Ancon Unilift Lifting System

The Ancon Unilift Systems are engineered and rigorously tested under the strictest quality assurance policy, providing the safest, yet cost competitive solution to the precast concrete and building industry. The Unilift Lifting System includes:

• Lifting anchors

• Lifting clutches

• Recess formers

Cone Anchors

Cone Anchor is made of a round steel rod with a forged foot and head. Forged using special impact resistant steel, the range of Cone Anchor has been specifically engineered to safely lift precast concrete elements in the most challenging of environments and site conditions.

In the same load group, Spherical Head Lifting Anchors are available in different lengths. Longer anchors are installed for reduced edge spacing or for low concrete strengths.

The key benefits and features for Spherical Head Lifting Anchors are as per below:

• Safe, quick, efficient

• Durable clutch is resistant to abrasion

• Huge range of anchors and accessories for all types of precast elements

• 8 load classes from 1.3 to 32.0

• Ideal for beam or wall elements

Anchors are supplied with mild steel finish as standard

Reo (eye) Anchors

These anchors are used with a hanger bar, also known as a tension bar, where the concrete is too weak for a cone anchor. They are ideal for thin panels and other applications where the concrete shear cone developed by the anchor is insufficient to provide the working load limit of the anchor e.g. low strength concrete.

Reo Anchors are used with a hanger bar where the concrete is too weak for a cone anchor

The bar ends are supported within the coupler by a patented reversed teeth inner wall, and as the lockshear bolts are tightened, the conical ends embed themselves into the bar. As this happens the reversed teeth bite into the bar. The lockshear bolts of couplers up to and including the 20mm bar can be tightened using a wrench. For larger couplers, a nut runner is recommended. In all cases, heavy-duty sockets should be used.

When the pre-determined tightening torque for the bolts is reached, the heads shear off leaving the top of the installed bolt slightly proud of the coupler. This provides an instant visual check of correct installation.[/vc_row]

MBT Coupler

Section showing the embedment of the

lockshear bolts and saddles into the

bar and the shell of the coupler

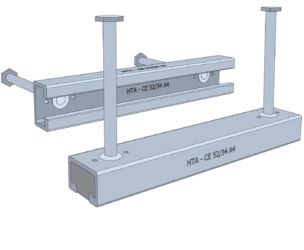

Dry connection of precast elements dispenses with grout filling the joint, substantially reducing the time and effort required for installation.

The HEK Precast coupler is a boltable precast concrete connection that uses serrated plates, which are immediately capable of longitudinal and shear loads right after installation. Furthermore it compensates for manufacturing and installation tolerances of up to 10 mm.

Advantages:

• Bolt connection

• Durable corrosion protection

• Short installation time

• No temporary bracing required

• Less crane time

• Weather independent installation

• Dismountable

Learn More Here

FRIMEDA Lifting Anchor System

The FRIMEDA Lifting Anchor System consists of flat steel anchors, recess formers and lifting clutches. The design of the lifting clutches and anchors permit loads in any direction. One of the main benefits of this system is the availability of erection anchors for tilting of thin elements with no edge breaking. The clutches can be released either directly by hand at the clutch head or by remote control.

The Anchor

The anchors are made from a special quality of flat steel. The anchor head has a hole in which the locking ring of the clutch can engage.

Ring Clutches

The ring clutch is positioned in the recess surrounding the cast-in anchor and the locking latch is closed by hand, enabling the locking ring to engage with the anchor head. The clutch is thus connected with the anchor in a matter of seconds. The ring clutch can now be pulled in all directions to allow for lifting, rotating and pitching of the unit. There is no preferred direction. To release, open the latch and the ring clutch can be removed.

The key benefits and features for FRIMEDA Lifting Anchor System are as per below:

• 15 load classes from 0.7 to 26.0

• Numerous types of anchor

• Confusion of load classes not possible, because only those components that belong together fit together

• Erection anchors protect the concrete when shear loads are applied

The FRIMEDA lifting anchor system consists of flat steel anchors, recess formers and lifting clutches

Cast-In Channel

HALFEN’s extensive range of curtain wall channels and brackets can be utilized with mullions, stack joints and transoms, which cater for all architectural and construction requirements.

HALFEN Cast-In Channel

HALFEN Cast-In Channels also known as the Curtain Wall Channels and Brackets are the ideal basis for easy-to-install, adjustable fixings, saving considerable installation time, resulting in faster construction and therefore cost saving. A PE foam or a strip filler provides protection against ingress of concrete into the channel.

Any of the following components can be fixed to HALFEN Cast-In Channel:

• Concrete façades

• Pre-cast concrete elements

• Pipe support systems

• Brickwork support

Hot-rolled HALFEN Cast-In Channels are also ideal for all applications in which dynamic loads occur, e.g. in crane rails or machines.

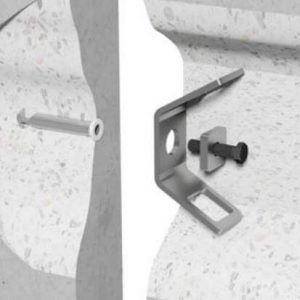

Easy-to-install, dustfree and adjustable connections to concrete

HB Anchor Bolt System

Injection system VMU

The HB-V A4 Chemical Anchor Bolt with ETA approval consists of a glass capsule filled with synthetic resin, hardener and quartz additives, as well as the HB -V-A anchor rod. The components in the capsule are mixed while the anchor rod is driven in, forming a fast-setting synthetic resin adhesive. This established anchoring system does not cause expansion forces and therefore is able to bear heavy loads even when the available spacing and edge distances are quite small. The drill hole is sealed by the synthetic resin adhesive.

Injection system HB-VMZ

The HB -VMZ Injection System consists of an anchor rod with conical expansion elements and a 2-component injection adhesive. This combination makes it possible to transfer heavy loads into the base material while maintaining small spacing and edge distances and sealing the drill hole. It thus combines the advantages of chemical anchors and wedge anchors in a fastening system for cracked and non-cracked concrete with technical approval for Europe. Where up to now fasteners were not permitted because the concrete component was not thick enough, it is now possible to use the HB-VMZ Injection System.

Even in wet drill holes it is possible to fit all sizes of anchors without any reduction of load-bearing capacity, from anchor size 100 M12 even in drill holes filled with water. An outstanding feature is also the approval of the HALFEN HB -VMZ Injection System for installation at temperatures down to -5 °C. This system can be installed in nearly all weathers and at any time of year. This very comprehensive product range, which comprises all sizes from M8 to M24, combines optimum size and fixture thickness resulting in considerable cost advantages, particularly in larger projects.

Learn More Here

HALFEN DEMU Fixing Anchors

Examples for typical application:

• Structural steel connections

• Fixing of railings for balconies and bridges

• Fixing of props on precast elements

• Fastening of utility equipment, power lines

• Securing lightweight ducts, lighting or wiring

• Fixing of steel ladders, stairs and profiles

DEMU Fixing Anchors may be used in cracked or non-cracked concrete for transmission of tensile loads, shear loads or a combination of both

Learn More Here