Accelerated construction growth demands quality connection, efficiency and operability.

In recent years, the demanding design in concrete, new materials and development of composite structures have prompted designers to consider alternatives to lap splicing or welding to connect reinforcing bars. The insufficiency of lap splicing and welding rebar is inadequate for modern construction needs. As such, gone are the days of lap joints or splices—where rebars are connected with time-consuming splicing or expensive welding. Enter the rebar coupler to provide better safety, sustainability, and, most importantly, cost reduction.

The advancement of steel thread coupler technology enables rebar couplers to bring quality connectivity, efficiency and operability to such construction needs. The rebar coupler is the perfect fit for today’s construction methods.

What are rebar couplers?

Joining rebars with couplers, which is mechanical splicing, is not foreign in the industry. However, the applications of rebar couplers are yet to become the norm.

Mechanical splicing is the connection between two reinforcing bars enabling the bars to behave like continuous lengths of rebar. Couplers, small steel connectors, are used for the connection with total tension capacity. Commonly, the threaded system is used. It’s simple, brilliant design reduces the amount of reinforcement required.

Why use rebar couplers & the benefits of a continuous rebar

Traditionally, lapping reinforcements are inevitable in concrete buildings to ease transportation and handling of rebars. The two lap-spliced reinforcing bars depend heavily on the concrete bond for load transfer. The reinforcements will be unstable under their lengthy vertical weights. Lapping is also naturally wasteful and possibly leads to heavy reinforcement congestion in the section of a concrete member. Conversely, welding bars are considerably more expensive depending on the chemical properties and weldability of the rebars. They also vary in performance as they rely on the welder’s skills and the metallurgy of the rebar.

Reduce congestion of rebars

Congestion happens in the lapping of reinforcement as the steel-to-concrete ratio doubles. It makes placing and compacting concrete challenging, which may significantly affect the structural integrity of the finished structure. Using rebar couplers eliminates this problem.

Independent of surrounding concrete

The transfer load of lap joints depends heavily on the bonding of the surrounding concrete. Hence, degradation or poor compaction could affect the performance of the splice. When the two reinforcing bars behave as a continuous unit using rebar couplers, concrete is not needed for load transfer, promoting full strength in tension.

No damage to the formwork

Previously, preparing starter bars with them projecting through the formwork generated loads of challenges. Namely, safety hazards of protruding bars, the need for perfect predrilled holes accurately positioned in timber formwork, the time-consuming process of drilling holes in concrete and filling it with resins, and many others. Using rebar couplers to connect starter bars will eliminate all of these challenges.

Save costs

With rebar couplers, construction projects use less steel. Thus, eliminating wastage and unnecessary rebar costs by up to 40%. It is also proven that rebar couplers significantly reduce construction time and reinforcing steel. Other costs rebar couplers may save include

- Material wastes from overlap splices

- Cost-efficiency on overall project costs with larger rebar size

- Rebar and freight costs

- Job site problems due to rebar congestion

- Damages on costly forms rendering the form unreusable

- Labour, designer and detailer costs

- Delayed project schedule due to installation inefficiency.

Contribute to sustainability goal

Reinforced concrete structures use enormous amounts of concrete and rebar during the construction phase. Rebar contributes the most CO2 per unit weight compared to other resources. Did you know rebar contributes about 9.2 times embodied CO2 (ECO2) over concrete? Also, mechanical rebar couplers significantly reduce the amount of ECO2 by at least over 80% compared to splice lap. Using couplers to connect rebars can build a greener and lighter building, enabling the optimisation of rebar work and achieving project sustainability goals.

Rebar Couplers Types & Application

Generally, there are many coupler systems in the market for various applications. Leviat, a CRH company, features a suite of coupler systems of industry-trusted brands such as MOMENT and Ancon.

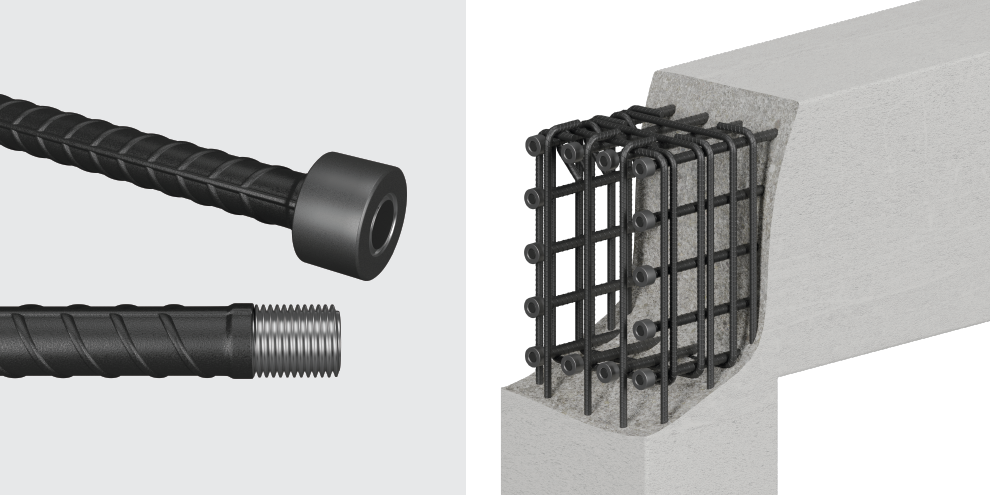

The renowned MOMENT JoinTec Coupler ensures a full performance splicing joint with its proof stressed bar ends. The extended long thread provides swift installation by simply turning the coupler instead of the bar. Its parallel thread assures a positive alignment, locking the connection and maintaining continuity and structural integrity.

The MOMENT Terminator Coupler assembly, on the other hand, eliminates congestion and placement problems in heavily reinforced compact concrete structural members in the anchorage zones, typically posed by hooked rebar embedment lengths. It can be used to fully develop the bar instantly at the surface of the head for tying pile changes into capping beams or curtail reinforcing bars.

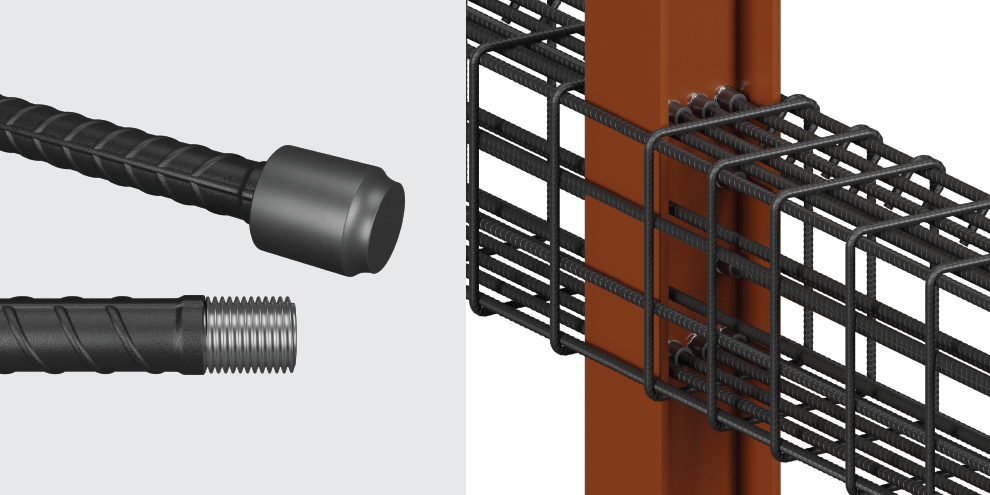

The MOMENT Weldable Coupler is designed for connecting reinforcing bars to structural steel members such as plates, piles, beams, columns, and more. It is effective and safe to connect steel and concrete when the structure is composite.

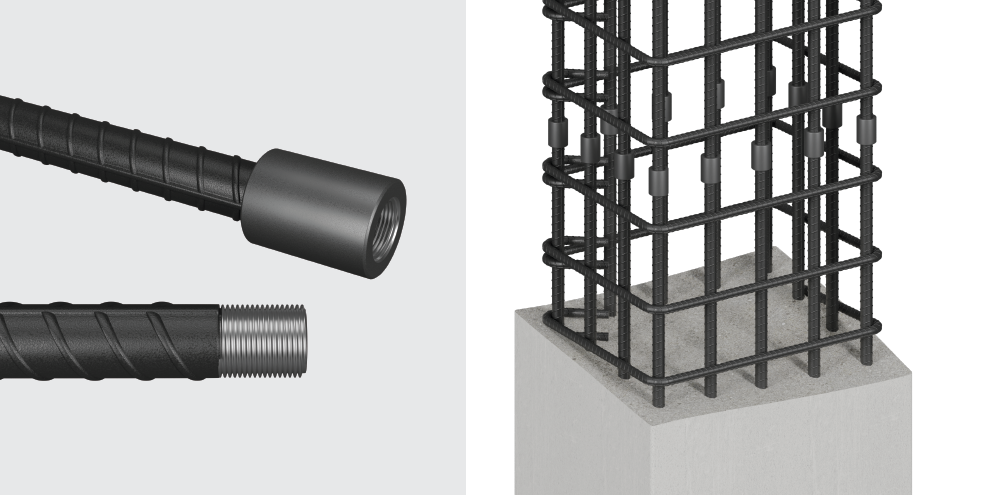

For high cycle elastic fatigue applications, maintaining values over the design strength of the bar is essential. For this, the MOMENT RT Coupler offers full strength with an alternative threading technology capable of exceeding the nominal ultimate characteristic strength of the bar.

The MOMENT Grout Coupler is uniquely designed for precast concrete connections with high flexibility and tolerance. When coupled with the MOMENT JT threaded system, and the MOMENT’s proprietary 100MPa grout can carry high loads exceeding the strength of the rebar.

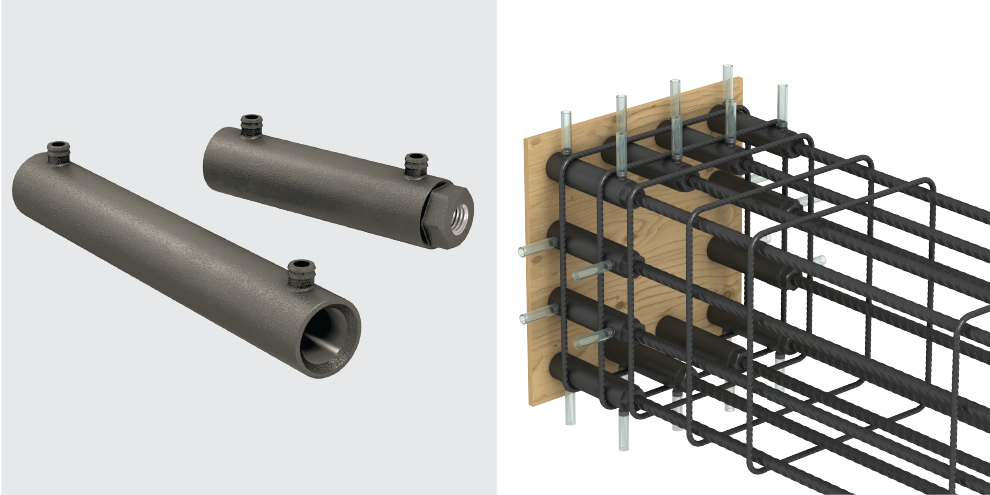

The Ancon MBT Coupler is ideal for alteration or refurbishment projects. Particularly useful when the fixed bar is already in place with insufficient space for a hydraulic swaging press. This cost-effective coupler can achieve failure loads higher than 108% of the characteristic yield strength of grade 500 reinforcing bar.

The need for a more efficient splicing system is increasing due to increasingly complex constructions and design requirements. Leviat’s reinforcement rebar couplers can simplify the design and construction of reinforced concrete and reduce the amount of reinforcement required.

How to make smart rebar coupler purchases

Here are tips on essential questions to ask before buying any rebar couplers.

1. Are the rebar couplers compliant with ISO 15835?

Suitable rebar couplers have gone through strength and slip tests according to ISO 15835. So always ask for strength, slip test reports and CARES and CREAM certifications to ensure fitness. The MOMENT JoinTec Coupler is compliant with ISO 15835 and most of the international code of practices and exhibits superior cyclic performance. It is designed to withstand an ultimate tensile strength of up to 700 MPa, resulting in Bar Break performance on most of the rebar available on the market.

2. Can the rebar couplers be traced?

All rebar couplers should carry symbols traceable to the raw materials and production batch data. Good suppliers have detailed process flow control with accurate manufacturing drawings, hold points and QA/QC measures. It ensures continuity of production and quality consistency. Leviat’s rebar couplers come with embossed serial numbers, ensuring full traceability throughout the manufacturing process from the mill through machining, processing, packaging and supply.

3. Does the rebar coupler come with a chamfered edge?

Chamfered edge helps cope with axial misalignment, providing a positive alignment locking connection and thus providing continuity of the load path. It is also safer to install a chamfered coupler, particularly when hand tightening a parallel threaded rebar coupler. All Leviat’s couplers are made with chamfered edges.

4. Are the rebar couplers manufactured using Computer Numerical Control (CNC) machines?

A fully automated CNC machine produces a highly accurate rebar coupler. It ensures the thread is centrally located in the coupler, avoiding unwanted bending MOMENTs. Also, well-matched threads are consistent compared to manual tapping, where the accuracy and quality are highly dependable on the operator. Leviat’s couplers are made on fully automated CNC machines.

5. Is cold forging part of the rebar threading process?

Cold-worked strengthening of the end of the bar ensures the tensile (root thread) reduction does not compromise the overall coupling performance. This type of coupler is ideal for geographical areas prone to earthquakes where the formation of plastic hinges is essential for structural robustness. MOMENT JoinTec Coupler systems are supported by three high-productivity machines where each bar is prepared in the sequence of clean square cut, cold working of the bar end and then threading.

6. Does the provider have a team of engineers ready to support?

From design through to the completion of your development, you will need support in eliminating problems to avoid costly delays. Ensure the provider has a team of engineers ready to assist during your project duration. At Leviat, the qualified engineers offer additional services to customers, including technical support, product adaptation and installation advice, allowing customers to reach higher productivity with less hassle at construction sites.

7. What projects have used their rebar couplers?

Ask for a project reference list with supplied products and quantities to help you make an informed decision and prepare for risk mitigation. Leviat’s rebar couplers have an established application history in Asia since 1991. Their mechanical splice systems are delivered to a diverse range of projects from national government projects, buildings, transportation infrastructures, utility infrastructures to oil and gas sectors.

Conclusion

Rebar couplers bring quality connection, efficiency and operability to construction projects while saving costs with eco-benefits.

Related Articles You May Be Interested