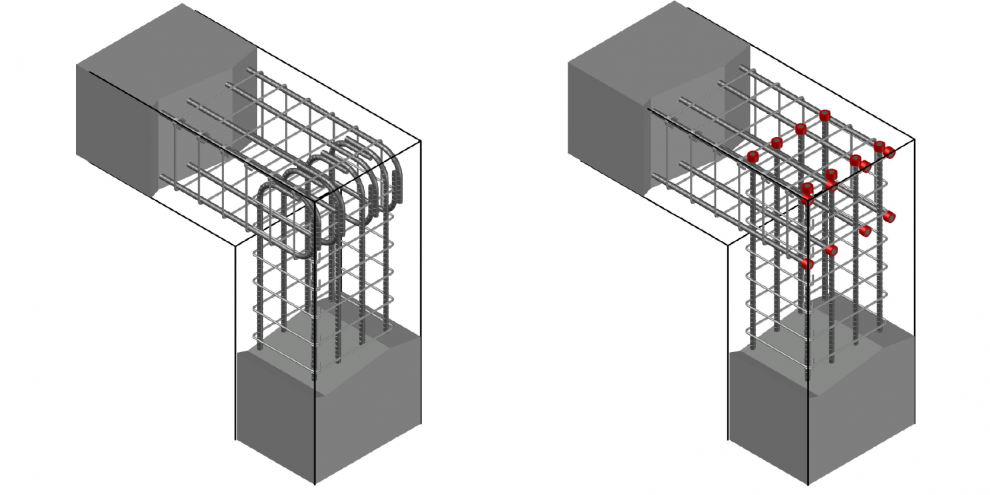

The Alternative To Hooked Rebars

Whether you are trying to tie pile cages into capping beams or curtail reinforcing bars at the end of beams, heavy congestion or other constraints can often mean that bending or placement of bars is impossible, or at the very least, incredibly time-consuming.

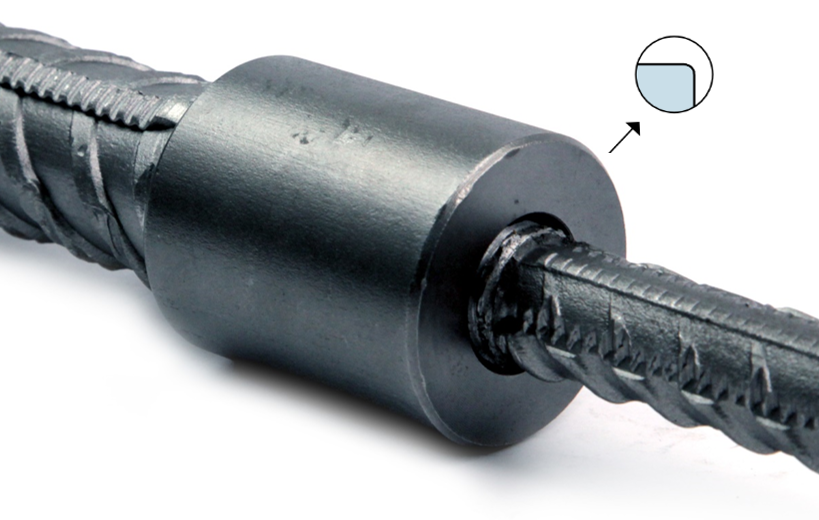

Terminator Coupler is a simple and effective alternative to hooked rebars. It is secured to the end of the rebar, creating an anchorage within the concrete. The assembly of the rebar and the anchor provides an anchorage that is superior to long or bent rebars.

Being the replacement method of the conventional hooked rebar, the Terminator Coupler reduces the problems of rebar congestion in heavily reinforced compact concrete in the anchorage zones, which ultimately eases the compaction process, leading to a better concrete quality in key areas of the structure.

The front face of the coupler is generously designed to carry the full tension load of the rebar when the anchor is bearing against the concrete or structural steel.

For Designers

Terminator Couplers allow reducing steel congestion and steel to concrete ratios. They offer overall better buildability by making possible installation of anchors after the positioning of the rebar.

For Contractors

Terminator Couplers offer a fast, compact and easy-to-install alternative to hook bar, especially on large diameter reinforcement. Concrete flow is also favourably impacted. Rebar preparation can be outsourced or performed ahead of the installation without slowing down the operation.

For Cut & Bend Fabricators

Terminator Couplers are fully compatible with our JoinTec threading system.

Applications

Related Articles You May Be Interested

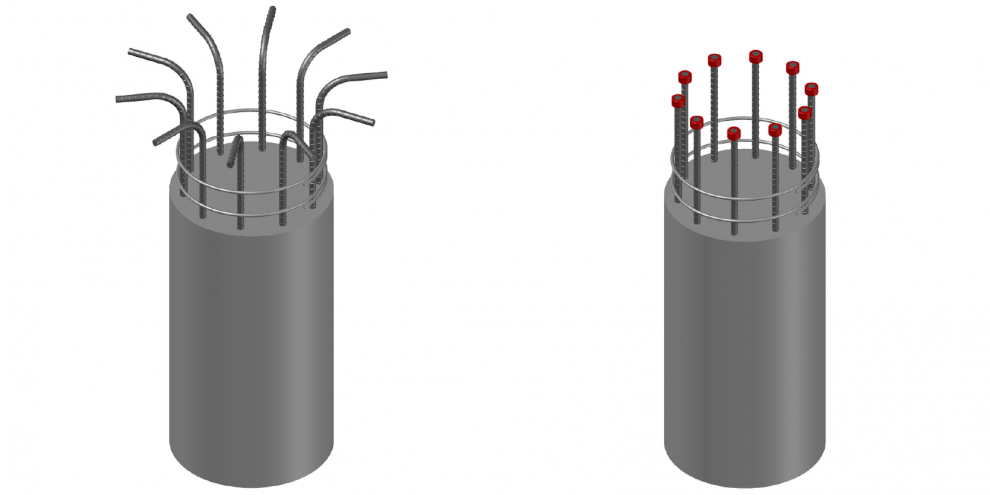

Cast-In Channel For The Malaysian Parliament House

Project: The Malaysian Houses of Parliament (Phase 3B)

Contractor: Public Works Department Malaysia

Product Supplied: HALFEN Cast-in Channel

Project Description

The construction of an annexe to the iconic Parliament Building of Malaysia has been recently completed where it includes office space, library, gymnasium, discussion rooms, meeting rooms and cafeteria.

The entire annexe is covered with the pineapple-skin-like facade, which is made of aluminium with 11 feet in height and 40 inches in width. The cohesive arrangement is repeated throughout the façade, giving flow and movement to it. Apart from that, the design of the facade helps to control the amount of sunlight in the building while the wall is made of glass panels.

The Solution

HALFEN medium duty anchor channel HTA-CE 40/22 has been chosen for the fixing of brackets of the curtain wall installation of this project. With the efficient and versatile support of high loads, the cast-in channel ensures a safe, reliable and efficient anchorage of the aluminium façade to the wall of the building, where it replaces traditional alternative methods such as drilling and welding. Using a cast-in channel also helps to avoid the risk of damaging the concrete and reinforcement which may be caused by drilling. Made of high-quality stainless steel A4 material (equivalent to AISI 316), the HALFEN cast-in channel is able to meet the demanding sustainability requirements of this project and guarantee the intended design life span since the cast-in channels will be exposed to the weather.

Cast-in channels are positioned securely to the formwork so that no movement occurs during the laying reinforcement and to ensure the compacting of concrete. With the plannable assembly times on-site, this helps our client to plan the construction timeline accurately.

The installation of the cast-in channel is completed with simple hand tools without any drilling of concrete or site welding. Quality control of the installation is verified easily by visual check; when compared with post-installed anchors, the checking of post-installed anchors is only possible via testing. Not to mention, the quality and performance of post-installed anchors rely heavily on the professional execution of site activities by skilled workers.

HALFEN cast-in channel provides flexible fixing of mountings along the channel slot to accommodate building tolerances during the installation or throughout its life cycle.

The Result

With the advantages that our clients are benefiting from, it is clear that why the HALFEN cast-in channel has been the preferred option for the construction of the unique façade design of this iconic building. Apart from excellent adjustability, HALFEN cast-in channels save considerable installation time. The result: Faster completion of the construction project with reduced cost.

Leviat offers full guidance on selecting and designing the right cast-in channel system according to the right connections under the right loading conditions. Hence, regardless of the location or the loading, our clients are all assured of the highest level of safety.

Related Articles You May Be Interested

The Difference Between Pre-Tensioning And Post-Tensioning

Pre-tensioning system vs Post-tensioning system

With Pre-Tensioning, the tendons are tensioned against the abutments before the concrete is place. Once the concrete is hardened, the tension force is released and cut off after getting the required strength of the concrete to transfer the pre-stress on the concrete member. The tendon tries to shrink back to the initial length but the concrete resists it through the bond between them, thus, compression force is induced in concrete. Pre-Tension is usually done with precast. Wedge and barrel are the two components required to hold the tendons or pre-tensioning wires tightly when it is pulled out for inducing tensile force. The barrel will have tampered finish into which the wedge will get locked as the force increased.

Post-tensioning is a technique for reinforcing concrete. With Post-Tensioning, the tendons are tensioned after the concrete has hardened. Commonly, corrugated ducts are placed inside the concrete along the centroidal axis before casting. After the concrete has hardened and had enough strength, the tendon was placed inside the duct, stressed, and anchored against concrete. Space remains in the duct is filled with mortar by grouting. Post-Tensioning can be done either as precast or cast-in-place.

Post-tensioning vs Conventional

Post-tensioned concrete is stronger and more flexible than conventional steel-reinforced concrete. Post-tensioning helps reduce cracking from shrinkage as the concrete dries, and holds together any cracks that do form.

Summary

| Pre-Tensioning | Post-Tensioning |

| Pre-tensioning is done in the factories thus suitable for precast construction works. | Post-tensioning can be done in factories as well as on the site. |

| In this type of concrete, the pre-stressing cables called the strands are tensioned before casting the concrete and then concrete is cast enclosing the tensioned cables. | In this type of concrete, the strands are enclosed within a duct in the form and then concrete is cast. The process of tensioning the strands is carried out after the concrete attains its sufficient strength. |

| Small sections are to be constructed. | The size of a member is not restricted, long-span bridges are constructed by post-tensioning. |

| Pre-tensioning members are produced in a mould. | Cables are used in place of wires and jacks are used for stretching. |

| The concrete is prestressed with tendons before it is placing in position. | Prestressing is done after the concrete attains sufficient strength. |

| Pre-tensioning is preferred when the structural element is small and easy to transport. | Post-tensioning is preferred when the structural element is heavy. |

First Large-Scale Underground Substation In Southeast Asia

Project: Labrador Substation, Singapore

Contractor: Hyundai Engineering & Construction Co. Ltd.

Product Supplied: MOMENT JoinTec Coupler

Project Description

MOMENT Rebar Coupler is being supplied to the first large-scale underground substation in Southeast Asia. Located at Pasir Panjang, Singapore, the 230-kV electrical substation underground is being built to optimize space in land-scarce Singapore for urban growth and development.

By going underground, the Labrador substation will free up 3 hectares of prime land space (equivalent to the size of 4 football fields) for a 34-storey of commercial development. When in service, the substation will serve the electricity needs of up to 8 nearby towns.

The Solution

In order to deliver a robust, safe and yet timely construction, a peanut-shaped double cell retaining wall system each with a diameter of 95m using diaphragm walls is being built. Combined with the raft foundation, it works as both a foundation and a base slab.

To enhance the integrity and strength of the diaphragm wall, the MOMENT JoinTec Coupler has been used to connect the rebar cages vertically, allowing to achieve longer cage length (instead of the conventional lapping method). This is because lapping rebar in a heavily reinforced rebar cage can cause significant congestion, resulting in problems fixing the steel and insufficient room for the proper placement and compaction of the concrete. Hence, the use of MOMENT JoinTec couplers significantly reduced the congestion, making the placement and compaction of the concrete easier, leading to less risk of concrete segregation due to over vibration and as a result an increase in the concrete quality.

Furthermore, with the large rebar diameters of 32mm to 40mm is used for the diaphragm wall, rebar couplers are strongly recommended by our experts, where splitting and dowel action forces can be significant. Eurocode 2 states: “Generally large diameter bars should not be lapped. Exceptions include sections with a minimum dimension 1.0m or where the stress is not greater than 80% of the design ultimate strength” and “Splitting forces are higher and dowel action is greater with the use of large diameter bars.”

In addition, the safety advantages of rebar couplers do not come at the expense of constructability. In fact, the use of MOMENT rebar couplers for this project is helping the on and off-site construction easier and faster as well as safer. The prefabricated rebar cages for the diaphragm wall can be easily connected on-site, making on-site welding of rebar unnecessary. Besides, the use of rebar couplers allows the face of concrete elements to remain smooth during construction (avoiding hazardous protruding rebars), making construction easier and faster.

The Result

In spite of confronting the challenges of the pandemic, the venture able to meet the planned timeline. Utilizing approximately 200,000 pieces of MOMENT JoinTec Coupler, a mechanical splice of predominant quality and reliability; Labrador Substation, the primary large-scale underground substation is able to preserve its auxiliary integrity and vigorousness.

Related Articles You May Be Interested

Our Measures in Response to the Movement Control Order (MCO)

Dear Client and Business Partners,

In recent days, COVID-19 has dominated our thoughts and conversations. We at Leviat will do our part to prevent the spread of transmission and take care of our customers, co-workers and communities. Following the recently declared Movement Control Order to be imposed in Malaysia, the management of Leviat has implemented work from home (WFH) arrangements for our colleagues from these entities during this period.

The arrangement is aimed at ensuring colleague safety while also retaining adequate capability to continue servicing client needs. Our colleagues working from home remain contactable via both email and mobile, and can also conduct meetings via video and teleconferencing facilities. This enables us to maintain the high level of quality and consistency that you have come to expect from Leviat. While all efforts are focused on maintaining business as usual, we seek your understanding and patience should there be unexpected delays arising from disruptions in the supply and service chain.

Leviat team in Malaysia has always been guided by our core values of:

Safety; Above everything else

Innovation; We find a better way

Customer Focus; We put our customer at the heart of it all

Collaboration; We are stronger together

Integrity; We do the right thing

Hence, we will continue to pursue these values as we continue to single-mindedly focus on serving you to the very best of our abilities, despite the challenging weeks and months ahead.

Please reach out to Leviat representatives if you have any questions or concerns, call/WhatsApp our Hotlines at +6012-524 9956 or +6012-553 9956, or email us at info.my@leviat.com, or even live chat with us on our website from 9 am – 6 pm MYT.

Lastly, on behalf of Leviat in Malaysia, please stay safe and stay healthy.

Rob Van Haaren

Country Director

Leviat | South East Asia

Questions You Must Ask Before Buying Any Rebar Couplers

Rebar couplers, also known as mechanical splices are mechanical connections between two pieces of rebar that enable the bars to behave in a manner similar to continuous lengths of rebar. There is a range of couplers available in the market with different features, hence, each engineer should ensure that the right rebar coupler selected is able to meet the specific requirements of the project.

Here are some of the important questions you will need to ask before buying any rebar couplers:

Are the rebar couplers compliant to ISO 15835?

Strength and slip tests should be carried out according to ISO 15835. One should always request strength, slip test reports and product certifications to ensure fitness for purpose. Approved by CARES and CREAM certifications, our MOMENT JoinTec Coupler is compliant with ISO 15835 as well as most of the international code of practice and exhibits superior cyclic performance. It is designed to withstand an ultimate tensile strength of up to 700 MPa, thus resulting in Bar Break performance on most of the rebar available on the market.

Can the rebar couplers be traced?

Each rebar coupler should be marked with symbols to trace it back to the raw material and production batch data. Good suppliers should have detailed process flow control with accurate manufacturing drawings, hold points and QAQC measures. Process flows ensure continuity of production and consistency in quality. MOMENT rebar couplers come with an embossed serial number, ensuring that full traceability exists throughout the manufacturing process from the mill, through machining, processing and packaging to supply.

Does the rebar coupler come with a chamfered edge?

Chamfered edge helps to cope with axial misalignment, providing a positive alignment locking connection thus providing load path continuity. It is also safer to install a chamfered coupler, especially when hand tightening a parallel threaded rebar coupler during installation.

Are the rebar couplers manufactured using Computer Numerical Control (CNC) machines?

The use of a fully automated CNC machine ensures a highly accurate rebar coupler. This not only ensures that the thread is located centrally in the coupler, therefore avoiding unwanted bending moments, but also that well-matched threads were produced consistently when compared to manual tapping, where the accuracy and quality are highly dependable on the operator.

Is cold forging part of the rebar threading process?

The end of a bar has to be strengthened (normally cold-worked) to ensure that any reduction in the tensile (root thread) area of the original bar does not compromise the overall performance of the coupling, therefore making this type of coupler ideal in geographical areas prone to earthquakes where the formation of plastic hinges is essential for structural robustness. MOMENT rebar coupler system is supported by 3 high-productivity machines which prepare each bar in sequence: clean square cut, cold working of the bar end and then threading.

Do you have a team of engineers ready to support?

It is important to purchase rebar couplers from providers who have a team of engineers ready to provide assistance from design through to the completion of your development, eliminating the typical problems, surprises and costly delays. At Leviat, our qualified engineers offer additional services to our customers from technical support, product adaptation to installation, allowing customers to reach higher productivity with less hassle at construction sites.

To which projects the rebar couplers have been supplied?

Always request for the project reference list along with the types of products and the quantity supplied, this will help you to make an informed decision and to mitigate risk before making the choice.

MOMENT rebar coupler has been the market leader of the mechanical splice systems in Asia since 1991. Our rebar couplers have been delivered to a diverse range of projects from national government projects, buildings, transportation infrastructures, utility infrastratures to oil and gas sectors. One may always refer to our project references and clients’ testimonials on our website.

In conclusion, never compromise on quality and safety, it is always advisable to select the rebar coupler with the highest standards of quality and conformance to ensure its suitability regardless of the service conditions.

Uncertain Of Which Coupler Is Suitable For Your Project?

Let Us Drop You A Call For Consultation. For Free.

Related Articles You May Be Interested

Hybrid Precast Connection For Singapore’s Largest Independent Data Centre

Contractor: Obayashi Singapore

Precaster: Eastern Pretech

Product Supplied: MOMENT Hybrid Precast Connection

Project Description

Located in Singapore, the 60+ megawatt data center is set on 1.5 hectares, close to the Changi North Cable Landing Station for strong international interconnection. With over 20,000 square meters of data hall area, the scalable campus is designed for hyper-scale customers, supporting their rapid growth in Singapore and throughout South East Asia.

Designed to meet the stringent security requirements of global technology customers, this project is Singapore’s largest and most efficient independent data center, another pioneering independent hyper-scale data center in the Asia Pacific. It is a connected, secure, and efficient home for the cloud in Asia. This facility ensures the highest operational standards to provide customers confidence in terms of reliability and security.

The Solution

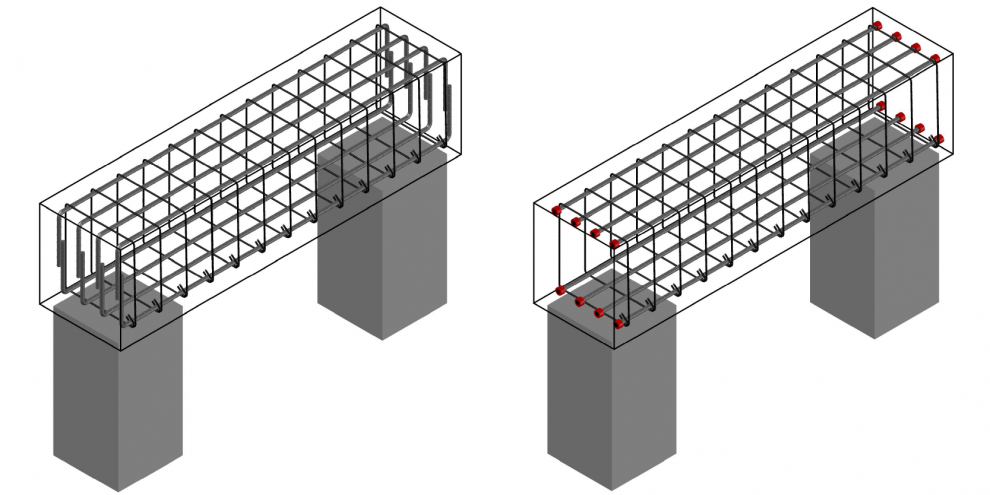

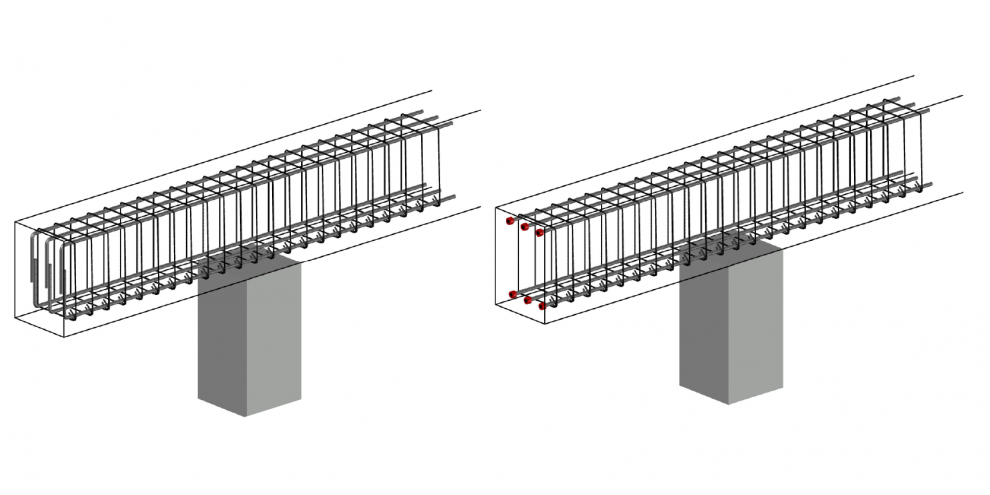

Challenge 1: Installation of the precast column using the full Precast Shoe solution for the initial phase was costly.

During the construction of the initial phase, the precast columns were installed using the full Precast Shoe solution which was costly to the client. Hence, the MOMENT Hybrid Precast Connection was introduced for the construction of Phase 2, where MOMENT Precast Shoes were used together with MOMENT Half Grout Couplers, offering substantial cost savings (up to 50%) when compared to a full Precast Shoe solution.

Challenge 2: The design of the precast column (a combination of precast column and crosshead) was too heavy to be lifted by a crane

The design of the precast columns consists of a combination of precast columns together with a crosshead. However, this design faced a challenge whereby the precast column was too heavy to be lifted by a crane. Hence, both precast elements were separated into two elements; the precast column and the precast crosshead. The MOMENT Hybrid Precast Connection was secured at the bottom of the precast crosshead and connected to the rebar protruding from the top of the precast column. With this, the load is divided but the connection remains strong to carry the load of the beam later.

Challenge 3: 1-year time frame to complete the project

The construction of this data center is aimed to be completed within a year, which is a stringent time frame for our client. However, with MOMENT Hybrid Precast Connection installed to the precast crosshead, the precast section can be lifted, placed, leveled and secured in less than 30 minutes. Once the Precast Shoes are installed, it is immediately loadbearing. Work can continue on the next precast element and later more than one assembly can be grouted, reducing both worker and crane time.

In addition, the MOMENT Grout Couplers cast in the precast column are grouted using the mass grouting method which is faster (compared to the individual grouting method) where the grout flows steadily from top to fill the Grout Coupler from bottom up to achieve robustness in a short period of time.

The Result

Approximate 500 precast columns have been installed using our MOMENT Hybrid Precast Connections. This shows that the combination of MOMENT Precast Shoe and MOMENT Grout Coupler offers many advantages over other building techniques, including substantial savings in cost and time, and improvements in site safety. Furthermore, we are able to provide a cost-saving solution that delivers the same robustness to the construction.

Constant Robustness Throughout Your Project.

Let Us Drop You A Call For Consultation. For Free.

Related Articles You May Be Interested

HALFEN Cast-In Channel – A Revolution For Tunnel Structure

HALFEN Cast-In Channel is the most forward-thinking and safe technique for fastening elements to concrete structures in tunnels.

Fully embedded in concrete, HALFEN Cast-In Channels provide permanently flexible anchoring lines in the concrete components. Adjustable and less dependent on the skill of the installer, they allow for simple compensation of construction tolerances and fast, predictable installation programs.

In particular in construction projects adopting precast technology like in tunnels with precast concrete lining (TBM), the application of Cast-In Channels offers great advantages. All the installation works are being done with high precision and under permanent control at the precast factory. This not only improves productivity and quality but also shortens construction time. There is no need for time-consuming & unhealthy dust-generating drilling on-site anymore. Safety issues related to the incorrect installation of post-installed anchors as well as health issues due to drilling operation can be eliminated and the risk of water leakage (water leakage is the main concern for most tunnels, particularly in Singapore) through possibly resulting cracks can be reduced!

The use of high-quality HALFEN Cast-In Channels has a thoroughly positive impact on the planning process, construction efficiency, and life-cycle cost. As fixtures can be enormously fast and adjustably mounted onto the Cast-In Channels during the initial tunnel fit-out phase and likewise throughout the entire operational phase, this forward-thinking fastening concept offers the highest degree of flexibility, allowing trouble-free modifications and refurbishments in the future.

Given the growing significance of safety, construction time, durability, and life-cycle cost, Cast-In Channels have become more and more preferred as alternatives to traditional methods.

The Right Channel For All Application.

Let Us Drop You A Call For Consultation. For Free.

Related Articles You May Be Interested