Revolutionizing High-Rise Construction with Rebar Couplers

In the ever-evolving world of construction, innovation and efficiency have become paramount. When it comes to erecting high-rise structures, one traditional practice that has seen a transformation in is the use of rebar couplers. For contractors still adhering to the conventional method of rebar lapping, it is time to consider the benefits that rebar couplers can bring to your high-rise projects.

Cost Savings That Soar High

Material Efficiency

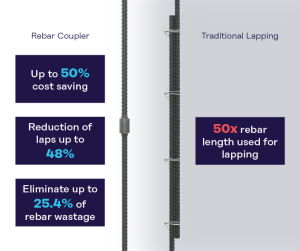

In the traditional method of rebar lapping, a significant amount of reinforcement steel is wasted in the overlapping sections. This not only translates into higher material costs but also increases the overall weight of the structure. Rebar couplers eliminate this waste by seamlessly connecting the bars, resulting in substantial material savings.

Faster Construction

Time is a critical factor in high-rise construction, and delays can be costly. Rebar couplers enable a faster construction pace as they eliminate the need for time-consuming manual labor, such as bending and securing overlapping bars.

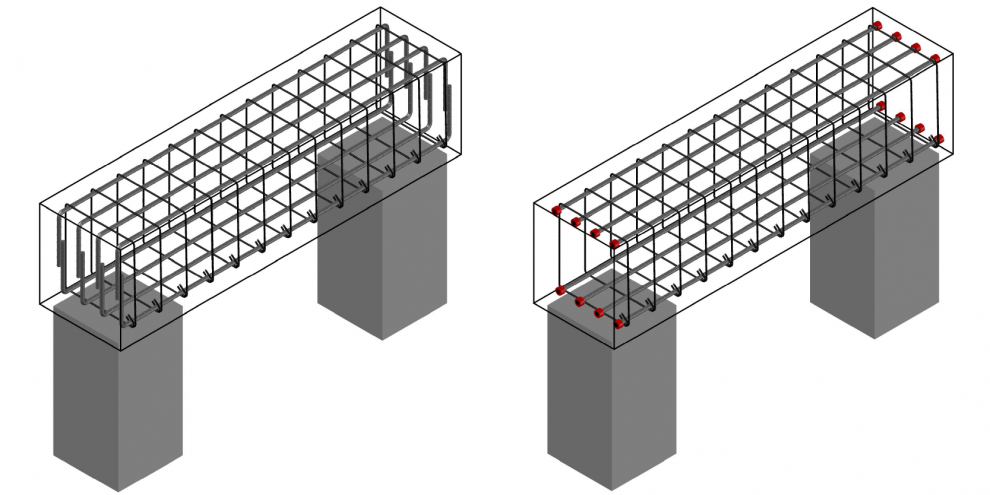

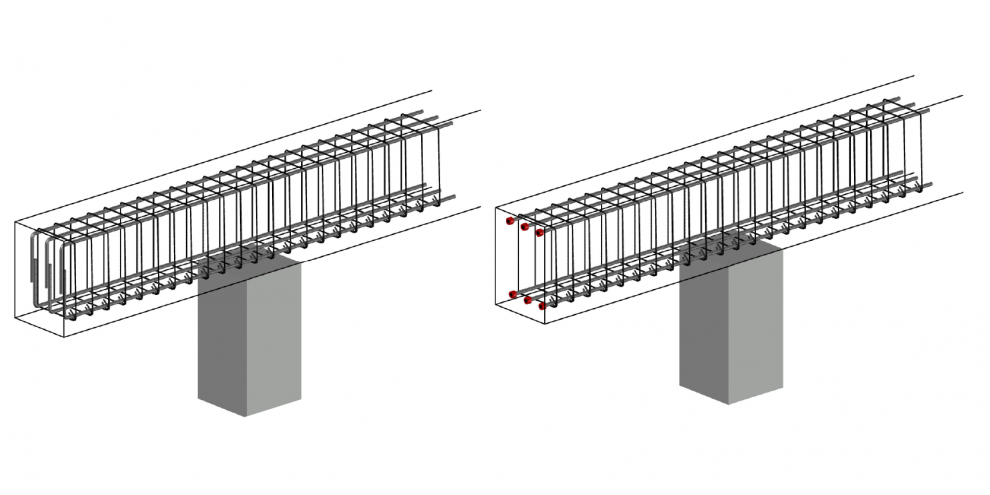

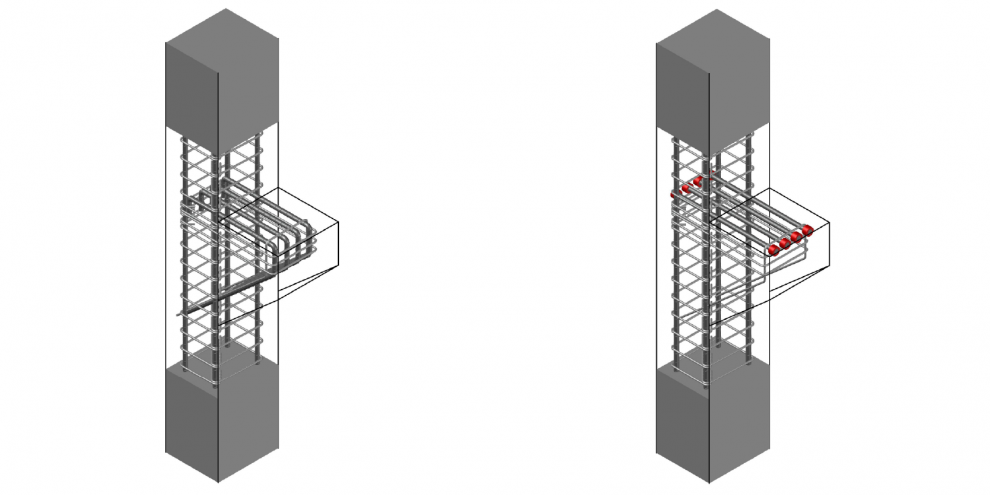

Addressing Space Constraints

Unlike traditional lap splicing, which exacerbates congestion issues in the rebar lap zone, mechanical splices alleviate these problems. This reduction in congestion not only prevents the formation of rock pockets and voids in the concrete but also results in improved concrete consolidation.

All the above challenges were addressed in one of our earlier article. You may read the article here: Mechanical Splices vs Lap Splicing.

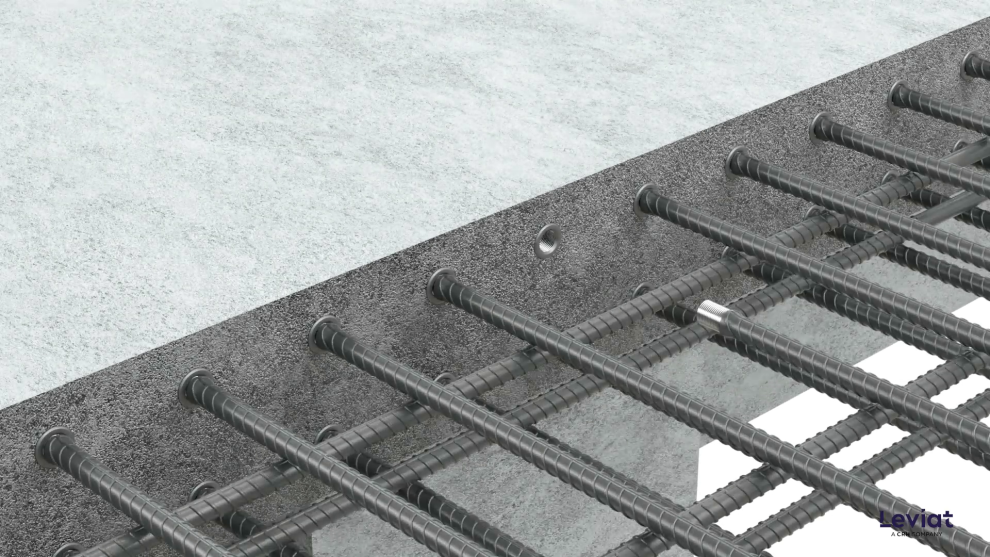

Application for Every Situation

Rebar couplers are indispensable for having secure connections between crucial structural elements in high-rise construction, including beams, columns, slabs, lift core walls, and pile caps. Their versatility and reliability make them essential components in ensuring the structural integrity of these towering buildings.

However, the reality of construction sites is that they often introduce unforeseen complexities. These challenges can stem from limited space, specific project requirements, or various other factors unique to each site. To effectively navigate this dynamic environment, three primary methods have emerged for the installation of rebar couplers.

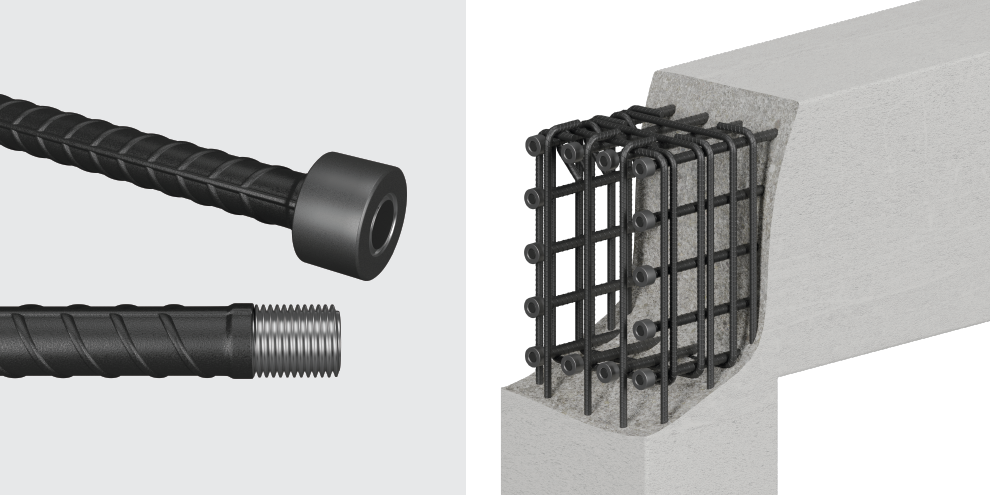

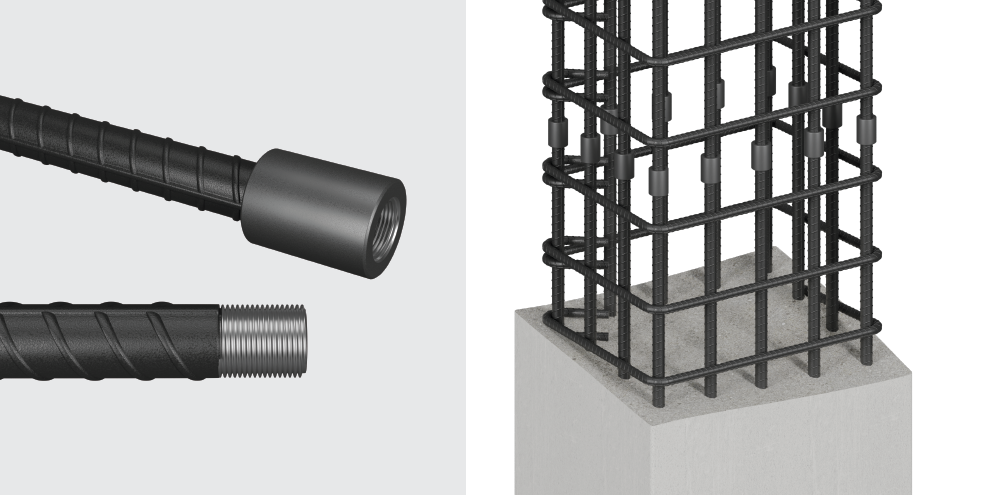

Situation 1: Rebar with Ample Space for Rotation (Type A)

In this scenario, there is sufficient space and flexibility to rotate the rebar. Type A installation involves seamlessly connecting two rebars by simply rotating them, ensuring a secure and efficient bond.

Situation 2: Rebar with Limited Rotation (Type B)

When the rebar can be rotated but with some difficulty, Type B installation comes into play. This method involves rotating the coupler from a full-thread rebar to a half-thread rebar, allowing for a secure connection despite the limited rotation.

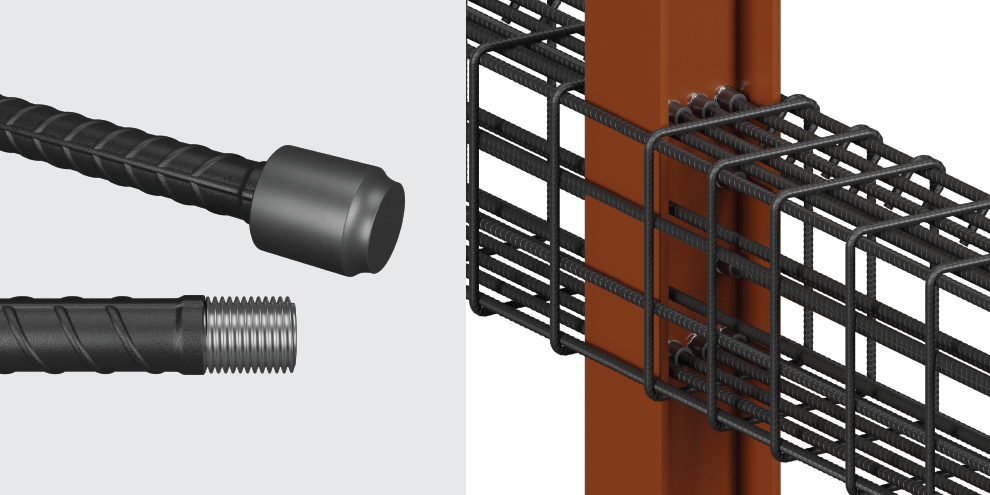

Situation 3: Non-Rotatable Rebar (Type C)

In situations where the rebar cannot be rotated at all, Type C installation is the solution. It involves rotating the coupler from an extended-thread rebar and further strengthening the connection using a lock nut. This method ensures a reliable and robust bond even when rebar rotation is impossible.

Moment JoinTec Coupler in High Rise Architecture

Let the results speak for themselves. High-rise contractors, just like you, have witnessed remarkable outcomes through the use of Leviat’s Moment rebar couplers. Here are a few examples:

KLCC Twin Towers

Tun Razak Exchange (TRX)

Merdeka 118

The construction industry is continually evolving, and high-rise contractors must adapt to remain competitive. Rebar couplers offer a compelling solution for those seeking cost savings and increased efficiency in their projects. By making the switch from the traditional method of rebar lapping to the modern approach of rebar couplers, contractors can not only reduce costs but also expedite construction timelines and enhance the overall integrity of their structures.

Contact our Leviat engineering experts for a personalized consultation today!

Rebar coupler to satisfy rapid constructions development

Accelerated construction growth demands quality connection, efficiency and operability.

In recent years, the demanding design in concrete, new materials and development of composite structures have prompted designers to consider alternatives to lap splicing or welding to connect reinforcing bars. The insufficiency of lap splicing and welding rebar is inadequate for modern construction needs. As such, gone are the days of lap joints or splices—where rebars are connected with time-consuming splicing or expensive welding. Enter the rebar coupler to provide better safety, sustainability, and, most importantly, cost reduction.

The advancement of steel thread coupler technology enables rebar couplers to bring quality connectivity, efficiency and operability to such construction needs. The rebar coupler is the perfect fit for today’s construction methods.

What are rebar couplers?

Joining rebars with couplers, which is mechanical splicing, is not foreign in the industry. However, the applications of rebar couplers are yet to become the norm.

Mechanical splicing is the connection between two reinforcing bars enabling the bars to behave like continuous lengths of rebar. Couplers, small steel connectors, are used for the connection with total tension capacity. Commonly, the threaded system is used. It’s simple, brilliant design reduces the amount of reinforcement required.

Why use rebar couplers & the benefits of a continuous rebar

Traditionally, lapping reinforcements are inevitable in concrete buildings to ease transportation and handling of rebars. The two lap-spliced reinforcing bars depend heavily on the concrete bond for load transfer. The reinforcements will be unstable under their lengthy vertical weights. Lapping is also naturally wasteful and possibly leads to heavy reinforcement congestion in the section of a concrete member. Conversely, welding bars are considerably more expensive depending on the chemical properties and weldability of the rebars. They also vary in performance as they rely on the welder’s skills and the metallurgy of the rebar.

Reduce congestion of rebars

Congestion happens in the lapping of reinforcement as the steel-to-concrete ratio doubles. It makes placing and compacting concrete challenging, which may significantly affect the structural integrity of the finished structure. Using rebar couplers eliminates this problem.

Independent of surrounding concrete

The transfer load of lap joints depends heavily on the bonding of the surrounding concrete. Hence, degradation or poor compaction could affect the performance of the splice. When the two reinforcing bars behave as a continuous unit using rebar couplers, concrete is not needed for load transfer, promoting full strength in tension.

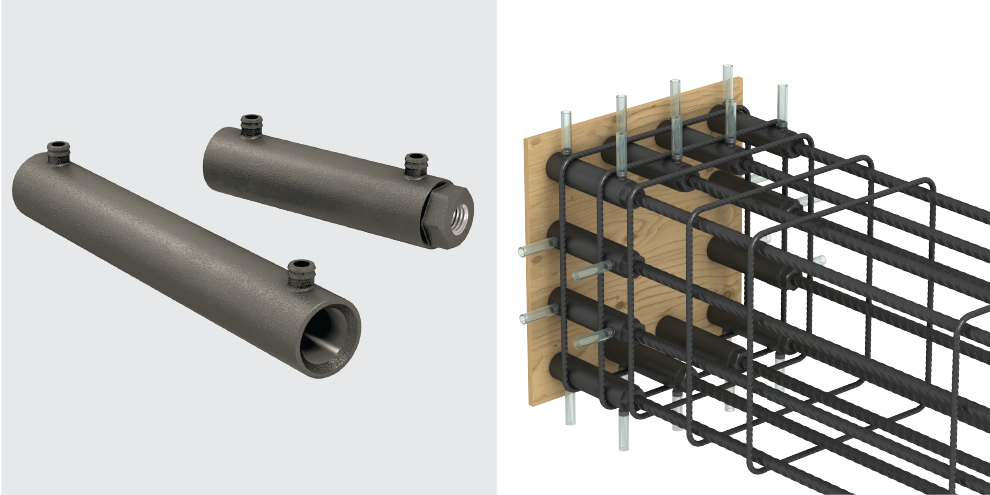

No damage to the formwork

Previously, preparing starter bars with them projecting through the formwork generated loads of challenges. Namely, safety hazards of protruding bars, the need for perfect predrilled holes accurately positioned in timber formwork, the time-consuming process of drilling holes in concrete and filling it with resins, and many others. Using rebar couplers to connect starter bars will eliminate all of these challenges.

Save costs

With rebar couplers, construction projects use less steel. Thus, eliminating wastage and unnecessary rebar costs by up to 40%. It is also proven that rebar couplers significantly reduce construction time and reinforcing steel. Other costs rebar couplers may save include

- Material wastes from overlap splices

- Cost-efficiency on overall project costs with larger rebar size

- Rebar and freight costs

- Job site problems due to rebar congestion

- Damages on costly forms rendering the form unreusable

- Labour, designer and detailer costs

- Delayed project schedule due to installation inefficiency.

Contribute to sustainability goal

Reinforced concrete structures use enormous amounts of concrete and rebar during the construction phase. Rebar contributes the most CO2 per unit weight compared to other resources. Did you know rebar contributes about 9.2 times embodied CO2 (ECO2) over concrete? Also, mechanical rebar couplers significantly reduce the amount of ECO2 by at least over 80% compared to splice lap. Using couplers to connect rebars can build a greener and lighter building, enabling the optimisation of rebar work and achieving project sustainability goals.

Rebar Couplers Types & Application

Generally, there are many coupler systems in the market for various applications. Leviat, a CRH company, features a suite of coupler systems of industry-trusted brands such as MOMENT and Ancon.

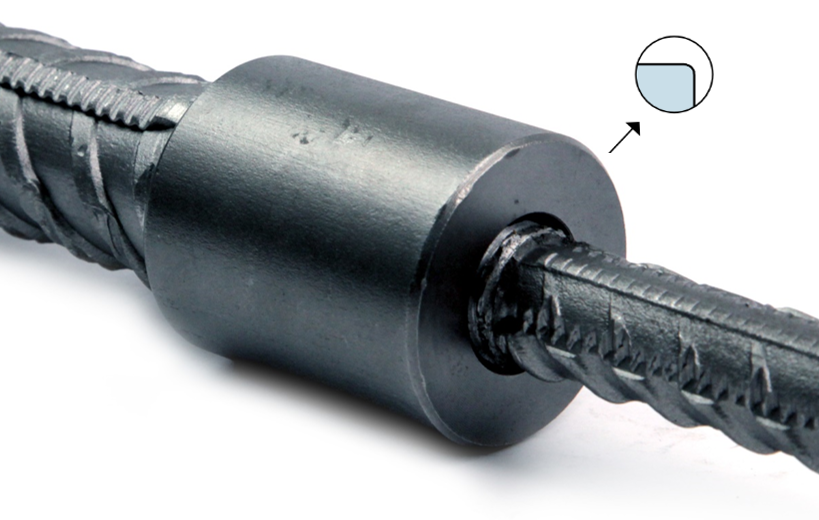

The renowned MOMENT JoinTec Coupler ensures a full performance splicing joint with its proof stressed bar ends. The extended long thread provides swift installation by simply turning the coupler instead of the bar. Its parallel thread assures a positive alignment, locking the connection and maintaining continuity and structural integrity.

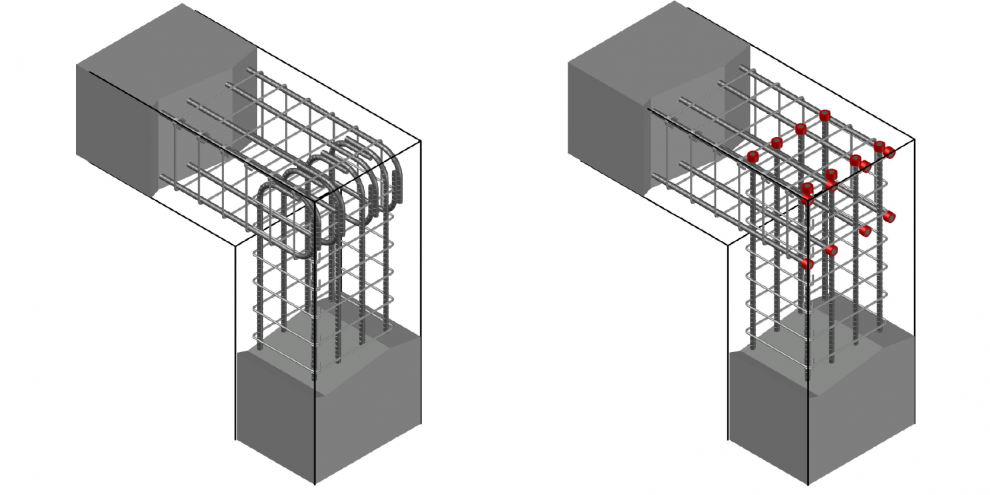

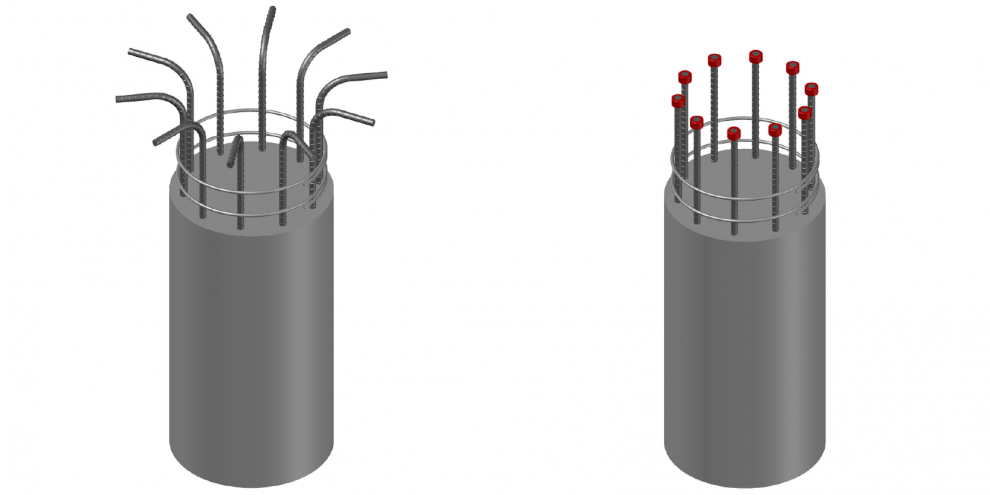

The MOMENT Terminator Coupler assembly, on the other hand, eliminates congestion and placement problems in heavily reinforced compact concrete structural members in the anchorage zones, typically posed by hooked rebar embedment lengths. It can be used to fully develop the bar instantly at the surface of the head for tying pile changes into capping beams or curtail reinforcing bars.

The MOMENT Weldable Coupler is designed for connecting reinforcing bars to structural steel members such as plates, piles, beams, columns, and more. It is effective and safe to connect steel and concrete when the structure is composite.

For high cycle elastic fatigue applications, maintaining values over the design strength of the bar is essential. For this, the MOMENT RT Coupler offers full strength with an alternative threading technology capable of exceeding the nominal ultimate characteristic strength of the bar.

The MOMENT Grout Coupler is uniquely designed for precast concrete connections with high flexibility and tolerance. When coupled with the MOMENT JT threaded system, and the MOMENT’s proprietary 100MPa grout can carry high loads exceeding the strength of the rebar.

The Ancon MBT Coupler is ideal for alteration or refurbishment projects. Particularly useful when the fixed bar is already in place with insufficient space for a hydraulic swaging press. This cost-effective coupler can achieve failure loads higher than 108% of the characteristic yield strength of grade 500 reinforcing bar.

The need for a more efficient splicing system is increasing due to increasingly complex constructions and design requirements. Leviat’s reinforcement rebar couplers can simplify the design and construction of reinforced concrete and reduce the amount of reinforcement required.

How to make smart rebar coupler purchases

Here are tips on essential questions to ask before buying any rebar couplers.

1. Are the rebar couplers compliant with ISO 15835?

Suitable rebar couplers have gone through strength and slip tests according to ISO 15835. So always ask for strength, slip test reports and CARES and CREAM certifications to ensure fitness. The MOMENT JoinTec Coupler is compliant with ISO 15835 and most of the international code of practices and exhibits superior cyclic performance. It is designed to withstand an ultimate tensile strength of up to 700 MPa, resulting in Bar Break performance on most of the rebar available on the market.

2. Can the rebar couplers be traced?

All rebar couplers should carry symbols traceable to the raw materials and production batch data. Good suppliers have detailed process flow control with accurate manufacturing drawings, hold points and QA/QC measures. It ensures continuity of production and quality consistency. Leviat’s rebar couplers come with embossed serial numbers, ensuring full traceability throughout the manufacturing process from the mill through machining, processing, packaging and supply.

3. Does the rebar coupler come with a chamfered edge?

Chamfered edge helps cope with axial misalignment, providing a positive alignment locking connection and thus providing continuity of the load path. It is also safer to install a chamfered coupler, particularly when hand tightening a parallel threaded rebar coupler. All Leviat’s couplers are made with chamfered edges.

4. Are the rebar couplers manufactured using Computer Numerical Control (CNC) machines?

A fully automated CNC machine produces a highly accurate rebar coupler. It ensures the thread is centrally located in the coupler, avoiding unwanted bending MOMENTs. Also, well-matched threads are consistent compared to manual tapping, where the accuracy and quality are highly dependable on the operator. Leviat’s couplers are made on fully automated CNC machines.

5. Is cold forging part of the rebar threading process?

Cold-worked strengthening of the end of the bar ensures the tensile (root thread) reduction does not compromise the overall coupling performance. This type of coupler is ideal for geographical areas prone to earthquakes where the formation of plastic hinges is essential for structural robustness. MOMENT JoinTec Coupler systems are supported by three high-productivity machines where each bar is prepared in the sequence of clean square cut, cold working of the bar end and then threading.

6. Does the provider have a team of engineers ready to support?

From design through to the completion of your development, you will need support in eliminating problems to avoid costly delays. Ensure the provider has a team of engineers ready to assist during your project duration. At Leviat, the qualified engineers offer additional services to customers, including technical support, product adaptation and installation advice, allowing customers to reach higher productivity with less hassle at construction sites.

7. What projects have used their rebar couplers?

Ask for a project reference list with supplied products and quantities to help you make an informed decision and prepare for risk mitigation. Leviat’s rebar couplers have an established application history in Asia since 1991. Their mechanical splice systems are delivered to a diverse range of projects from national government projects, buildings, transportation infrastructures, utility infrastructures to oil and gas sectors.

Conclusion

Rebar couplers bring quality connection, efficiency and operability to construction projects while saving costs with eco-benefits.

Related Articles You May Be Interested

The Alternative To Hooked Rebars

Whether you are trying to tie pile cages into capping beams or curtail reinforcing bars at the end of beams, heavy congestion or other constraints can often mean that bending or placement of bars is impossible, or at the very least, incredibly time-consuming.

Terminator Coupler is a simple and effective alternative to hooked rebars. It is secured to the end of the rebar, creating an anchorage within the concrete. The assembly of the rebar and the anchor provides an anchorage that is superior to long or bent rebars.

Being the replacement method of the conventional hooked rebar, the Terminator Coupler reduces the problems of rebar congestion in heavily reinforced compact concrete in the anchorage zones, which ultimately eases the compaction process, leading to a better concrete quality in key areas of the structure.

The front face of the coupler is generously designed to carry the full tension load of the rebar when the anchor is bearing against the concrete or structural steel.

For Designers

Terminator Couplers allow reducing steel congestion and steel to concrete ratios. They offer overall better buildability by making possible installation of anchors after the positioning of the rebar.

For Contractors

Terminator Couplers offer a fast, compact and easy-to-install alternative to hook bar, especially on large diameter reinforcement. Concrete flow is also favourably impacted. Rebar preparation can be outsourced or performed ahead of the installation without slowing down the operation.

For Cut & Bend Fabricators

Terminator Couplers are fully compatible with our JoinTec threading system.

Applications

Related Articles You May Be Interested

The Difference Between Pre-Tensioning And Post-Tensioning

Pre-tensioning system vs Post-tensioning system

With Pre-Tensioning, the tendons are tensioned against the abutments before the concrete is place. Once the concrete is hardened, the tension force is released and cut off after getting the required strength of the concrete to transfer the pre-stress on the concrete member. The tendon tries to shrink back to the initial length but the concrete resists it through the bond between them, thus, compression force is induced in concrete. Pre-Tension is usually done with precast. Wedge and barrel are the two components required to hold the tendons or pre-tensioning wires tightly when it is pulled out for inducing tensile force. The barrel will have tampered finish into which the wedge will get locked as the force increased.

Post-tensioning is a technique for reinforcing concrete. With Post-Tensioning, the tendons are tensioned after the concrete has hardened. Commonly, corrugated ducts are placed inside the concrete along the centroidal axis before casting. After the concrete has hardened and had enough strength, the tendon was placed inside the duct, stressed, and anchored against concrete. Space remains in the duct is filled with mortar by grouting. Post-Tensioning can be done either as precast or cast-in-place.

Post-tensioning vs Conventional

Post-tensioned concrete is stronger and more flexible than conventional steel-reinforced concrete. Post-tensioning helps reduce cracking from shrinkage as the concrete dries, and holds together any cracks that do form.

Summary

| Pre-Tensioning | Post-Tensioning |

| Pre-tensioning is done in the factories thus suitable for precast construction works. | Post-tensioning can be done in factories as well as on the site. |

| In this type of concrete, the pre-stressing cables called the strands are tensioned before casting the concrete and then concrete is cast enclosing the tensioned cables. | In this type of concrete, the strands are enclosed within a duct in the form and then concrete is cast. The process of tensioning the strands is carried out after the concrete attains its sufficient strength. |

| Small sections are to be constructed. | The size of a member is not restricted, long-span bridges are constructed by post-tensioning. |

| Pre-tensioning members are produced in a mould. | Cables are used in place of wires and jacks are used for stretching. |

| The concrete is prestressed with tendons before it is placing in position. | Prestressing is done after the concrete attains sufficient strength. |

| Pre-tensioning is preferred when the structural element is small and easy to transport. | Post-tensioning is preferred when the structural element is heavy. |

Questions You Must Ask Before Buying Any Rebar Couplers

Rebar couplers, also known as mechanical splices are mechanical connections between two pieces of rebar that enable the bars to behave in a manner similar to continuous lengths of rebar. There is a range of couplers available in the market with different features, hence, each engineer should ensure that the right rebar coupler selected is able to meet the specific requirements of the project.

Here are some of the important questions you will need to ask before buying any rebar couplers:

Are the rebar couplers compliant to ISO 15835?

Strength and slip tests should be carried out according to ISO 15835. One should always request strength, slip test reports and product certifications to ensure fitness for purpose. Approved by CARES and CREAM certifications, our MOMENT JoinTec Coupler is compliant with ISO 15835 as well as most of the international code of practice and exhibits superior cyclic performance. It is designed to withstand an ultimate tensile strength of up to 700 MPa, thus resulting in Bar Break performance on most of the rebar available on the market.

Can the rebar couplers be traced?

Each rebar coupler should be marked with symbols to trace it back to the raw material and production batch data. Good suppliers should have detailed process flow control with accurate manufacturing drawings, hold points and QAQC measures. Process flows ensure continuity of production and consistency in quality. MOMENT rebar couplers come with an embossed serial number, ensuring that full traceability exists throughout the manufacturing process from the mill, through machining, processing and packaging to supply.

Does the rebar coupler come with a chamfered edge?

Chamfered edge helps to cope with axial misalignment, providing a positive alignment locking connection thus providing load path continuity. It is also safer to install a chamfered coupler, especially when hand tightening a parallel threaded rebar coupler during installation.

Are the rebar couplers manufactured using Computer Numerical Control (CNC) machines?

The use of a fully automated CNC machine ensures a highly accurate rebar coupler. This not only ensures that the thread is located centrally in the coupler, therefore avoiding unwanted bending moments, but also that well-matched threads were produced consistently when compared to manual tapping, where the accuracy and quality are highly dependable on the operator.

Is cold forging part of the rebar threading process?

The end of a bar has to be strengthened (normally cold-worked) to ensure that any reduction in the tensile (root thread) area of the original bar does not compromise the overall performance of the coupling, therefore making this type of coupler ideal in geographical areas prone to earthquakes where the formation of plastic hinges is essential for structural robustness. MOMENT rebar coupler system is supported by 3 high-productivity machines which prepare each bar in sequence: clean square cut, cold working of the bar end and then threading.

Do you have a team of engineers ready to support?

It is important to purchase rebar couplers from providers who have a team of engineers ready to provide assistance from design through to the completion of your development, eliminating the typical problems, surprises and costly delays. At Leviat, our qualified engineers offer additional services to our customers from technical support, product adaptation to installation, allowing customers to reach higher productivity with less hassle at construction sites.

To which projects the rebar couplers have been supplied?

Always request for the project reference list along with the types of products and the quantity supplied, this will help you to make an informed decision and to mitigate risk before making the choice.

MOMENT rebar coupler has been the market leader of the mechanical splice systems in Asia since 1991. Our rebar couplers have been delivered to a diverse range of projects from national government projects, buildings, transportation infrastructures, utility infrastratures to oil and gas sectors. One may always refer to our project references and clients’ testimonials on our website.

In conclusion, never compromise on quality and safety, it is always advisable to select the rebar coupler with the highest standards of quality and conformance to ensure its suitability regardless of the service conditions.

Uncertain Of Which Coupler Is Suitable For Your Project?

Let Us Drop You A Call For Consultation. For Free.

Related Articles You May Be Interested

HALFEN Cast-In Channel – A Revolution For Tunnel Structure

HALFEN Cast-In Channel is the most forward-thinking and safe technique for fastening elements to concrete structures in tunnels.

Fully embedded in concrete, HALFEN Cast-In Channels provide permanently flexible anchoring lines in the concrete components. Adjustable and less dependent on the skill of the installer, they allow for simple compensation of construction tolerances and fast, predictable installation programs.

In particular in construction projects adopting precast technology like in tunnels with precast concrete lining (TBM), the application of Cast-In Channels offers great advantages. All the installation works are being done with high precision and under permanent control at the precast factory. This not only improves productivity and quality but also shortens construction time. There is no need for time-consuming & unhealthy dust-generating drilling on-site anymore. Safety issues related to the incorrect installation of post-installed anchors as well as health issues due to drilling operation can be eliminated and the risk of water leakage (water leakage is the main concern for most tunnels, particularly in Singapore) through possibly resulting cracks can be reduced!

The use of high-quality HALFEN Cast-In Channels has a thoroughly positive impact on the planning process, construction efficiency, and life-cycle cost. As fixtures can be enormously fast and adjustably mounted onto the Cast-In Channels during the initial tunnel fit-out phase and likewise throughout the entire operational phase, this forward-thinking fastening concept offers the highest degree of flexibility, allowing trouble-free modifications and refurbishments in the future.

Given the growing significance of safety, construction time, durability, and life-cycle cost, Cast-In Channels have become more and more preferred as alternatives to traditional methods.

The Right Channel For All Application.

Let Us Drop You A Call For Consultation. For Free.

Related Articles You May Be Interested

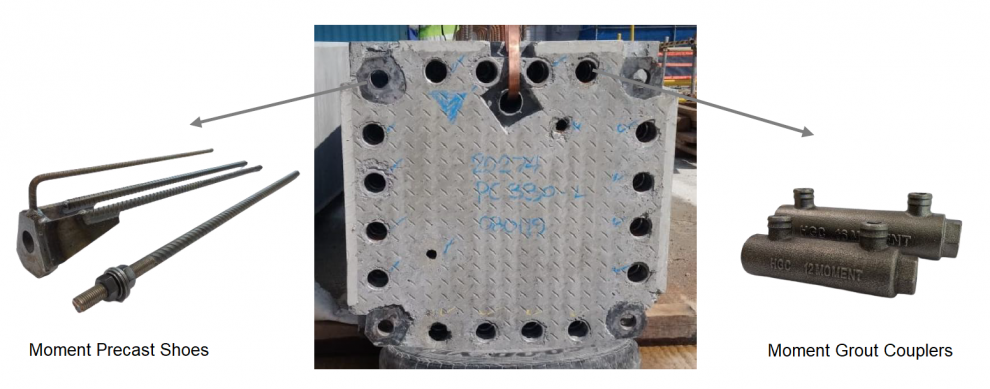

Hybrid Precast Column Connection

The MOMENT Hybrid Precast Connection is a construction method that combines the use of MOMENT Precast Shoes with MOMENT Grout Couplers to connect precast elements, such as precast column connection and elevator shaft connection. Using these two products in combination offers many advantages over other build techniques, including substantial savings in cost and time, and improvements in site safety. The bolted Precast Shoe connection with its unique ‘dry joint’ feature, makes the connection easier to be adjusted and immediately load bearing so that bracing is not required which results in less labor at site. Grout Couplers offer shorter development lengths (compared to traditional grout tubes), reducing the installation time in the precast factory by reducing the amount of confinement steel and enabling connections in much thinner elements. • Cost savings over other similar jointing methods To improve our clients’ productivity on site, MOMENT Hybrid Precast Connections have been applied in a few prominent projects in Singapore. Woodlands Health Campus, Singapore National Skin Centre, Singapore Air Trunk, Singapore Download Our Brochure For More Information Related Articles You May Be Interested Related Products You May Be Interested

MOMENT Precast Shoes

MOMENT Half and Full Grout Couplers

Benefits of MOMENT Hybrid Precast Connection

• Quick installation in the precast yard and on site

• Immediate load bearing before grouting

• No propping required on site

• Improved site safety and access

• Resists seismic loadsOur Project Reference

Connect Precast Elements The Efficient Way.

Let Us Drop You A Call For Consultation. For Free.

CARES Certified MOMENT Mechanical Splicing System

Leviat is proud to receive quality recognition of the MOMENT JoinTec Coupler system by the grant of approval in accordance with CARES Appendix TA1-F.

CARES is an independent, not-for-profit certification body that operates for the benefit of the construction industry, offering certification schemes for companies that produce materials or components for the reinforced concrete industry.

Download our CARES certification here.

MOMENT JoinTec Connection

MOMENT JoinTec mechanical connections conform fully with applicable codes, including BS 8110 Pt 1:1997 Clause 3.12.8.16.2 Bar in Tension and ISO 15835-1:2009. The MOMENT Jointec coupler system provides a ‘Bar Break’ solution with defined ductile behaviour, allowing the connection to perform like a continuous reinforcing bar.

Fig 1 – MOMENT JoinTec Mechanical Connection provides a ‘Bar Break’ solution as it performs in excess of the ultimate strength of the rebar.

Fig 2 – MOMENT JoinTec mechanical connections perform beyond the yield point of the bar whereas Lap Splices are only defined in the elastic area. This indicates that the MOMENT JoinTec connection, which work as continuous bars, provides additional strength and safety all-round, independent of the quality of the surrounding concrete.

Design Codes & Specifications

In reinforced concrete design, the Structural Engineer is faced with the task of determining where and how reinforcing bars must be spliced in a structure. This must be done to ensure that the national regulations are adhered to and also to make sure that the structure will not suffer a progressive collapse if overloaded.

Design requirements of the applicable codes, BS 8110 and EN 1992-1 generally assume a minimum connection strength but are silent on the details about test methods and conformity assessment. ISO 15835, which is used as the basis for the CARES approval scheme covers all aspects of coupler production and assessment including:

- To assess the serviceability, a test is made on a representative gauge length assembly comprising reinforcement of the size, grade and profile to be used and a coupler of the precise type to be used, the permanent elongation after loading to 0.6 fy should not exceed 0.10mm.

- It also covers tests for couplers to be used for mechanical splices in reinforced concrete structures under predominantly static loads and additional requirements for couplers to be used in structures subjected to high cycle elastic fatigue loading and/or too low cycle elastic-plastic reverse loading to represent seismic activities.

As most of the Southeast Asian countries progress in nation-building, federal governance, regulations and codes are becoming more stringent, MOMENT JoinTec connections, the proven mechanical splice method, provides you with the ability to design and build concrete structures to withstand the test of time.

MOMENT JoinTec Couplers were used extensively for reinforcement bars within the railway in MRT projects.

Recognized by:

Related Articles You May Be Interested

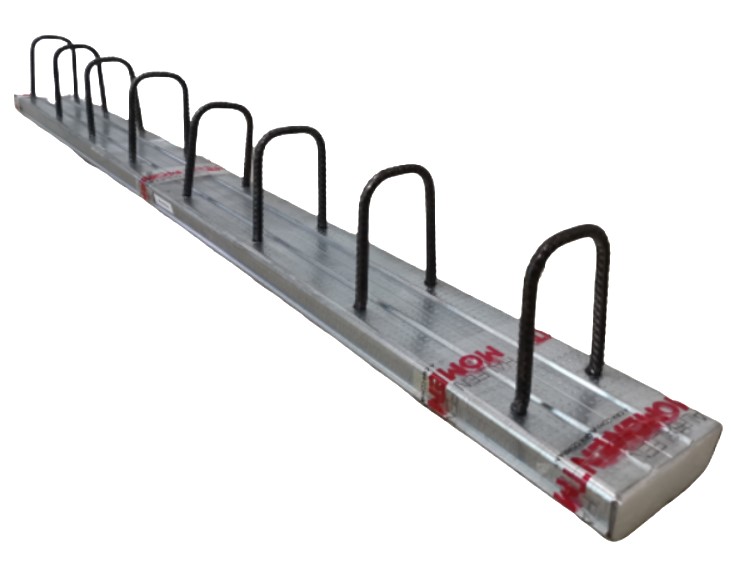

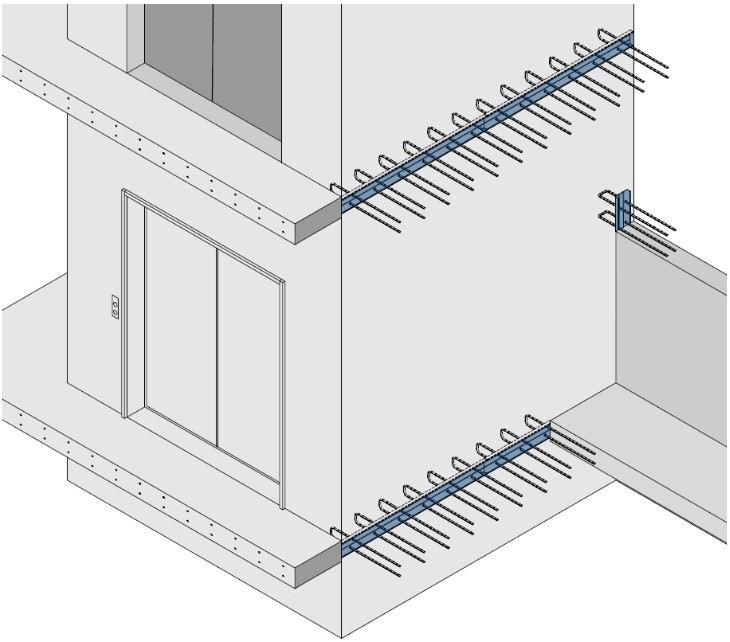

How To Maintain Reinforcement Continuity At Concrete Joints?

The concept and use of reinforcement continuity strip systems or ‘pull-out bar’ systems have been widespread in Asia & Europe over the last 30 years and is widely accepted means of providing reinforcement continuity across construction joints in concrete. The system utilizes the concept of overlapping reinforcement to provide a connection.

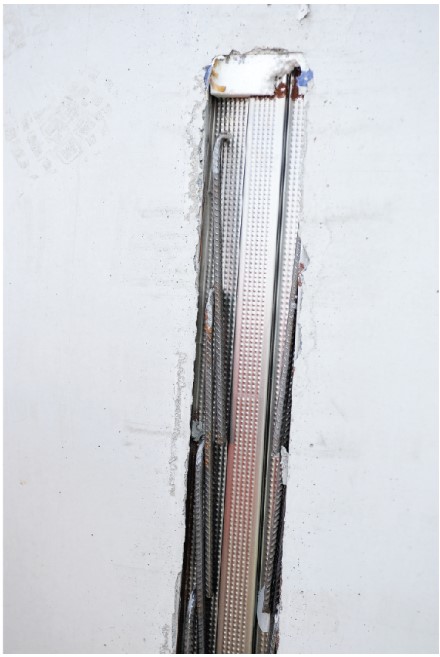

The MOMENT Bar Box system consists of specially selected, high yield reinforcing steel, housed in a galvanized steel casing with ribbed surface to provide an effective concrete bond. The end of the unit is sealed with a polystyrene block in order to prevent the ingress of concrete.

The Bar Box reinforcement continuity is manufactured using a reinforcing bar that meets the requirements of the local reinforcing bar standard.

Why Use MOMENT Bar Box?

The product design ensures fast and easy fixing by nailing to the formwork. Alternatively, it can be wired back to the main reinforcement cage. The concrete is then cast. After removing the formwork. The cover is removed and the bars are quickly straightened using the specifically designed rebend tool. The steel casing remains embedded in the wall and is filled with concrete when the next section is poured, the dimpled surface providing an efficient key.

When compared to traditional joint construction methods, the product offers a cost-saving by means of a less labour intensive installation process and simplification of formwork with the removal of the need to drill shuttering. This contributes to the acceleration of the construction process. As the bars remain enclosed within the casing until required, they are protected and the risk of injury from projecting bars is minimized. Easy to use, the system requires little onsite training in order to carry out the installation.

Most joints in concrete, on many different types of construction sites, have the potential to be formed using MOMENT Bar Box. It has been supplied to high rise commercial buildings, water treatment plants, hospitals, prisons, energy from waste facilities and many more types of construction sites.

Typical Joint Application

- Floor slabs

- Walls

- Stairwells

- Corbels

- Diaphragm walls

- Jumpforms

- Brick support ledges

Maintain Robustness Of Your Concrete Joints

Let Us Drop You A Call For Consultation. For Free.

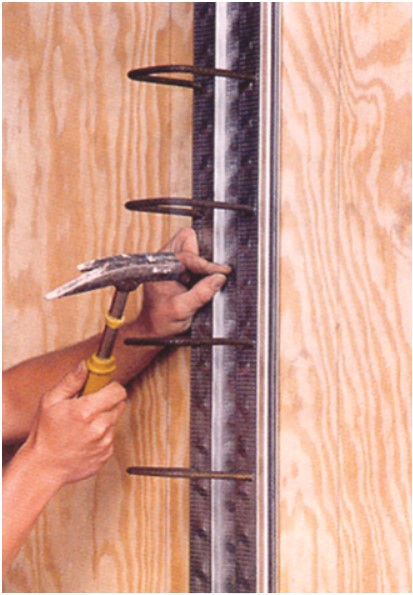

How to Install MOMENT Bar Box?

Step 1

A MOMENT Bar Box unit is installed by firstly nailing through the casing to the shutter face. The casing is annealed at points to make this operation easier.

Step 2

With the Bar Box unit securely in place, concrete can be poured and the entire unit will become part of the first pour of the concrete and structure.

Step 3

With the formwork struck, the Bar Box lid and end caps can now be removed and discarded. The lap bars contained inside the case will now be revealed for rebending.

Step 4

Check the stirrups are completely clean.

Step 5

With the Bar Box casing opened, the lap bars can be bent out using the correct tool according to our installation guidelines.

Related Articles You May Be Interested

Precast Lifting’s Dos & Don’ts For Safety & Productivity

2 of the most challenging aspects of constructing with precast concrete are the lifting/handling and connections. In this section, we will deal with the dos and don’ts of lifting, moving and handling of precast concrete elements with regard to safety, productivity and cost-effectiveness.

This article will not cover topics such as installation or troubleshooting as those topics are already covered quite comprehensively by the individual suppliers in their literature. Instead, we will focus on the bigger picture issues that are preventing the industry from moving forward.

Traditional Methods

Still to this day, reinforcement U Bars and Post Tension Wires are still used as lifting points for precast concrete elements, but those using these types of lifting points do not understand the dangers that they are exposing the workers to. Most lifting designs do not have any built-in redundancy, so a failed lifting point will most often result in an element crashing down to the ground. Even if there are no casualties, a dropped element is often then scrapped as the damage resulting in a dropped element is too much to repair them.

The cost of using a proprietary lifting anchor is approx. 0.5% of the cost of a typical element and therefore can be considered as very cheap insurance against losing a piece of precast concrete. Not to mentions all the likely liquidated damages that could be incurred as a result.

The reason why rebars and post-tension wire are not suitable as lifting points is simply due to the fact that they are not designed for it. Both steels are designed to work in tension and although rebars can be bent, the ductility of the steel is always reduced after the bar is bent due to yielding in the extreme fibres of the steel. So much so, that there are discrete limits on the size of the radius that you are allowed to bend them to. Generally between 4d to 6d depending on the code and the diameter of the bar. Attaching a crane hook to a U Bar will result in the partially yielded bar to be further bent around a radius that is even small than those allowed in the rebar codes. Therefore the risk of failure increases significantly using either rebar or post-tensioning wire.

There are some proprietary lifting systems available in the market that seem to call this suitability in to question but to understand it fully, you need to cut through the wire and look at the cross-section. The wire products sold for lifting have a 7 strand configuration, but the central core strand is made of a fibre core and not a steel core in the case of a post-tension wire. This allows the wire to be much more flexible and bend around a smaller radius than its steel-cored cousin.

2D Lifting

There are 2 very common ways of lifting 2-dimensional panels, namely, face lifting and edge lifting.

Face lifting is where a number of anchors are placed into the flat top of an element and the concrete is lifted in a flat position. This is commonly used for staircase landings, man-hole covers and floor units.

Edge lifting is where a number of anchors are placed along the thin edge of an element so that the concrete can be tilted up into a vertical position for storage and installation. This type is commonly used for shear walls, infill walls and façade panels.

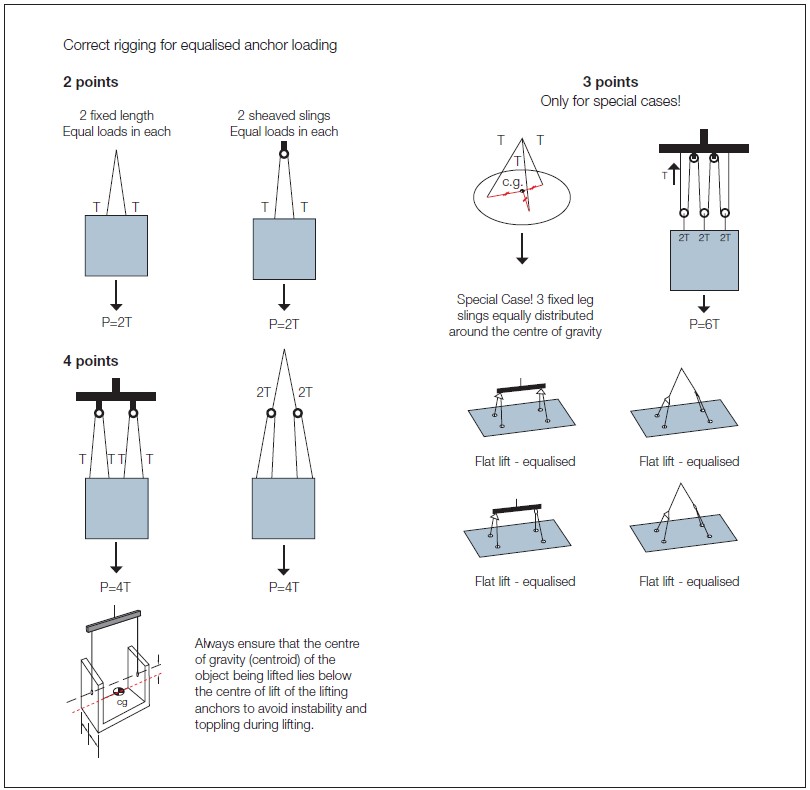

The challenge with lifting and handling all precast components is the rigging required to attach the element to the crane but still allowing for the load to be equalised across all the anchors. Some real no-no’s for this would be if fixed-length chains or slings are used, or if you try and use a multiple of 3 anchors in any one lift, so 3, 6 and 9 anchors should only be used if absolutely necessary or with very advanced rigging to ensure the anchors are fully equalised.

Never Compromise On Safety! Let Us Drop You A Call For Consultation. For Free.

3D Lifting

As we have moved towards PPVCs and PBUs the challenges associated with lifting have changed and in many ways become much more complex.

Often the element being lifted have a number of boundary conditions that we need to respect such as wall thickness, concrete weight and centre of gravity.

One of the biggest challenges associated with the lifting of these 3-dimensional elements is the weight of the element due to the availability and range of cranes available on site. There are a number of precasters exploring lightweight aggregates or the use of fibre reinforcement to reduce the weight of the elements, but many prefer to simply use thinner and thinner walls. The industry seems to be settling on a 90mm thickness for a PPVC wall, so back to back elements can provide a 200mm thick finished wall by backfilling the remaining 20mm with a cementitious grout.

The wall thickness will often mean that we need to use a lot more of a smaller capacity anchor rather than just a few larger capacity anchors. This, in turn, makes the equalisation of the loads even more challenging and most precasters prefer to use fabricated lifting frames to assist with the equalisation.

However, as most architects prefer to have a few different geometries in their buildings, it means that one standard lifting frame gets used for a variety of different geometries. Providing the frame is well designed, this can be a good way of minimalizing the capital outlay for a project, but excessive out of plane lifting should be avoided at all costs as this can result in the thin concrete wall spalling away and causing damage to the concrete or, worse still, a failure of the lifting point. Therefore the lifting frame should be designed to be as closely aligned to the wall geometry as possible.

Another challenge for 3-dimensional shapes that needs to be considered is the relative position of the anchors to the centre of gravity (COG). Providing the centroid of all the lifting points coincides with the COG when viewed in plan, then the element will be lifted flat with no tilting. However, as each PPVC might be slightly different, it is not practical to do this 100% of the time and some slight lifting or rotation is deemed to be acceptable.

One thing to be avoided wherever is that the centroid of lifting is lower than the COG. There are a number of exceptions to this, but in general, the element will be much more unstable than it would be if the centroid of lifting was above the COG.

Lifting In Thin Elements

The thin walls do create a challenge for lifting as you are required to place lifting anchors together with any required supplementary rebar (an additional bar near to, but not in direct contact with the lifting anchor) or complementary rebar (additional bar in direct contact with, or passing through the lifting anchor) into a very think section whilst respecting concrete cover and avoiding the mesh.

For Singapore, using supplementary rebars is not favoured by professional engineers, with most of them preferring to use anchors with complementary rebar, but the problem of placement still exists. According to SS EN 1992-1-1 the covered required to ensure bond transfer is just 1x bar diameter, so we only need a cover of 13 or 16mm depending on the capacity of the anchor being used. This makes it easier to fit inside the wall and transfer the lifting stresses into the concrete via bond transfer using the development lengths defined in SS EN 1992-1-1 Clause 8.4. One common trait that has been adopted by some professional engineers and needs to be stopped is the insistence on the complementary bars being the full height of the PPVC and returned under the slab at the base. This consumes an additional 7m+ of steel per lifting anchor which results in unnecessary and additional cost and additional embodied CO2 into the element which is bad for the bank balance and the environment. For a PPVC with 8 lifting points is results in about 90kgs of additional material with a cost of more than $70 per element that could be eliminated.

Health & Safety

The final, but the most important, piece of the puzzle is health and safety. At the moment, their elements are placed into position using a crane and then we need operators to climb up to the top of the element (3m+) just to disconnect the clutches and hooks. There are a number of remote release systems available on the market that contractors and precasters alike could consider and significantly improve the productivity and safety of precast operations on site.

Related Articles You May Be Interested