With the increase in reliance on precast concrete, Halfen Moment Group is ideally positioned to facilitate this transition due to its access to state-of-the-art connection technologies from its sister companies and partners in Asia, America and Europe.

One such technology is – Invisible Connections. It is a modern way of connecting precast concrete without use of corbels or angles.

TSS101

What is Traditional Technology?

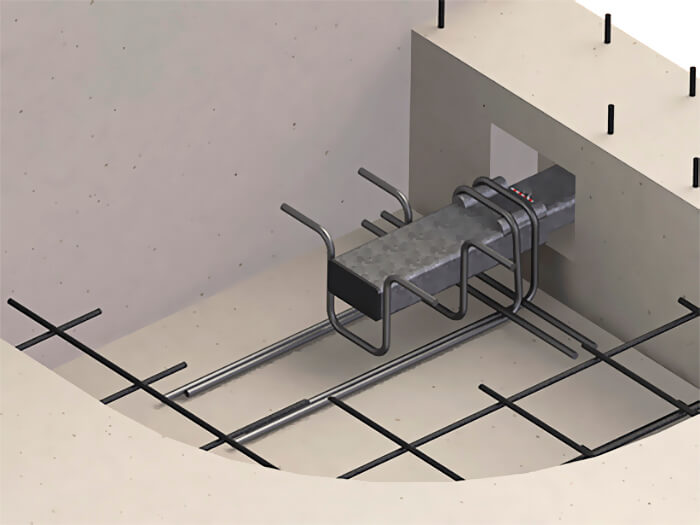

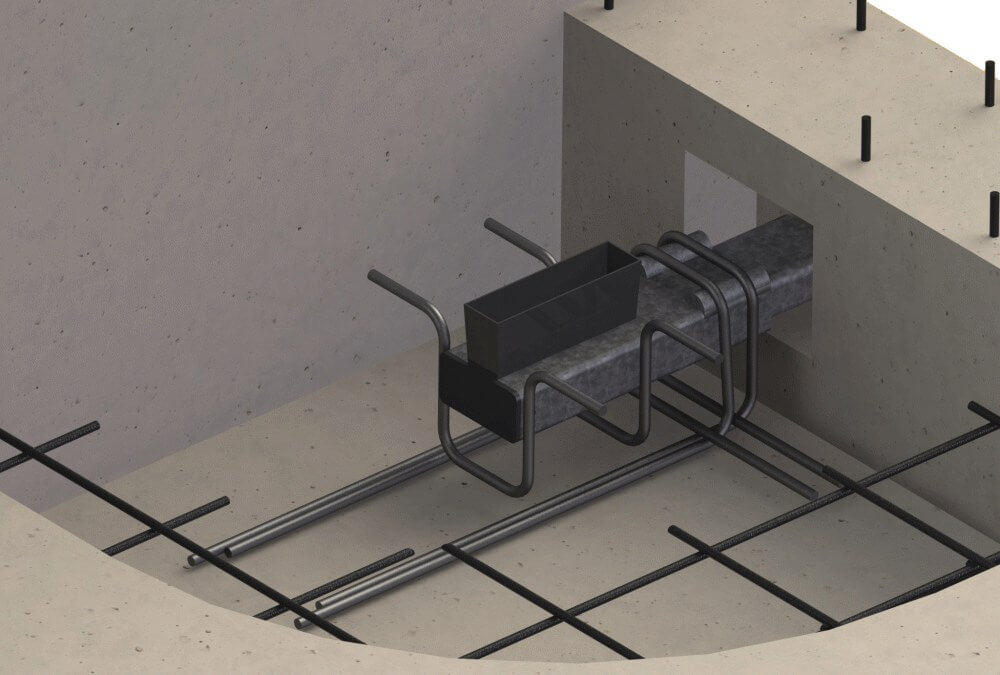

TSS telescopic connectors by Invisible Connections were developed specifically to address these problems. They are a proven technology developed in Norway and used extensively throughout Europe due to the independently tested and certified European Technical Approval (ETA) that provides engineers with peace of mind about their capacities.

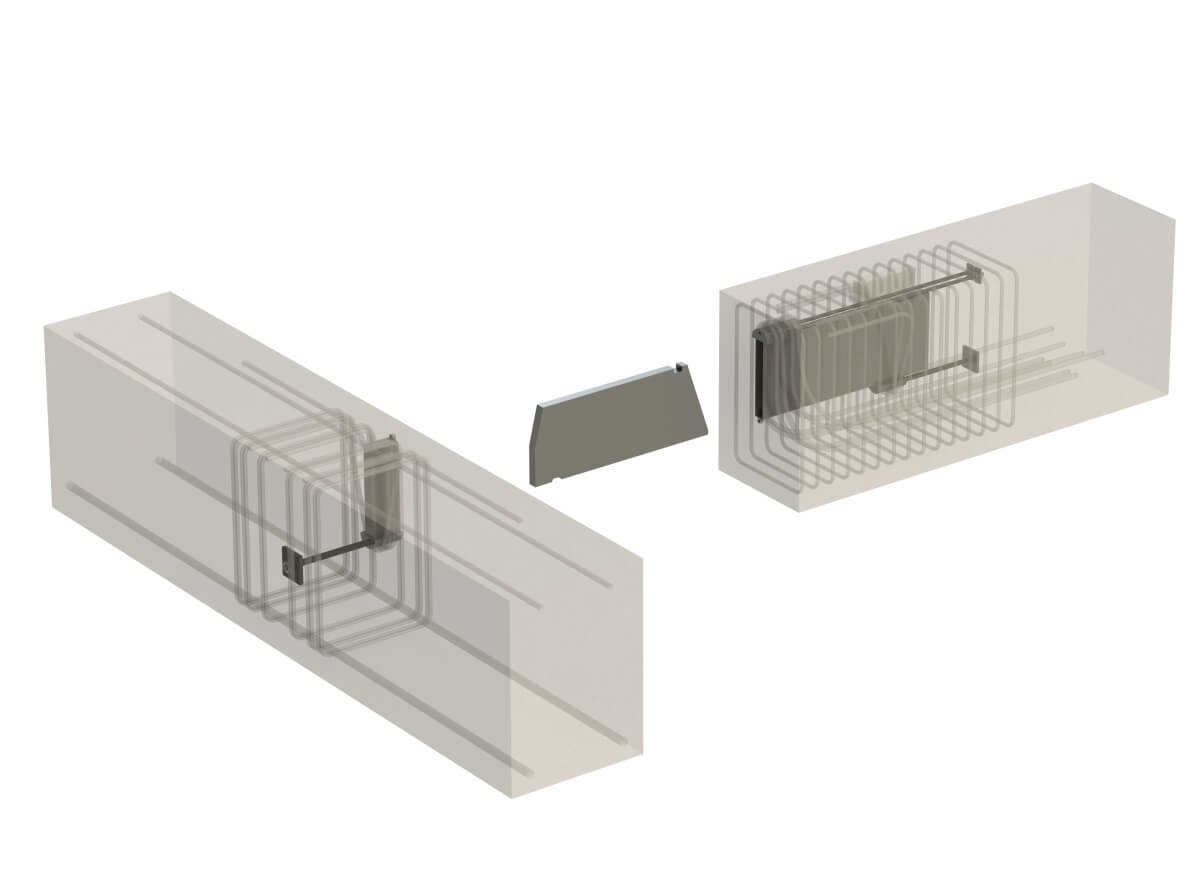

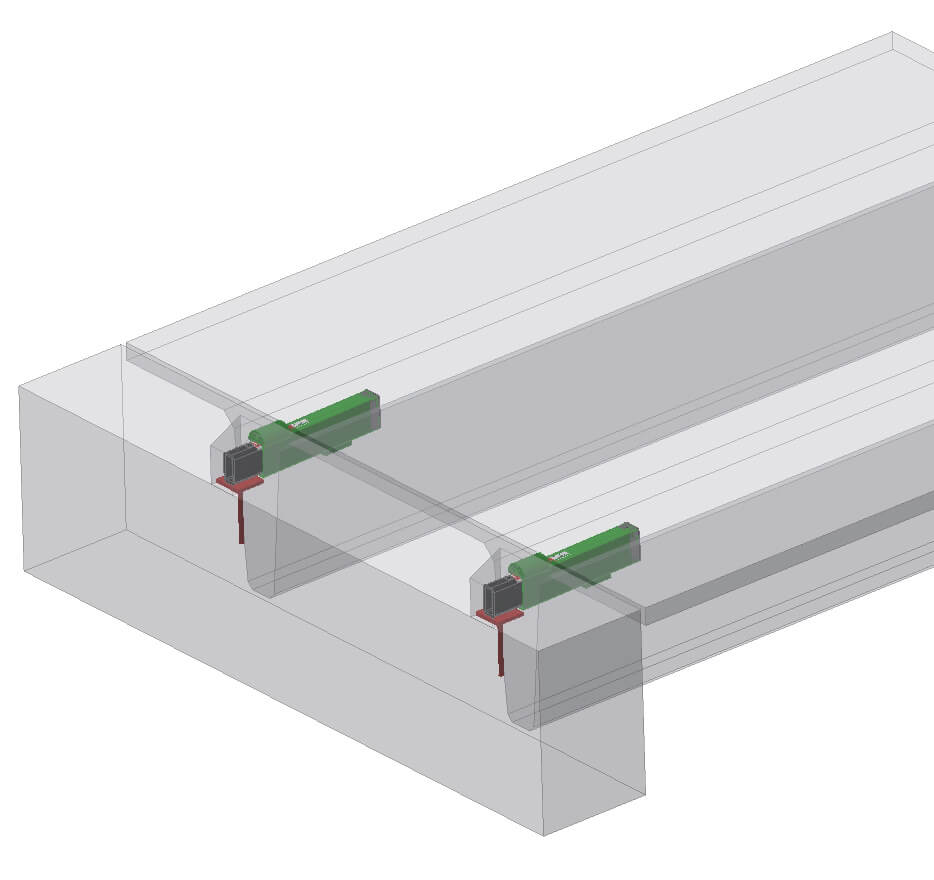

The TSS units are used for a concrete component with an exposed concrete finish such as a stair landing. When erecting the elements on site, the inner tube is pulled out with a wire to fit a recess in the wall with a safety device to ensure the inner tube is correctly located in the recess.

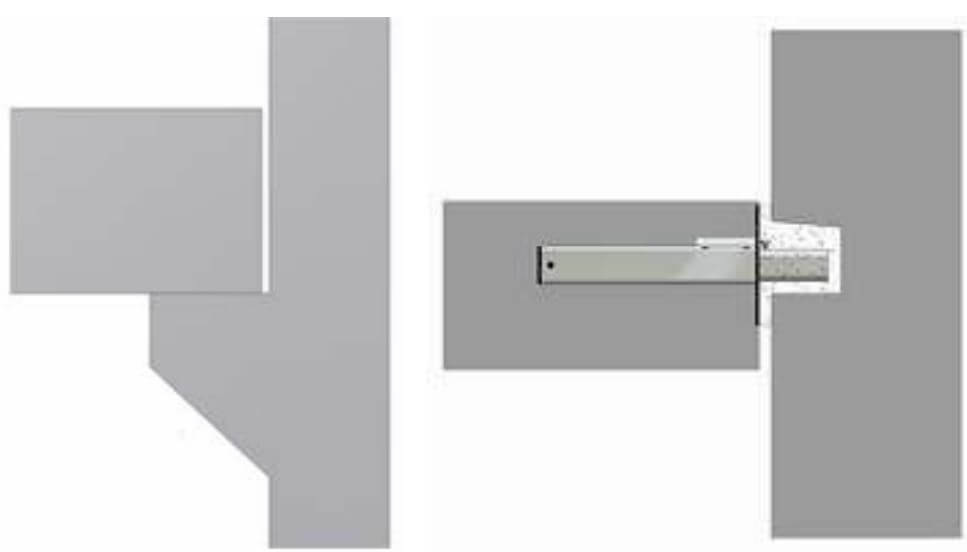

Conventional construction with corbel VS Corbel free construction using Invisible Connections

Why Invisible Connections?

Types of Invisible Connections

TSS & RVK

2) BSF For Precast Beam to Column Connections.

BSF

3) DTF/DTS For Precast Double T connections.

DTS

Advantages of Invisible Connections

After installation, there is an invisible connection, with no visible supports.

2) Reduce impact sound from the stairways

The Invisible Connection System has several ways for sound insulation. From the more ordinary to the remarkable sound reduction.

3) Safe and simple installation on site

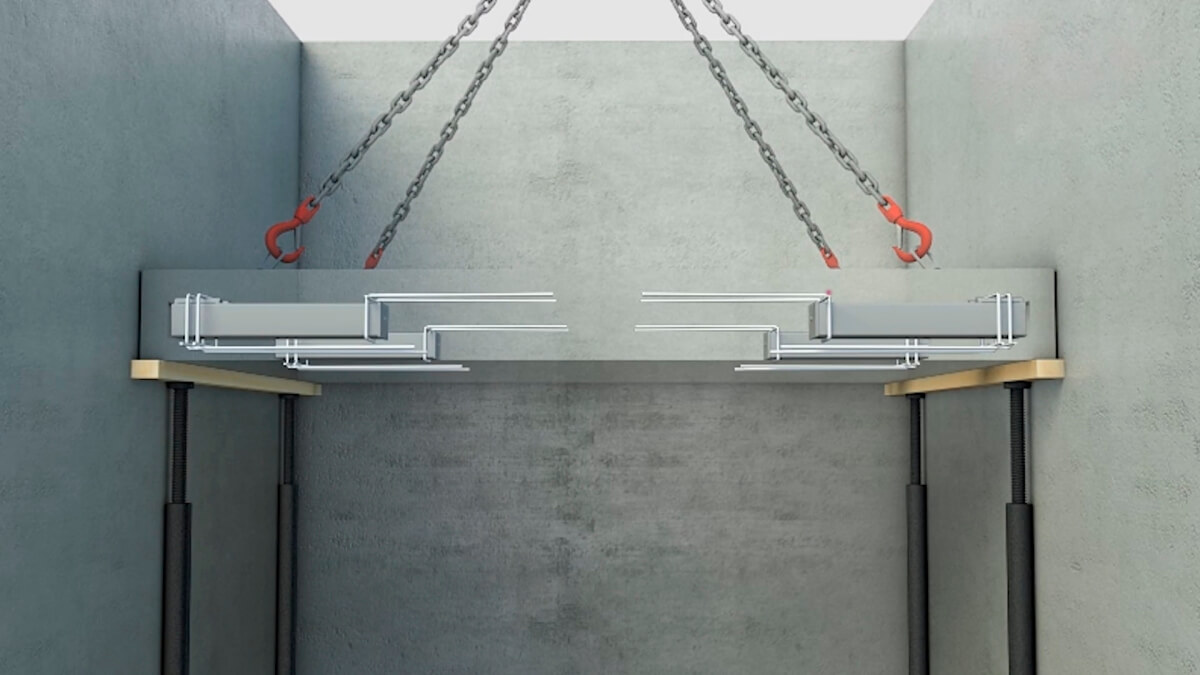

With a crane the elements are safe and quickly located in the shafts. The correct method is to support the elements from beneath, level the element and pull out the inner tubes into the recesses. For the permanent connection, the recesses are then filled with mortar.

4) No welding or bolting on site

By using our systems you avoid welding and bolting on site. Only filling up the recesses with mortar is needed. Uniform performance.

5) Simple design of walls

Easy to plan the recesses in both precast walls and in moulds on site, due to standard location and sizes. Less use of crane time on site. The installation time is shorter, compared to similar systems. Saving crane hours and money.

6) Standard box for wall recesses

The Invisible Connection System has also standard boxes for planning the recesses. These are corresponding to the size of the units. For steel moulds, they are magnetic.

7) Technical approved systems

The Invisible Connection System is ETA approved system.

No visible corbels and reducing the waiting time for the crane

For further details, please contact our Malaysia HQ office or visit our office where we can showcase you the actual Invisible Connections products!

Related Articles You May Be Interested